A Home Made Disk Sander

My recently made drum sander thicknesser was quite satisfying and successful. And I was particularly impressed with the Chinese made variable speed 750w motor.

My next model builds will include a 74 gun ship, from scratch, and I am sure that the drum thicknesser will get plenty of use.

A recent visit to another model shipbuilder, Pat, and a tour of his workshop left me drooling. One item particularly impressed me, and that was his Jim Byrnes disk sander. It is quite compact, very solidly built, variable speed, and has a solid tilting table.

They are no longer made, and second hand examples are rare here in Oz, and quite expensive. Ebay US has examples in the $usd 2500-3000 range. Plus shipping to Australia. (p.s. I read in “Ships of Scale” that Byrnes Tools is recommencing production of some of their machines in 2026.)

For obvious reasons I decided to make my own disk sander. I have a 12″ Hairy Forbes version, and it works quite well, but is too big, too noisy and too messy to use anywhere except in the outside workshop.

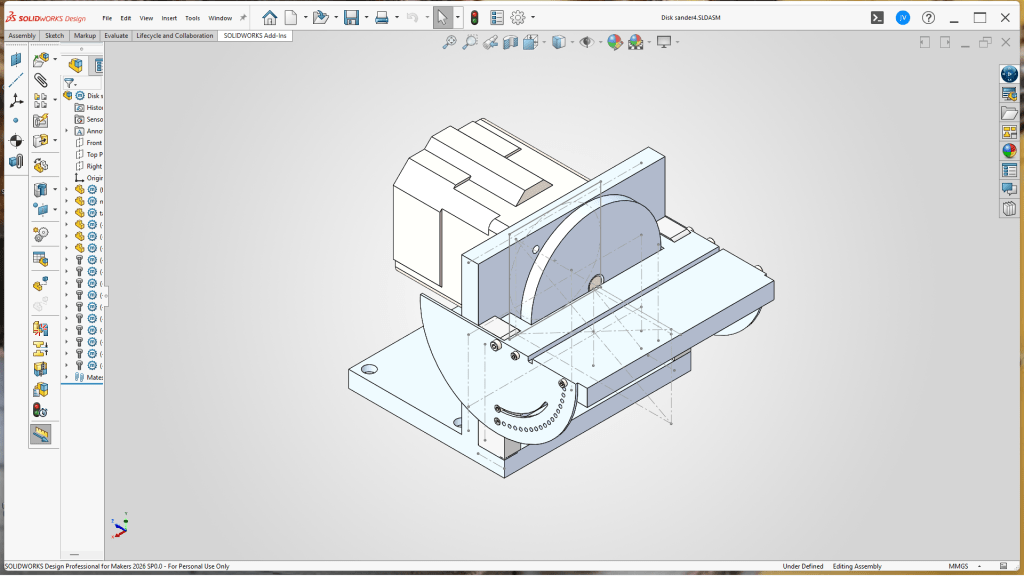

So I spent some time on Solidworks drawing up my Byrnes inspired, smaller version…the tilting table is 75x180mm.

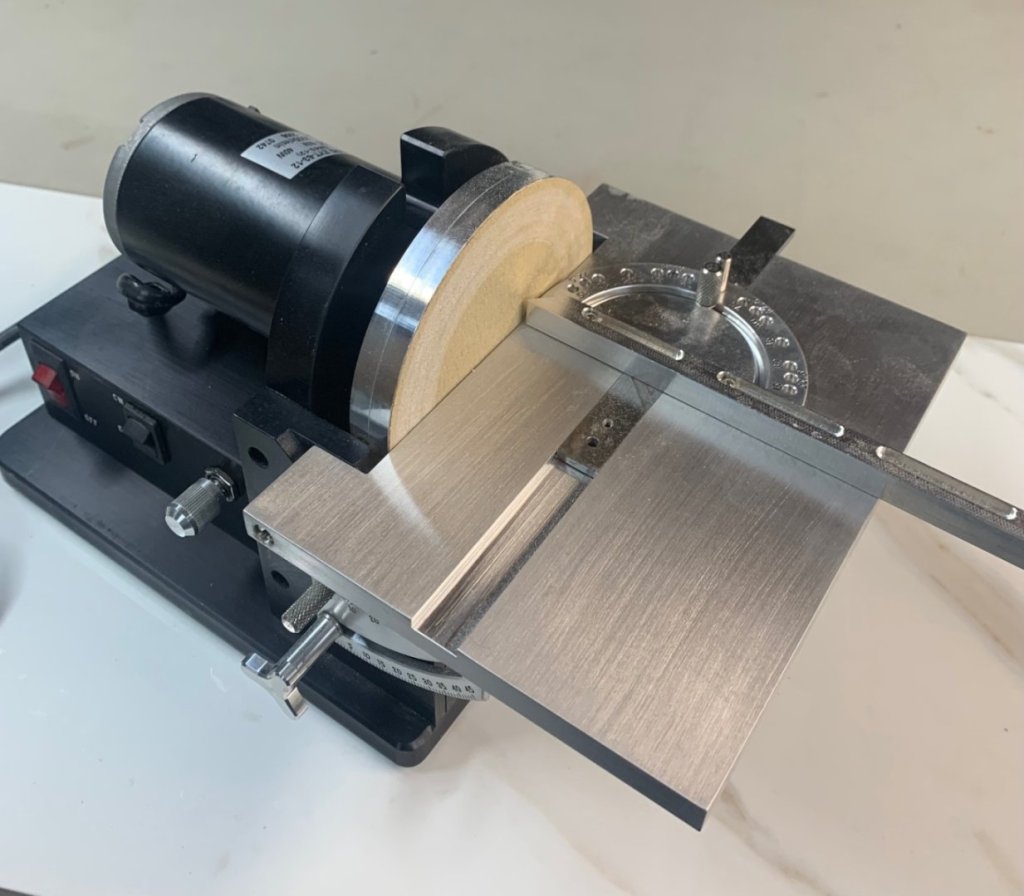

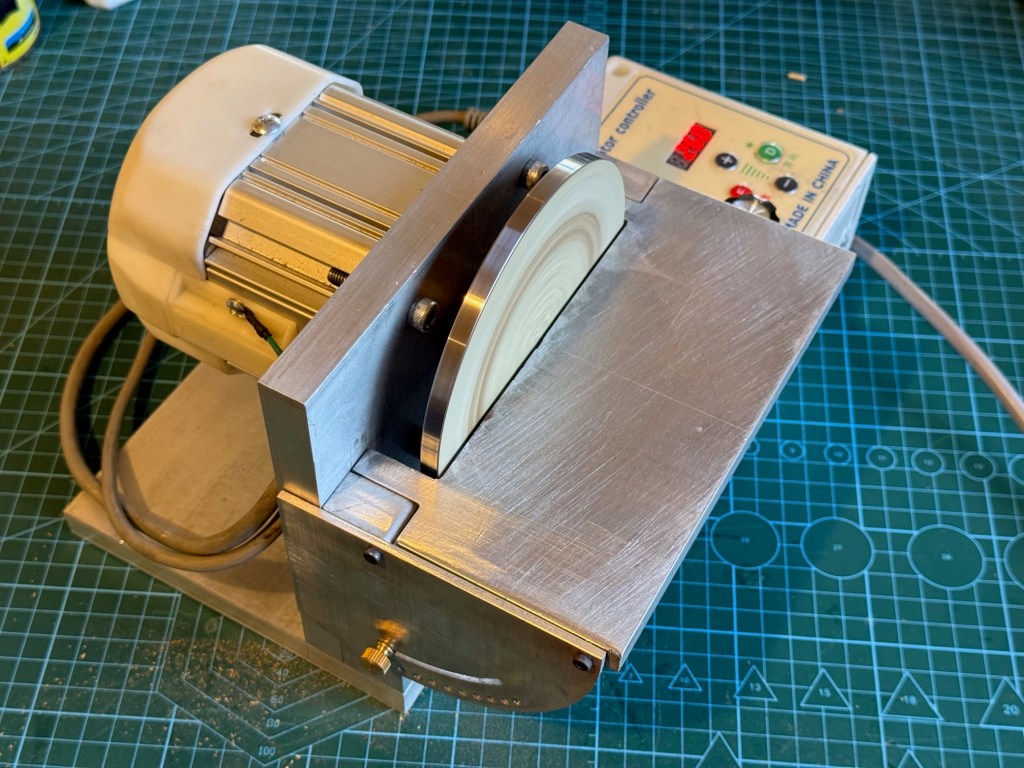

And after a few days in my workshop, here it is, (not quite finished but useable)…..

My version has a variable speed (0-4500 rpm) and reversible 1 hp servo motor, a tilting table graduated in 5 degree pinned steps, plus 0-45 degrees variable, and generally very compact and easily set up. I will get around to making an angled fence in a slot similar to the Byrne model in photo 2. I will also make provision for attaching a vacuum hose. The sandpaper disk is self adhesive and easily and quickly changed.

I made 2 disks. The first was aluminium, but I was not satisfied with it, so made the one shown from mild steel. The boss was silver soldered to the disk, and is held to the shaft with 2 grub screws. It runs very smoothly up to 2000rpm, but the unit needs to be fastened to the workbench at higher speeds. I think that most work will be done at 1000rpm. The 1hp motor is almost impossible to stall, even with big stock firmly applied.

The aluminium structural parts are 16mm thick, and held together with 6mm cap screws, so it seems quite solid. Again, the alu is all from my workshop left overs. So it has been a relatively inexpensive build. Only outlays were the motor ($aud150 approx), and 50 sheets of self adhesive aluminium oxide disks ($aud50), all from China.

I do enjoy making my own machines.