CNC Mini Mill-5. Chinese Parts.

by John

The mill is almost completely assembled. Just waiting for some small connectors to arrive so I can fit the trapezoidal screws and their nuts.

Meanwhile, a couple of hiccups.

Here I am drilling the X axis plate with a 2.5mm bit. This was an awkward part to position accurately, but with the above setup the first hole was drilled successfully. But just as I was about to retract the drill from the second hole, the bit broke! I had used lubricant, and retracted several times, but aluminium is sticky, and the bit end was embedded beyond reach. Long story short, nothing worked, including trying to drill it with a carbide cutter. Eventually I drilled a hole just beyond the end of the bit, and levered it out. But the hole was distorted, and unable to be tapped accurately, so I embedded a nut in a machined pocket and that worked OK, but it looked out of place.

That plate had taken about 3 hours to make, drill and tap all of the holes. But I was not happy. So next day, I made another one. With the experience gained from the first one, the second plate was made in only about 1.5 hours. So I set it up to drill those holes in the end of the 388mm long plate. And bugger me, the drill broke again!!! Stuffed around for a while, but no luck extracting the broken drill, so I made another X axis plate. This time I drilled the end holes, and tapped them first. No problems this time. Then finished the rest of the plate in under an hour. Installed it. All fitted well.

So that was the only significant problem in the build so far.

Then a package of parts arrived from AliExpress, including hardened steel rods, linear bearings, ball bearings trapezoidal screws, and nuts for the screws and some more. I have previously had only good experiences buying vis AliExpress, but this lot had some disappointing quality issues.

First, I noted that the bearings seemed to be a bit sloppy on the 8mm steel rods.

The 8mm steel rods were actually 7.97mm, more than 1 thou undersized.

Then I noted that all of the 400mm steel rods were bent, quite noticeably. OK, maybe not too disastrously, but not up to scratch for a supposedly precision item. I will probably be able to straighten them well enough to use, but not what I expected. They were packaged in bubble wrap inside the soft envelope. But surely a hardened, polished, supposedly precision made rod would have warranted a more substantial container.

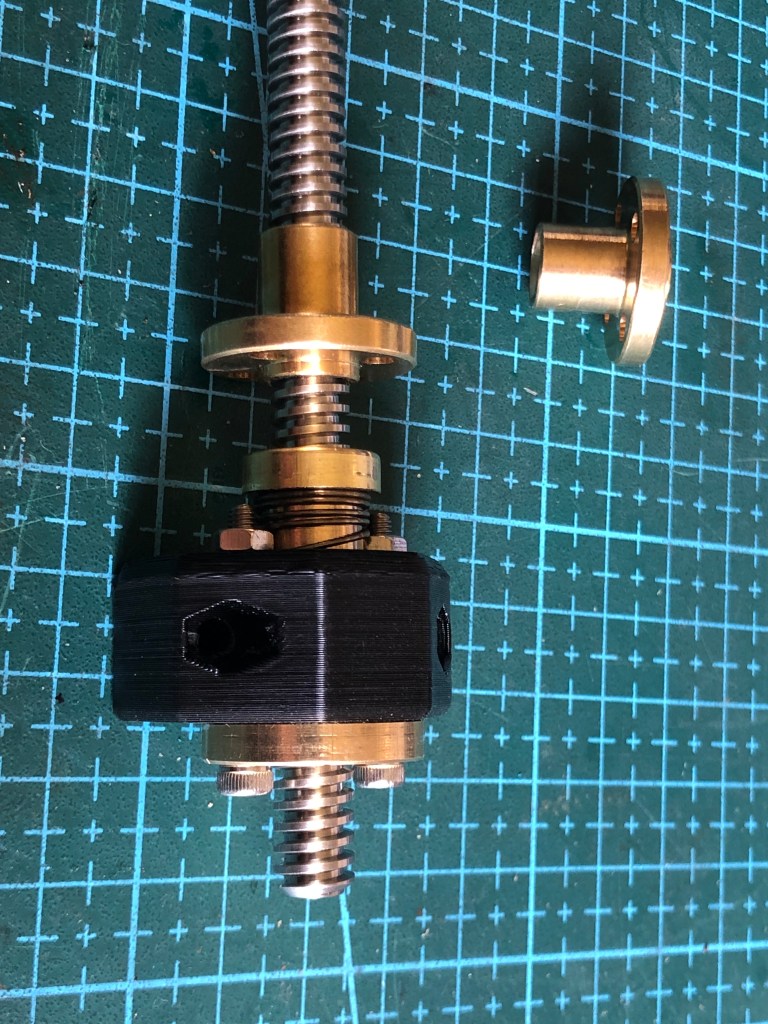

Then I checked the trapezoidal screws and the nuts. The nuts were quite markedly wobbly on the screws, with an excessive amount of end play. Very poor quality! I had separately ordered some spring loaded anti backlash nuts which should be adequate for the job, but if I was relying on the nuts supplied with the screws I would be really pissed off. At least the screws were not bent, which makes me think that the bends on the steel rods did not occur in the postage but was a manufacturing fault.

I have requested that the steel rods be returned to AliExpress which would result in a refund ($AUD52), but on reflection I will probably not proceed with the return. I have another project in mind where the undersized rods will not matter. (the rope seizing and serving machine for model ship ropes).

If you’re making a machine to make other machines .03 mm is a lot of play. I wish the US had switched to the metric system back when I was young. I spent way too much time over 50+ years as a designer dealing with the United States Customary System which is based on the traditional Imperial Measurement System that the UK gave up 70 years ago.

The U.S. is one of only three countries in the world that primarily uses the imperial system, along with Liberia and Myanmar. Is that crazy or what?

I can’t wait to see your rope winding machine. Will you make a miniature rope walk for it? (lol)

Aloha, Richard

LikeLike