CNC SERVING MACHINE- an improved bobbin carrier.

by John

Just a quickie.

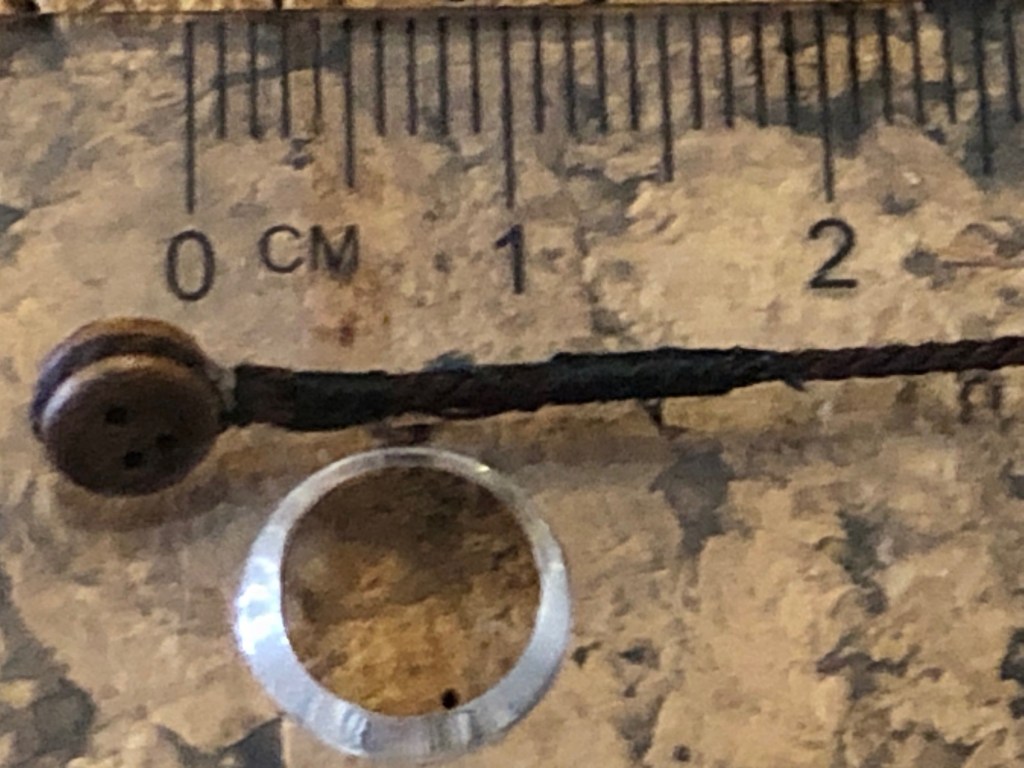

I had decided to make another top plate of the bobbin carrier out of metal because the 3D printed top was slightly rough and had a tendency to fluff up the serving thread. Metal could be polished more smoothly. Also, to seize deadeyes, (see pic below) the thread hole needed to be extremely close to the edge of the top so it almost touched the deadeye held in the chuck.

So, I made an entirely redesigned version of the carrier. The body is 3D printed, the top is cast iron; it has thread holes in the center of the top plate and on the extreme edge. Also I decided that the carrier could be narrower, enabling longer lengths of rope to be served. That was achieved simply by positioning the bobbin vertically, and 3D printing a new frame.

The new bobbin carrier on the left, old one on the right. The 3 small bobbins might be used to see if the machine can manage to do worming. Not tried that yet. The new one has a metal top (under the Lexan). The 3D printed frames are great to quickly test new ideas, but in fact are so rigid that they will continue to be used longer term.

Hi John,Still enjoying all the updates, I really envy the skills you have. More than you could believe. Anyway, I shall carry

LikeLike

Hi John, Really enjoying following along all you threads. The deadeye seizing would look a lot better at 1:1. That looks like 10X on my monitor.

LikeLike

Always enjoy following your blog. The seizing on the deadeye would look way better at 1:1 where on my monitor at least it seems 10X. Hey, 1st try plus a bit of finessing on try 2 or 3 only get better methinks.

LikeLike