USING THE MINI MILL

TURNING SPARS WITH HEXAGONAL (or any number of facets) CENTERS ON THE MINI MILL

The mini mill can be used as a 3 axis mill to make 3d parts, but the 4th axis with tailstock also enables it to act as a small lathe.

The 4th axis, as set up, cannot rotate much faster than about 120rpm, and the rotating motor is not particularly powerful, so it requires the Proxxon spindle with a small (3.125mm) sharp cutter, running at about 10-15,000 rpm to actually remove material.

The first use for which I have used it is to make the spars for the Mamoli Constitution.

The model spars are 3-8mm diameter, and up to 300mm long. the larger ones have a larger diameter central section which is hexagonal or octagonal in section. The Mamoli plans specify that 1mm strips of wood are glued around the middle section, but I believe that in the ship these were often solid, part of the same logs as the rest of the spar.

So, I decided to use the mini mill to make my spars from solid material, including the central hex section.

Some time was spent becoming familiar with the commands to run the mini mill as a “lathe”, but eventually I worked it out.

The dowel was cut to about 20mm longer than the finished spar, so 8-10mm could be held in the collet chucks in the headstock and tailstock. The center of the spar was marked, and protruded about 10mm beyond the headstock chuck.

Then the end taper was cut using G code commands.

The spar was then turned around., again held in the center section, and the other end taper was cut.

Because I was using a 3.125mm cutter with a 0 degree cutting angle a shallow spiral mark was left on the surface of the tapered spar, but that was quickly sanded away after the milling was completed.

The next spar was longer (262mm) and had the hex section in the middle. Since ER collets will happily hold hexagon or any other polygonal shape, I elected to make the hexagon cuts first and cut the end tapers last.

photo 1 shows a 4mm dowel held in the ER collets, and cutting an end taper using a 3mm cutter in the Proxxon spindle.

photo 2 is the larger spar with the hex section already cut and held in the headstock collet, and cutting a tapered end. The spiral shallow groove is clearly seen. That would not be seen with a more suitable cutter eg a ball nose or using a faster spindle speed.

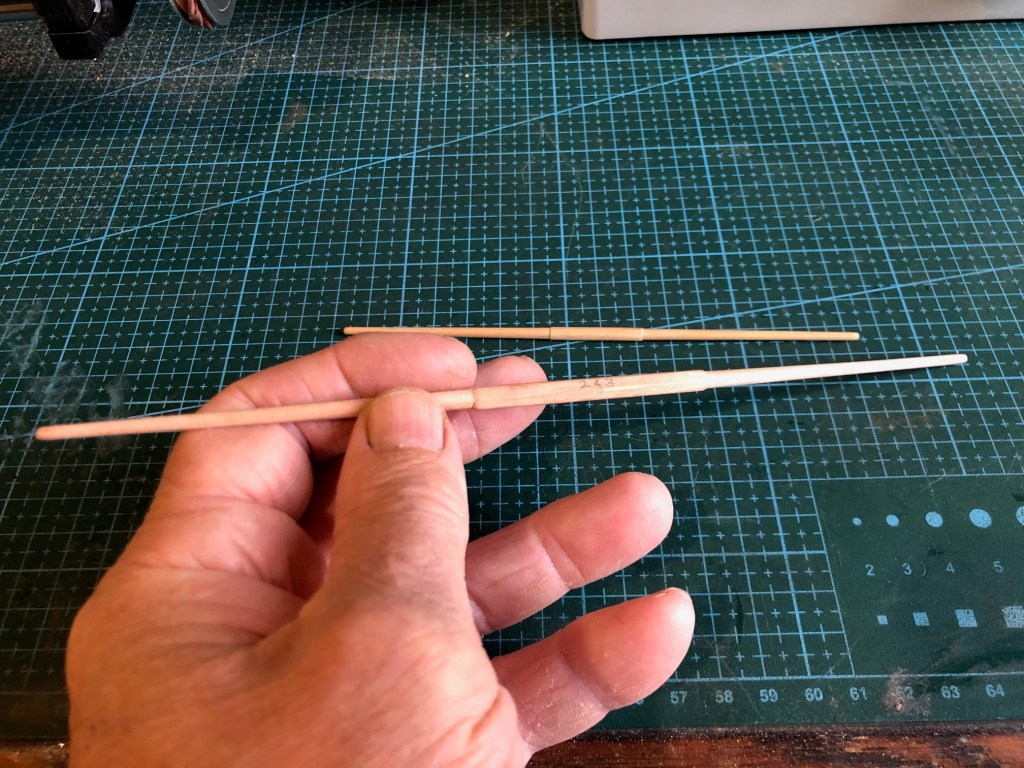

The first 2 Mamoli Constitution spars

Sorry. Pics a bit mixed up but you probably get the gist. But it does show that the mini mill does work!