More Making Model Rope

by John

I had noticed something a bit odd when making ropes on my homemade ropewalk. It appeared that the threads were lengthening at one stage. That should not happen.

So, I examined the Gutermann thread under a microscope… Gutermann is the brand recommended by most model ship authorities, or at least ones to which I subscribe. It has less fluffiness than other brands, and a nicer, smoother, slightly shinier appearance. It is also 4-5 times more expensive than other brands.

When I examined my previous technique for operating the rope walk it was obvious that I was untwisting the Gutermann thread during the initial phase of model rope making.

So today I examined every step of the rope making under a microscope.

That is a completed rope. Now to consider the stages of manufacturing a 3 strand rope, with 2 threads in each strand. ie. a 6 thread rope. We ignore the 2 strands which are now visible in the Gutermann thread, but we will take into account the Z twist which Gutermann puts into their thread strands.

Then I turned on the looper, and I made sure that I was following the same Z twist so threads were not untwisted. I was aware that this was NOT what I had done previously. The threads showed no tendency to lengthen, but started to progressively shorten. I continued until they had shortened by 250mm (about 10% of the overall length of the ropewalk.

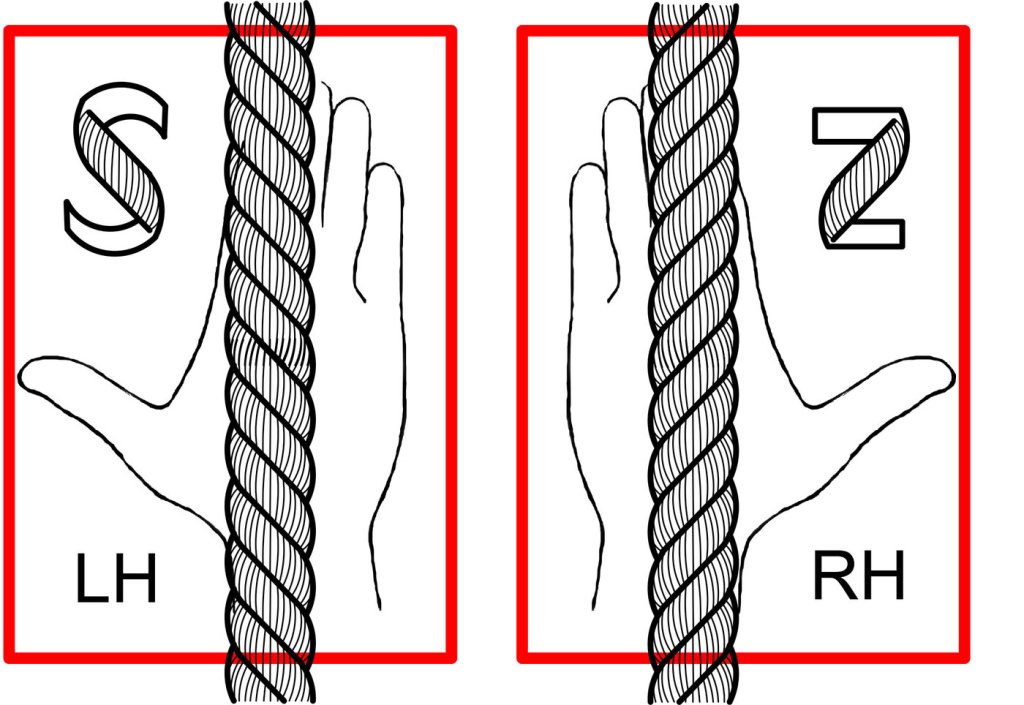

Then when the threads showed approximately a 45degree twist, the looper was turned off and the other end motor was turned on to combine the 3 looped threads. Note that this is an S or left hand twist.

The ends of the rope had a drop of CA glue to prevent unravelling. If the two twist directions are approximately balanced , when released the rope will not try to unravel. The grid marks in the photo are 0.5mm apart. The rope is 0.66mm diameter. The S (left hand) twist will not be visible at the scale. But it will be correct for the standing rigging on Constitution. If I continue to use only Gutermann thread however, ALL rigging, standing and running, will be left hand.

I bet that no-one notices.