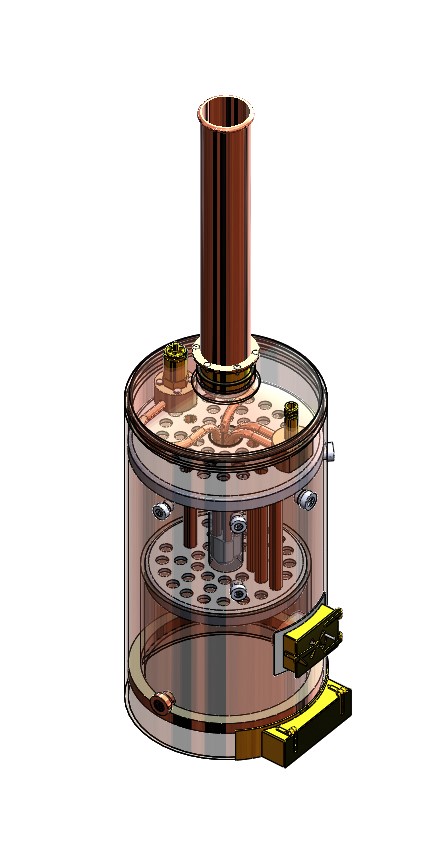

6″ Vertical Boiler- the Firehole

The firehole is the opening where coal is shovelled into the firebox. It is oval shaped, and is exposed to the boiler pressure. It is made from thick copper tube. Oval holes must be formed through the boiler wrapper and the firebox wrapper.

The elliptical hole in the boiler wrapper, and the firehole tube.

The first task is to shape copper tube which is circular, into oval shaped tube. I decided to make an oval shaped split wooden form and to compress the annealed copper tube with the form.

The wooden slab is cut into 2 pieces which are then cramped together, and the oval hole is CNC machined.

A 1″ 25mm length of 3.2mm thick walled tube is cut off, then annealed. Note that I have upgraded my forge. I bought some aerated concrete blocks (Hebel), and enlarged and encased the forge. The white Hebel blocks reflect the heat and the forge temperature rises quickly. the outside of the forge remains quite cool, testimony to Hebel’s insulating properties. Hebel is quite inexpensive. A 600 x 200 x 100mm blocks costs $AUD4.60. Heating time is 60 seconds, vs 90 seconds with the previous setup.

The wooden form and the unshaped thick walled copper tube.

After squeezing the annealed coper pipe in the form, using a 6″ vice. Nice elliptical shape. Note the pencil witness mark.

Then the elliptical hole is cut into the boiler wrapper. The vice jaws were replaced by temporary aluminium jaws 4″ high, adequate to hold the 6″ diameter tube. Cutting the elliptical hole on the CNC mill. There are wooden plugs in the boiler tube to prevent the boiler tube from distorting

The finished boiler hole and the elliptical insert. This was tense machining.

The fit is a bit too tight. I will take off another 0.1mm so it is an easy sliding fit, suitable for silver soldering. Then to cut the same elliptical hole in the firebox wrapper, but while the main cylinder is set up in this position I can cut openings for the ashpan and safety valve bush.