Khufu Ship – The Eye of Horus

This project is finished.

The model of the 4500 year old ship is made, painted, gilded.

CA and Gorilla glue used to hold the planks together, as specified in the Woody Joe Japanese kit, instead of the original rope and twine bound planks.

And I added some gold foil to the bow and stern pieces. I thought that I was adding actual gold gilding, but the AI revealed that “gold foil” is actually a copper and aluminium alloy. I did eventually buy some real gold leaf, but stripping off the foil and replacing it with real gold seemed too much so I am left with the foil, with and an artist grade varnish.

In the original Khufu pyramid ship there is some evidence of gold leaf being used, but hey, this is a model.

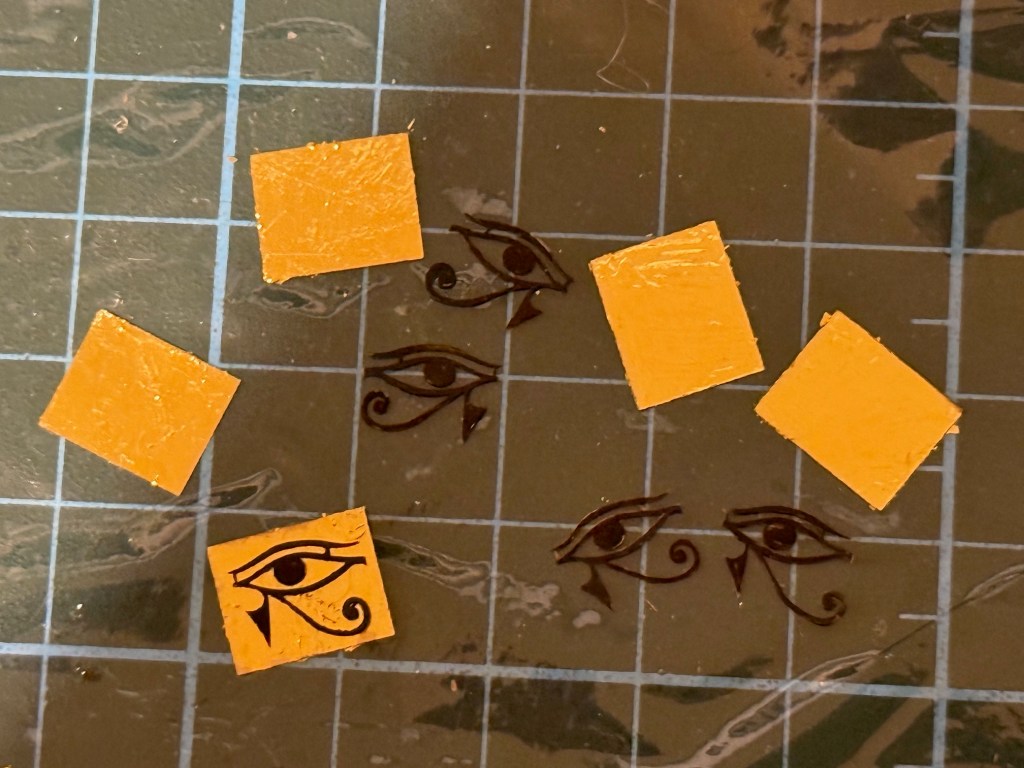

At the bow of the ship there was probably an “eye of Horus”. So I agonised how I was going to make and install that essential component. The kit maker offered an optional transfer, but I decided to make my own version. Fortunately Google Images had a nice pattern.

At a believable scale on the model ship, the “Eye” would measure 10x8mm overall. And the thickness of the black strokes is only 0.5mm thick. No way that I could paint that.

So off I went to my friend Stuart, who had fired up his 30watt fibre laser. And he lasered the 6 eyes from 0.2mm thick brass, in about 30 seconds! A bit of extra time adding fine bars so the eyebrows would not be lost. And some backing brass plates from the same 0.2mm brass shim, and I ended up with 5 good copies of the eyes, 2 left and 3 right.

I gold foil covered the backing plates, and painted them with artist grade varnish.

I painted the Eyes with black acrylic artist’s paint, and left all of the articles a day or two to dry and cure.

I glued the eyes to the foil coated backing plates with a fresh coat of the artists varnish, and left them to dry for a further day.

Then today 27 Dec, I glued the assembled Eyes of Horus to the bows of the starboard and port sides, using CA glue, after scoring the painted ship sides and back of the backing plates, with a sharp scalpel.

So. That model is finished as far as I am concerned. It has been interesting, and the model is quaintly intriguing. Not sure where it will end up. Maybe one of the grand children will become interested in Egyptology.