Back in the workshop, a Lathe Problem…

by John

I have a problem with my big Chinese lathe. I was hearing a KNOCK-KNOCK-KNOCK as the main spindle was revolving at low speeds with one setting of the gears.

It is a GBC 1000-400 lathe, meaning that it has a maximum of 1000mm between centres, and it will turn a 400 mm disk. It weighs 2 tons. Has been quite useful when turning flywheels, big lumps of metal, large pieces of wood and so on.

So today I removed the cover from the headstock and had a look. The cause of the knock was quickly obvious.

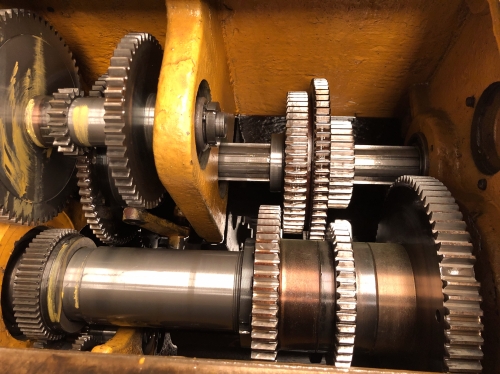

The headstock of the GBC 1000-400

The big gear on the main spindle at bottom. See the broken tooth? The meshing gear is intact.

So, what do I do about this? I need some suggestions, people.

Thoughts so far….

- remove the spindle, remove the gear and bronze braze a replacement piece of steel or bronze, then machine a new tooth.

- same as 1, except use silver solder.

- same as 1 or 2, except do the job insitu (after draining all of the gearbox oil, and screening off the other headstock parts). Unfortunately the missing tooth is close to the headstock case, so filing or grinding a new tooth would be tricky.

- leave it as is, and just avoid using that gear. I can do that. It removes 3 of the 9 gear ratios, including the slowest speed (40 rpm), and is not an elegant, or desired solution.

So what do you think? The gear is most likely made of steel rather than cast iron, from its appearance. The base of the break is shiny, smooth and not porous.

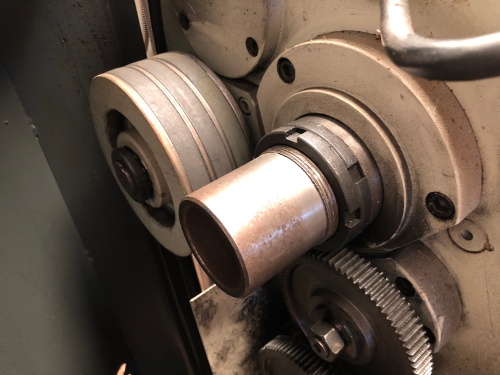

Here are some pics of the ends of the main spindle. It does not look too complicated to remove the main spindle, but what would I know.

The main spindle is the one in the centre.

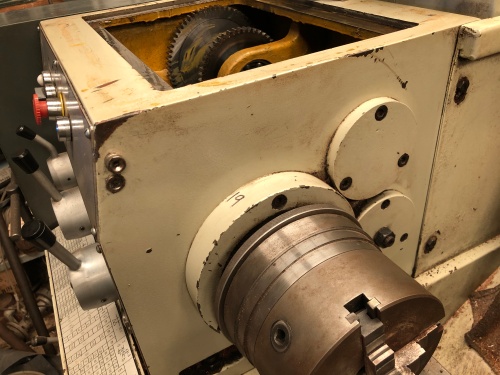

And the other end, with a self centering 4 jaw in place.

I imagine that the main spindle bearings will be pre-loaded, tapered, roller bearings. I certainly do not want to damage them. And how difficult will it be to reinstall the bearings and main spindle? I imagine that it will involve some careful and precise work. Am I taking on a job which is way beyond my abilities? If anyone has experience of this task I would be delighted to hear your views. I have no drawings or plans of the headstock to assist.

(In parentheses, when I was a teenager, I remember my father pulling a Toyota Crown automatic gearbox to bits, identifying a fault, and fixing it. There were bits of the gearbox everywhere. But he fixed the problem. He was not a mechanic, but he had a go at things, and usually managed the task, as in that case. Similarly, I dont mind having a go at this lathe job, but I would prefer not to risk destroying the lathe, so any expert opinions will be welcome. Option 4 above remains a possibility.)

With what you have done and shared here you are capable enough to do the job. I had to replace a bent spindle on a similar lathe. Resetting the preload on the spindle bearings is not that bad. You run it a good speed and let it warm up to operating temperature, then tighten the nuts up a little past where you can not measure play if you push it with a screwdriver. Then during the first real uses make sure the bearings are not getting hot. One issue you may run into is the gear/s being pressed onto the spindle.I put together a puller that was a piece of allthread through the spindle and welded up a frame to push on the face of the head stock as close to where the gear was pushing to make sure that I did not brake the head stock. I think I heated up the gear the first time I pulled it apart. Got to do it again once the new spindle bearing finally came in. I don’t know that brand, but you might check what one costs if it is available.

LikeLike

Thanks Chris. That is just the sort of information and encouragement that I was fishing for.

LikeLike

Hi John,

In the past I have tried brazing a tooth on a heat from the transmission on an old lathe’s “back gear”. It held up only a short time and then the tooth broke off again.

I eventually just replaced the gear.

That said I always wondered if I could have built it up with steel, using a TIG welder, then ground it to size.

I am looking forward to your visit next month.

Jenny

LikeLike

Was the brazing bronze or silver? And why TIG? Wouldn’t MIG or arc work? (just asking). And me too!

LikeLike

I used bronze when I brazed it.

guess you could do it with any method to get some steel where you need it. I prefer tig only because of the great control you get with that mode.

LikeLike

And less heat input too! But multiple teeth involved makes this method problematic. I will buy a new replacement if i can find one.

LikeLike

I forgot to mention in the post that the gear appears to be made of steel, not cast iron. That would improve the chance of the repair working.

LikeLike

I like the sound of this one, and others whom have similar ideas, build up the steel tooth with a weld of some sort then with a fine tool perhaps Dremel grind it to shape. I think a man of your capabilities would already know about heat and hardness.

LikeLike

Multiple teeth involved, makes this less of an option unfortunately. But thanks for the thought. John

LikeLike

Hi John,

With my advancing years (and the occasional broken tooth) I like to keep my eye on my main game namely trying to produce little pieces of mechanical jewelry (like your various engines).

The challenge of repairs is interesting but as I regard my machines as servants of my “main game”, I would have a qualified mechanic do the work thus avoiding delays, surprises or distractions.

No right or wrong here, just my approach these days.

Kind regards,

Tim

LikeLike

Hmm. I just imagine the old man watching from above…. “go on son, you can do it”

LikeLike

Morning John, Your blog wont accept my URL –

Have a good day, Stuart.

>

LikeLike

Hi Stuart, my email is jviggers@iinet.net.au

LikeLike

John

If the genre are sainted I doubt they can be soldered. The metal will have a grainy appearance. If machined have they been hardened? Not likely. You need to remove the parts and it may not be that bad.

LikeLike

genre? sainted? auto spellcheck at work?

LikeLike

you could send it to my email. jviggers@iinet.net.au

LikeLike

I would certainly remove the spindle for this job. Tig welding would certainly be the best, if for no other reason than minimizing the heating of a heat treated gear. You might need a good puller as well even if you have to hire it. I would also closely inspect the other gear teeth, on this and it’s “Meshmate” as this is likely only the first of a number on the way out. You may end up with no choice but to replace the gear.

LikeLike

OK, thanks Stuart.

LikeLike

To get a range of speeds you could always use an inverter drive & leave well alone,provided the missing tooth is not going to find its way between some other vital part

LikeLike

Hmm. Will consider that one. Would impact on threading options

LikeLike

Hi John what ever you do crack test the opposite gear and the one you repair or replace these gears dont break for no reason . When we used to set up preload on gearboxs that needed it .We used a measurement of .001″ per inch of shaft diameter preload.

LikeLike

Sounds sensible Rod. Apart from inspection, how do you crack test a gear?

LikeLike