Lathe conversion to CNC -3 Ball Screws

by John

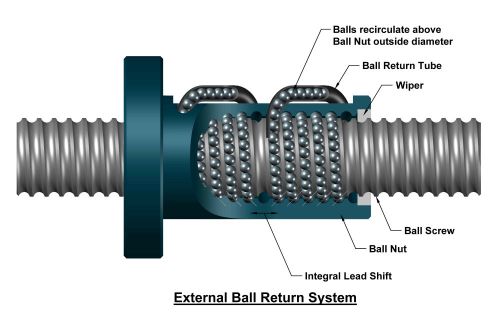

I have learnt a lot about ball screws in the past few days. And I have purchased 2 ball screws and nuts on Ebay. For those relatives and friends who follow this post, who have no idea what I am talking about, the “ballscrews” are what determines where the cutting tool on the lathe is positioned. Very crucial. (can something be “very” crucial? It looks a bit like “very unique”. )

Ball screws are the usual positioning screws for CNC machines these days. The alternative is Acme or square thread screws, but the few manufacturers who used to use these have all switched to ball screws (as far as I know). Even Wabeco, the respected German lathe manufacturer no longer specifies any threads except ball screws.

Ball screws require less power to turn due to friction being a fraction of the alternatives. Ball screws are silent. If they are noisy there is something wrong. They are generally more accurate than square or Acme threads. They used to be many times more expensive than the older types, but since China/Taiwan has taken over most of the manufacturing, often using equipment sourced from US/Europe/Japan, the costs have plummeted.

And the backlash is minimal or zero. Another name for ballscrews is “antibacklash screws”.

Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. Interestingly, it is less important on the CNC lathe lead screw, because most CNC lathe machining on the leadscrew occurs in one direction only, towards the headstock. However, the cross slide is machining in both directions, in and out, so the absence of backlash is necessary to maintain workpiece accuracy.

Ballscrews have grades of accuracy varying from C0 -C20. The bigger the number, the less accurate the screw. In general, it is recommended that industrial lathes should be C3-C5, which means zero backlash, and accuracy of about 0.001mm. That degree of accuracy is quite expensive, costing thousands of dollars per screw, and only attainable in ball screws which have been finished with precision grinding. The alternative is ball screws which have been “rolled”. These are much less expensive, costing hundreds of dollars per screw, depending on the degree of accuracy. The best rolled screws can attain an accuracy of 0.01-0.02mm (C7), down to 0.1mm (C20). These are approximate figures which I have gleaned from several manufacturers’ specifications.

So from scale drawings of the lathe bed and carriage and cross slide, I worked out that I needed the following…

This is a photo of a ball nut and screw very similar to what I have bought for the cross slide. THK brand, 14mm diameter screw, 4mm pitch, and BNT nut style. Note the rounded channels that the balls occupy.

- Cross slide screw 14mm diameter, 400mm long with at least 200mm of thread, and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a minimum of space making machining. THK is a large manufacturer, with intermediate prices, and a very good reputation. The screw needs to be a specific length, and one end needs to be machined to go through a bearing/ bearing housing and have a tooth belt pulley attached. I contacted a ball screw supplier, to enquire about ground ball screws, but discovered that these were rarely specified due to their cost, and delay of 3-6 months. A C7 rolled screw with the BNT nut was going to cost about $AUD400-450. So I searched Ebay Australia, Ebay USA, and Ebay UK. Eventually, I found and bought a used ground screw with end bearings and housings from Taiwan for $AUD250. The nut was the wrong type, but I found a new correct style nut on Ebay USA for $AUD100. I know that sounds like I have not saved much money, but that gives me a super-accurate ground ball screw! Of the correct size and type. I am keeping my fingers crossed that the pieces sourced from different countries will go together. Theoretically, they should. (same manufacturer, same size, “ground” specification, etc etc. but finger tightly crossed).

- The lead screw approximately 1000-1100mm long, 25-32mm diameter, and 5-6mm lead. Super accuracy not required in the lead screw, and I could have bought a new rolled one from China for about $AUD300-400. But then I spotted one in South Korea, new old stock, 28mm diameter, 6mm lead, with unmachined ends. THK brand. Asking price just within budget. And this was a C5, ground screw, possibly more accurate than I expected for the price, and unused, but hey, it sounded like a bargain. So I offered about 15% less and was somewhat surprised to have the offer accepted. So that one is arriving in a week or two. Then to buy mounts and arrange end machining of the screw. Although not crucial it will have zero backlash, due to the C5 designation, and the fact that it has two ballnuts bolted together in a “pre-loaded” fashion. I expect that it will be the most accurate component on the lathe! No decent photo to post.

(ps. see the comments section for discussion about axial accuracy and backlash. A super accurate C5 ballscrew has axial play (backlash) specification of 0.020mm, but the double ballnut configuration will reduce that number substantially. “zero backlash” apparently does not really mean zero.)

I had no idea what a ball screw was until I read your post, which I found fascinating. What precision! I hope all the parts fit.

LikeLike

me too!!

LikeLike

I thought all ballnuts were preloaded so all ballnut/leadscrew systems do not have any backlash. The C number shows the accuracy of the leadscrew ie max deviation per unit length.

john f

LikeLike

Hi John, from my reading…

C7 and higher numbers have no preload. The Hiwin ballscrew tech data manual quotes page14 “If zero play ballscrews (no backlash) are needed, preload should be added”.

The C number does indeed refer to axial accuracy by definition, (I will correct my blog) but axial play is also impacted, albeit at very small numbers. eg AP at C0 is 0.005mm at C5 is 0.020mm and I cannot remember where I saw the C10 and C20 figures but they were around 10 times higher. Quite surprising.

“antibacklash” screws is still a relative term.

John

LikeLike