HMS Bellerophon. 1- Making Plans

I intend to make a model 74 gun ship, and I have decided to take a risk, and do a scratch build. i.e. to not make the 74 from a kit.

My first experience of using a wooden kit, was USS Constitution, from Mamoli. As a beginner, it was not the best choice. Many parts were not accurately cut. In fact they were obviously hand cut, with all of the inaccuracies that method entails. A later kit, for the Khufu pyramid ship, was much more accurate, and was a pleasure to assemble. It was laser cut.

And, as result of my own reading and “research”, I made various modifications to the Constitution plans. For example I made the ships boats from another supplier (Shicheng). And I made all of the model ropes instead of using those supplied.

For a first effort, the result was OK.

But there were mistakes, and misinterpretations of the instructions and plans.

The most satisfying parts of the build were the bits where I made parts from scratch.

So, my next build will be from scratch.

But, I want to work from plans.

So I have bought books (The Seventy Four Gun Ship by Jean Boudriot, Building The Wooden Fighting Ship by Doods and Moore, and quite a few other books); and plans (from Ancre, for an admiralty style hull, and HMS Vanguard from Victory Models).

Eventually I settled on the Victory Models plans. They are simpler and more suitable for my skill level, and will probably take a fraction of the time to complete vis a vis the Ancre/Boudriot plans. Even so, I expect that the build will take at least a year, despite my habit of working quickly.

The first step was to get the plans scanned, a copy printed, and electronic copies on my computer. I chose to have the printed copy on heavy duty paper, almost cardboard, so I could make cutout templates if required. That was not cheap. 20 x A1 prints plus the electronic pdf’s was $aud275. When I felt the weight of the printed versions, I felt better about the price. They are quite substantially heavy.

Then I decided to have the keel, bulkheads, decks etc laser cut. I do have a scroll saw, and considerable wood working experience, but the speed and accuracy of laser cutting was persuasive.

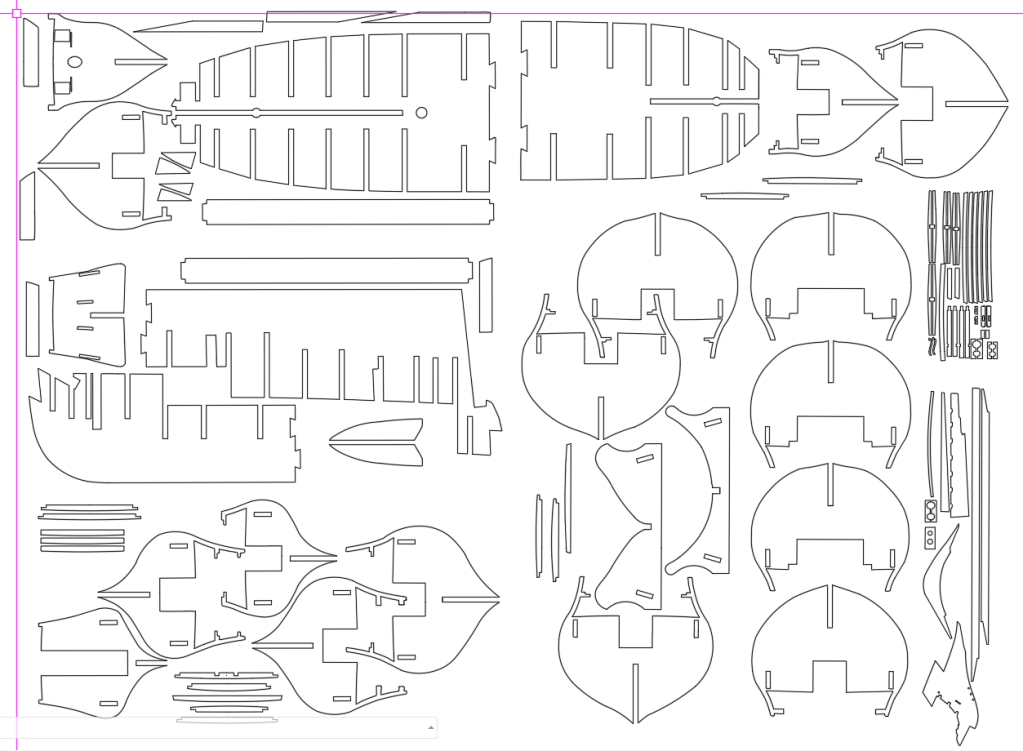

My electronic version of the Victory Models plans was in the form of pdf’s. The laser cutting service requires dxf’s. I do not have sophisticated software to convert pdf’s to dxf’s, but I do have a simple free program called “Print2Cad”.

So I converted one page of the plans as an experiment.

Print2cad processed the plan quickly, and I saved the converted plan as a dxf.

AutoCAD 2024 opened the dxf. (Hobbiest version of AutoCAD).

It opened normally and superficially looked good. But when I zoomed into the parts there were multiple problems. Many sharp corners had converted to arcs. And many straight lines were converted to arcs.

So I was committed to spending many hours to tidying up the converted dxf.

Then a bigger problem surfaced. The bulkheads, keel, decks and beams were to be cut from 5mm ply. The slots and joins were planned around 5mm ply. So off I went to my local ply supplier, calipers in hand, to measure the exact thickness of their ply. 3mm, 4.5mm, 6mm, no problem. BUT NO 5mm!!

I went home and searched the net for other suppliers. No-one supplies 5mm ply. Except some packaging ply is said to be 5mm, but it looked rough and knotty, and the one which I measured was actually 4.5mm anyway, and not very rigid.

I mulled over this for a week or two. Revisited the idea of making an admiralty model from solid wood. Wondered about changing the Victory Model plans to use 6mm ply. That was going to take a lot of hours, and no doubt there would be unintended consequences from the changes.

I did consider getting the laser cut pieces as planned for 5mm slots, and widening the slots to 6mm as required, one by one.

However, at this point of time, I have spent most of the past 3 days redrawing the plans to use 6mm marine ply, widening the slots, and fixing the unwanted arcs into straight lines.

I realise that there will be unintended consequences of these changes, and I have tried to anticipate them as far as possible. Since all of these plywood parts are buried out of sight, I should be able to cut and fill where necessary, and even remake parts totally. With wood, one can use glue to add extra wood, pack with chips/sawdust or builders bog, or chisel and saw unwanted bits. There is always a solution.

Meanwhile I am waiting for a cost estimate from the laser service. (JR Laser, North Geelong).

Incidentally, the plans are actually for HMS Vanguard. I am intending to make HMS Bellerophon, which was almost identical in all aspects, except for decorations, figurehead etc. Both were Ardent class, ships of the line, 3rd rates. They were heavily armed, strongly built, reasonably fast ships. Complement 550.