Disk Sander Dust Tray

by John

Several readers have asked about management of the dust, and since this sander is to be used on my modelling desk in the TV room, with SWMBO in the background, yes, I have had this on my agenda.

I performed a test to see whether a simple collector would be adequate, and demonstrated that a vacuum suction would be required.

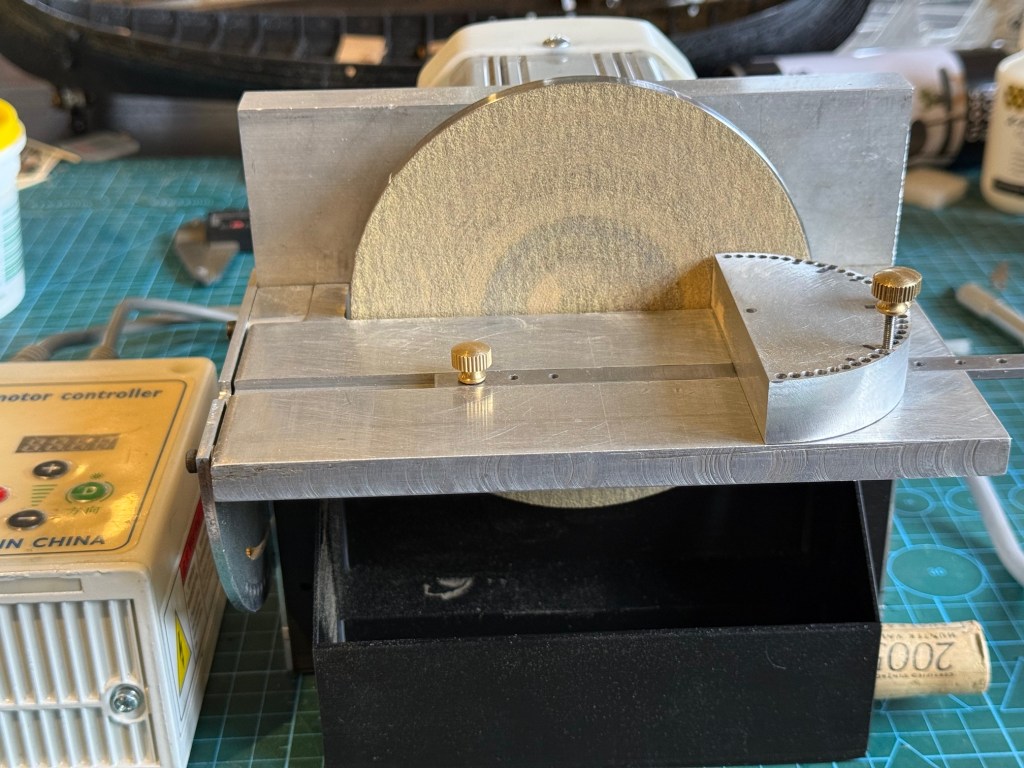

So the dust collector needs to be collecting most of the dust and able to accept a vacuum connector. And to not interfere with the tilting table or the disk with the sandpaper attached.

So, it was going to be a complicated little collector. I had hoped that an aluminium plate bolted in position, with a suitably sized hole for the suction hose would be adequate but nothing I designed or tested seemed to suit.

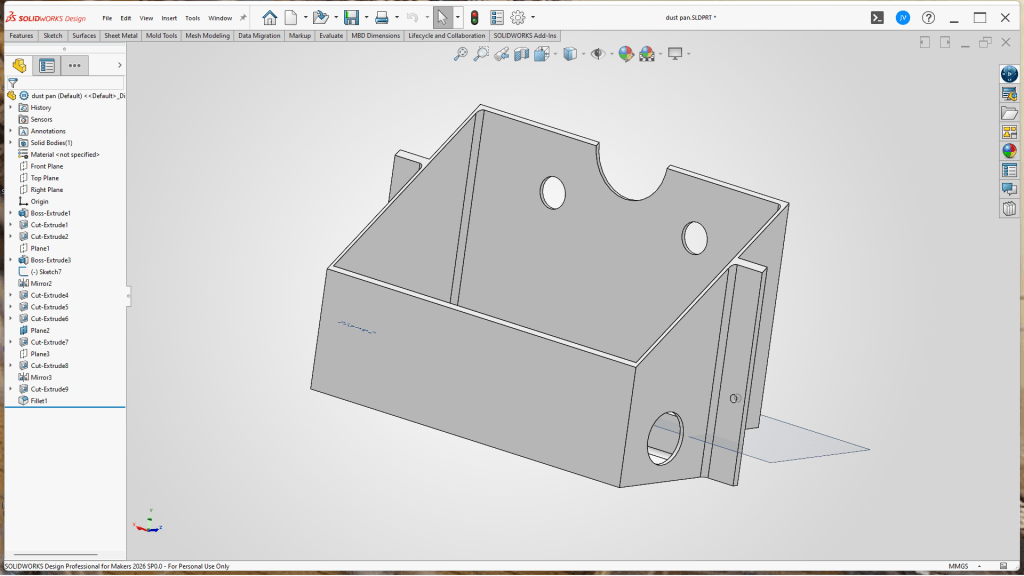

So, back to Solidworks and I ended up with this design….

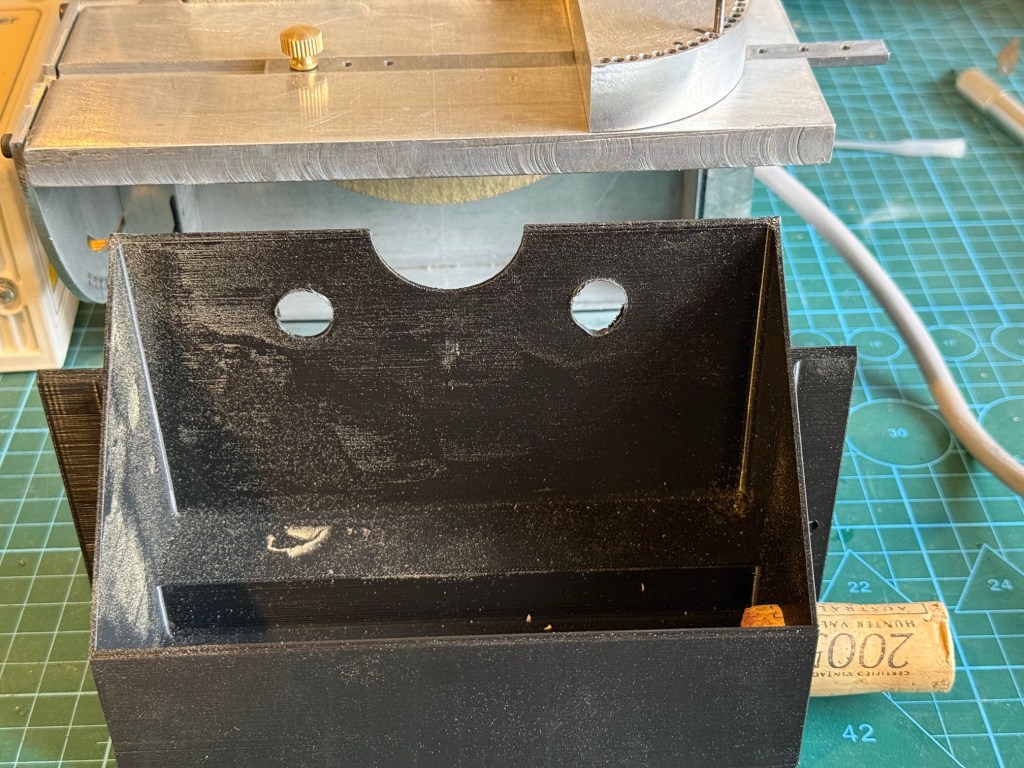

It looked a bit tricky and complicated to fabricate, so I 3D printed it. With my QIDI filament printer. The hole in the side it for the vacuum hose. Took 3.5 hours to print, but fitted perfectly.

The sander table is able to tilt to 45 degrees still. Do you like the temporary plug for the vacuum hose? It was a good vintage. And the tray comes out with a bit of wriggling.

p.s. A few days later I printed a lid for the dust box/vacuum attachment, to increase the air flow around the sanding disk. And used an old CPAP machine hose to connect to the box and the vacuum machine. The vacuum is one of those cheap Chinese rechargeable battery tools that is always on hand to my modelling desk. The lowest setting is the quietest and seems adequate. Cost in Oz about $aud20-30.

I think that my flow of bright ideas for this tool are starting to slow, but there are still one or two to go.