In a recent post about 2 pressure gauges which I bought at a club auction, a reader (Daredesign) asked whether pressure gauges are able to be adjusted if the calibration is out.

One of our GSMEE members used to manufacture pressure gauges, so I asked him.

Frank and an artist made about one gauge per day. They were precision instruments, reading within 1:200 of the gauge reading. And priced accordingly. The face marks were painted by hand onto each gauge face by the artist, in positions marked by the instrument maker in a temperature controlled room.

Pressure gauges CAN be adjusted. And the better the quality of the instrument, the more readily it can be adjusted. The means of adjustment depends on the nature of the error.

If the error is a constant number throughout the pressure range, the pointer is removed from its tapered spindle and replaced in the new position.

If the error varies throughout the pressure range, the adjustment is of the inside mechanism. Two arms named the link and the quadrant are joined together and the join position and angle between the parts can be adjusted. The length of the link can also be adjusted. Frank gave me a detailed explanation of the types of errors and the adjustments, and I do not remember the details. I imagine that these procedures should be left to experts like Frank.

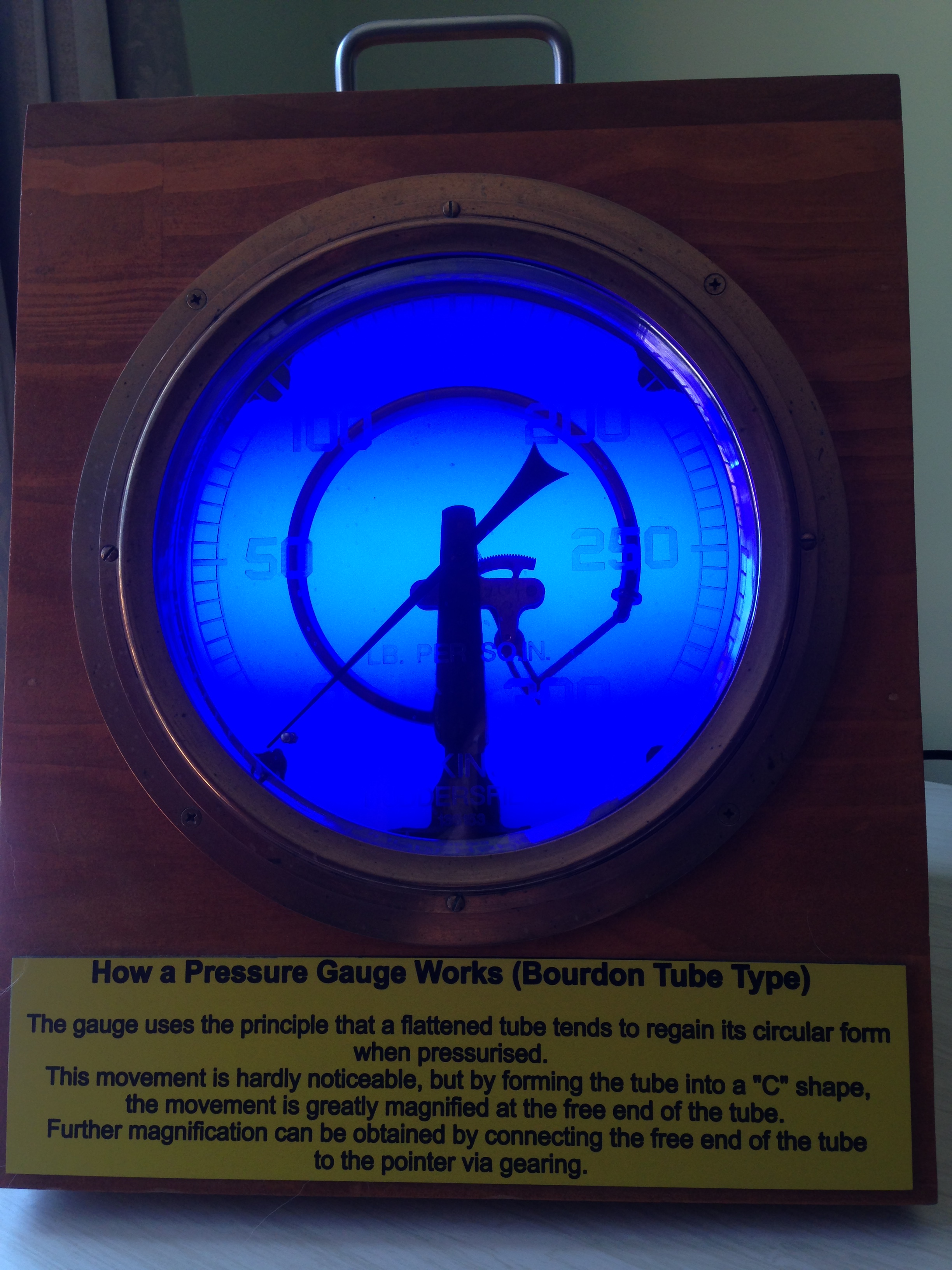

Frank also explained the workings of the Bourdon tube which is the main component of most pressure gauges. The Bourdon tube is a thin walled, oval section, copper-beryllium alloy tube, bent into an arc, and closed at one end. With pressure increase the tube tends to straighten, and the movement is translated into movement of the dial needle. The copper alloy is chosen because of a property called hysteresis, which I understand means that it returns exactly to its original shape when the pressure in the tube returns to its resting level.

In this diagram, the quadrant is named “sector”. The angle between the segment lever (or “quadrant”) and adjustable link should be 90 degrees when the pressure is halfway in its range.

So, I hope, Daredesign that this answers your question, and that I am reproducing the information accurately.