HMS Bellerophon model -2, and a bench saw on the way.

by John

I flagged this next project a few posts before I ran out of storage space on my WordPress johnsmachines.com site.

Since I have now created 1gB of storage space by deleting 2.5 years of posts and media 2014-2016 I am able to recommence posting current stuff. I have saved those posts on my own computer, but regrettably they are not able to be shared.

I plan to make the model ship from scratch, i.e. not using a kit or bought parts,as far as possible. However I will be using plans of HMS Vanguard, which was almost identical to Bellerophon, except for decorations, figurehead and name. Both ships had distinguished careers which I will address in a future post.

Bellerophon was a 3rd rate Ship of the Line. It had 74 guns, a crew of 550, and being a ship of the line was considered suitable for fleet actions, such as the Battle of the Nile and Trafalgar. It was a very effective battle ship, heavily armed, very strongly built, and reasonably fast. A frigate, even a heavy frigate such as Constitution, would probably have come off second best against a ship like Bellerophon. The 74’s were the commonest naval ship produced by Britain and Framce because of their effectiveness, and reasonable cost of building and operation.

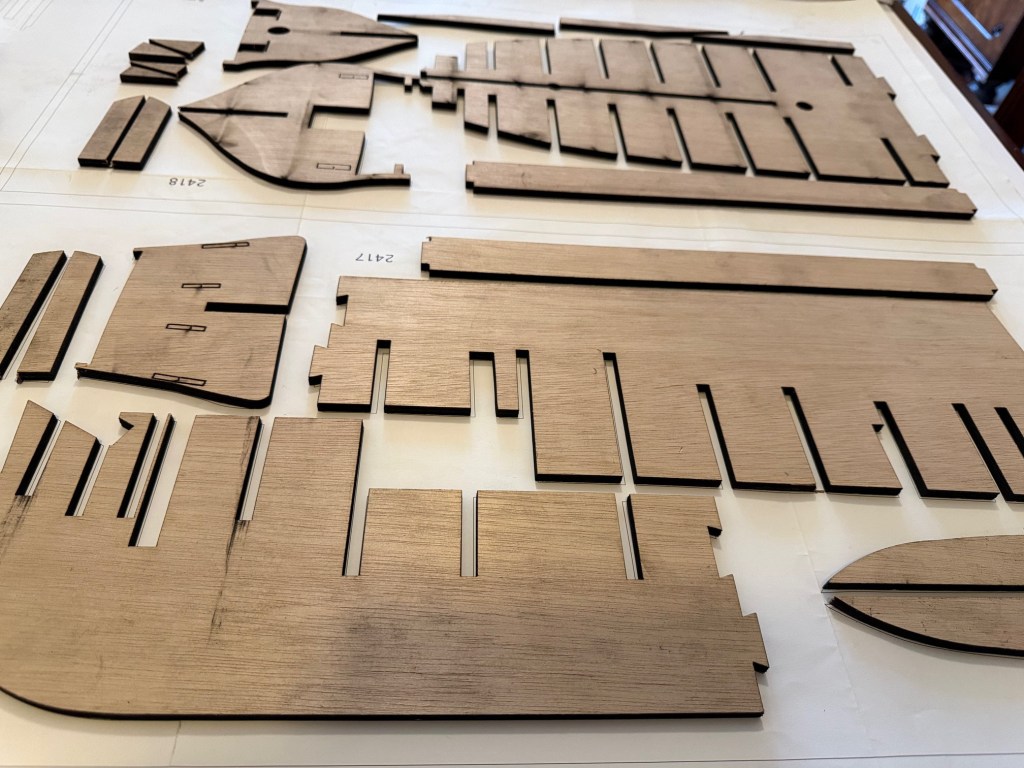

The plans were loaned to me by a friend who had built Vanguard. I had the plans scanned and copied, and decided to get the structural parts of the hull commercially cut using a laser. Unfortunately there was a complication.

The plans were centered around those structural parts being 5mm thick. Despite extensive searching I could find NO suppliers of reasonable quality 5mm plywood.

So I spent quite a few days modifying the plans to use 6mm plywood. That involved widening the slots to 6mm, and trying to forsee any consequences. Undoubtedly there will be unforeseen consequences, which I will detail as I progress. I did consider building an “Admiralty” style model but wanted a planked model, with masts, rigging etc, so settled for a bulkhead/keel type model.

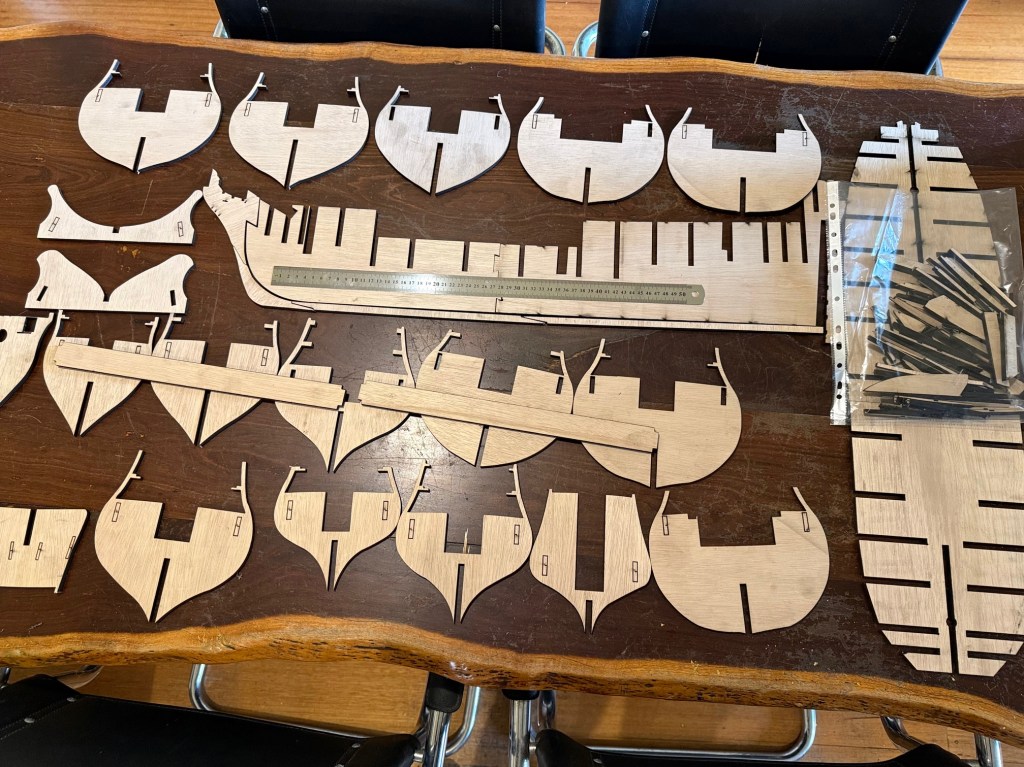

Then a few days ago I collected the laser cut parts from JR Laser, North Geelong.

The steel ruler is 500mm long which gives an indication of the model size.

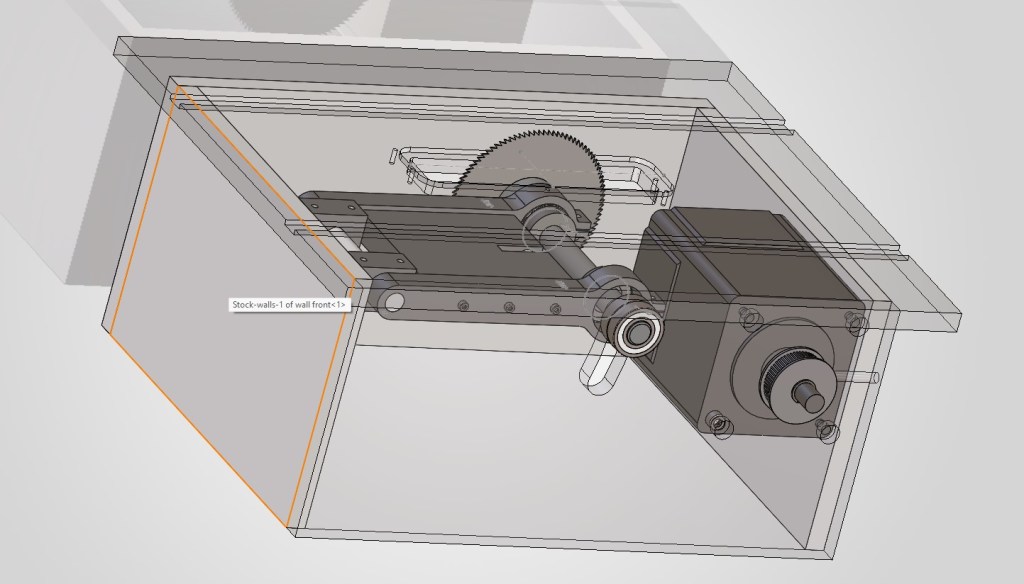

Also, I am currently building a Byrnes style bench saw. It is progressing well, but awaiting parts from OS. I am using some elements of the Byrnes saw, but have made the table longer, and situated the motor in the box instead of behind it. The box is made from 16mm thick alu, and the table is 12mm thick alu. The motor is a 750w AC servo, with speed and direction control.