Making a Tree

by John

The adequately sized vacuum chamber arrived today, much more quickly than I expected. Initially it would not seal and I could see no holes or leaks. But when I removed the silicon gasket I found a small silicon flake which was the problem. Thorough cleaning, and all was well.

The 1/4hp vacuum pump on the left. The new 5 gallon chamber hooked up. And the too small 3 gallon chamber on the right. I have an idea for using the smaller one, so will hang onto it.

With this arrival I am almost fully equipped to start casting. So today I built 2 trees.

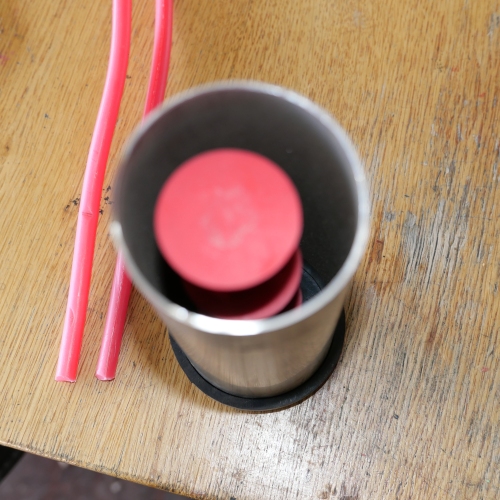

The first tree has no branches, so it is more like a tree trunk. The red items are plastic models of the central pivot column on the Armstrong model gun. Glued together with wax which I melted with a soldering iron. (soddering iron for American readers). And attached to a wax stick which inserts into the rubber flask end at the bottom. The actual steel flask is behind.

And here is the “tree” trunk in position inside the flask, ready for the investment plaster to be poured around it. After pouring it sits and sets for a couple of hours. Then after removal of the rubber end, about 8 hours in the kiln to melt out the plastic and wax. Then the molten metal pour.

This is the second “tree”. Wheel forks for the cannon chassis. Wax glued to the central wax tree trunk. The 4″ steel cylinder behind.

Preparing the moulds, and the metal pour will probably occupy about 10 hours, so I will need a totally free day. Maybe Thursday.

Wow John!

You really have got into casting in a big way. You certainly do not mess around when you indulge in a nes facet of the hobby.

Well done.

LikeLike

At 70 no time to mess around! And thanks.

LikeLiked by 1 person

very impressed with your set-ups, it does make a huge difference with the right gear, i have to make do, which usually ends in more stuffing about than required, good luck with the pour. On the subject of fixing imperfections in surfaces, I have found that painting never covers any surface marks, gloss paints only seem to highlight them! I use a smear of car body filler to fill dents and then a coat of filler/putty primer for the fine scratches. Will your paint be matt or gloss, not sure what the original finish/colour on those cannons was.

LikeLiked by 1 person

Yes, I have tried to find out about the cannon finishes, but without success. I imagine that any weapon would have had a matt finish, to reduce visibility. Not really decided yet on colour, but open to suggestions. John

LikeLike