CNC Mini Mill-4

After 3D printing the structural components of the mini mill, I had to wait for postage arrival of the bearings, hardened steel shafts, trapezoidal screws and nuts, stepper motors, and various electronic components.

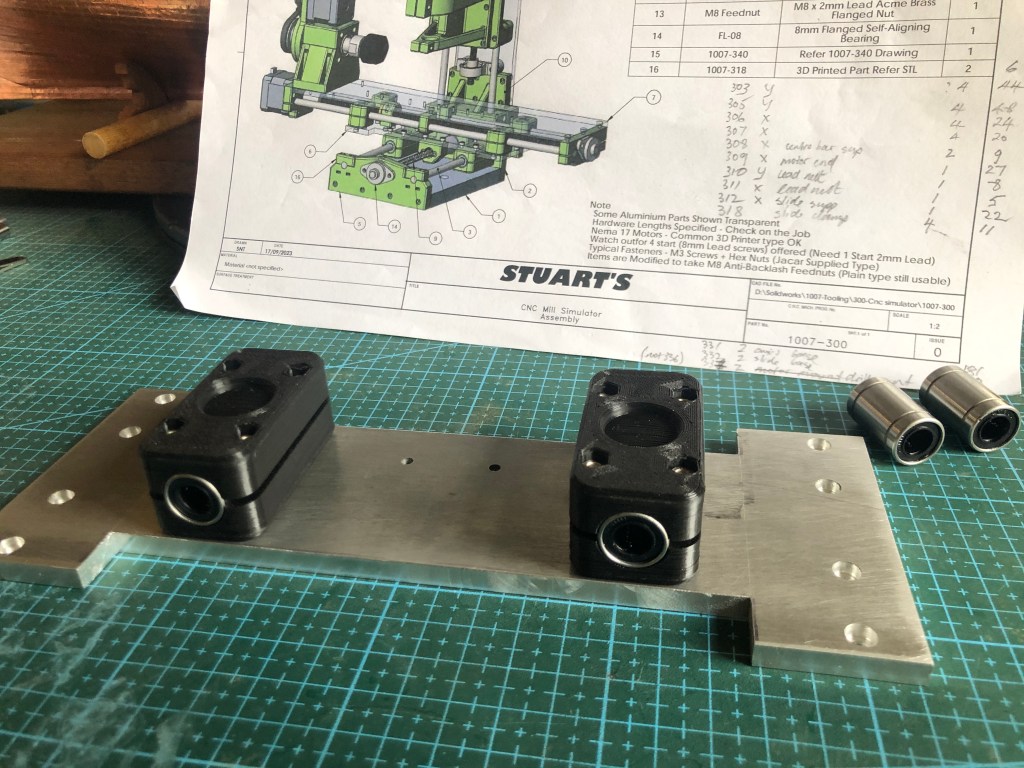

I used my bandsaw and my full size mill to make the aluminum X,Y and Z plates and the base.

Most components have now arrived, and I have been assembling them. Photos follow. Unfortunately the steel shafts were all bent, and are unusable. I don’t know if that is the way they were made, or whether it occurred in the post. A bit frustrating. The most expensive components have been the breakout out board, and the ESS. Altogether I have spent more than $AUD1000, about double what I expected. So I hope that the little mill will meet expectations.

Thinking about making the control box, but essential parts are yet to arrive. As you can see, it is taking shape.

….and Stuart T, has given permission for his plans and 3D printing files, the stl’s, to be published. I will do that when my build is completed. Not sure exactly how yet. I might need to get emails from interested viewers, and post them out directly. WATCH THIS SPACE.