Dahlgren Gun -1. A boring start.

Yesterday I made a start on the model 11” Dahlgren Cannon.

First I hunted around various suppliers for some steel round bar, 82mm or more diameter and at least 400mm long. Several suppliers had 90mm stock, but it was either too far for me to travel or gold plated.

Then, on suggestion from a GSMEE member I rang around the scrap metal dealers nearby. One thought that he might have something but it was only 75mm, but the next rang me back a day later and said that he had an 1800mm length of 82mm bar. Exact grade unknown, but “probably” mild steel. And it was less expensive than anyone else by far at $AUD1.50 per kg.

So I purchased it the next day. He put it onto my ute with a fork lift. $125 total. When I tried to unload it, I realised that I am not as strong as I thought. I did manage to roll it to the edge of the ute tray, and lever it off, jumping well clear just in time.

But when I attempted to drag it into the workshop I realised the difficulty, or impossibility if I am honest, of handling the 176lb / 80kg weight. So I used a 9″ angle grinder to cut off 400mm. Even that weighed 17kg. The remainder is still where it landed.

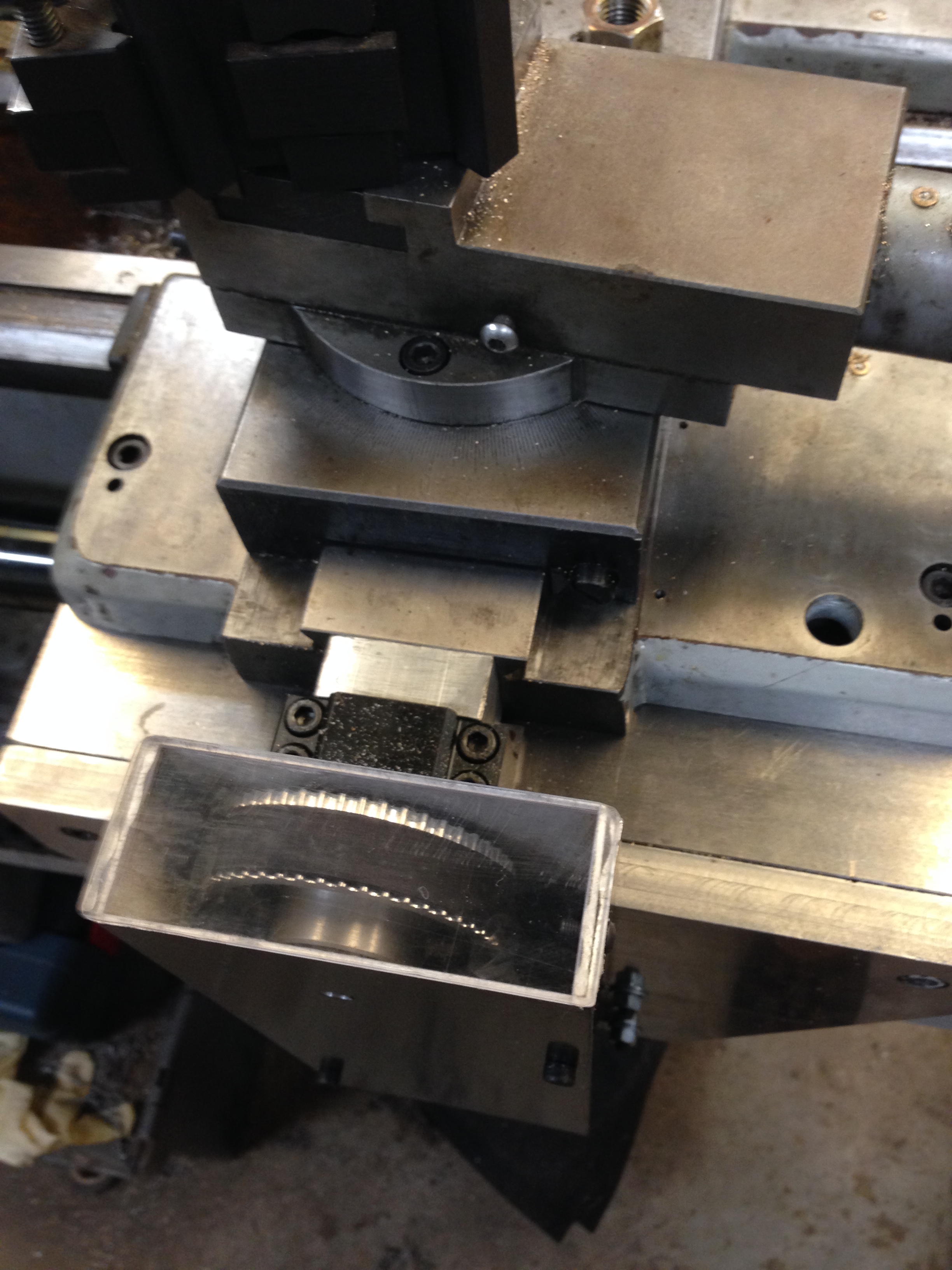

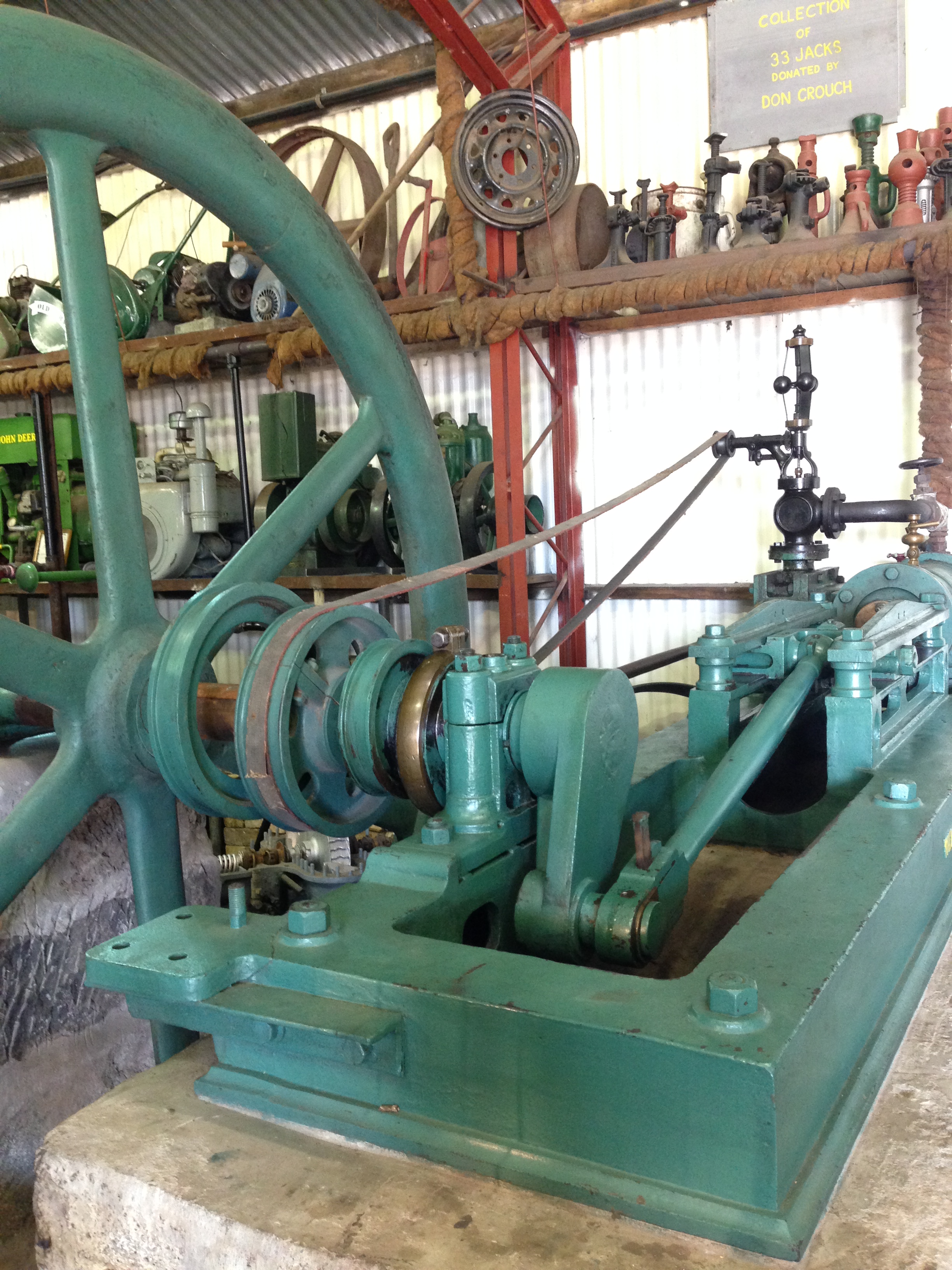

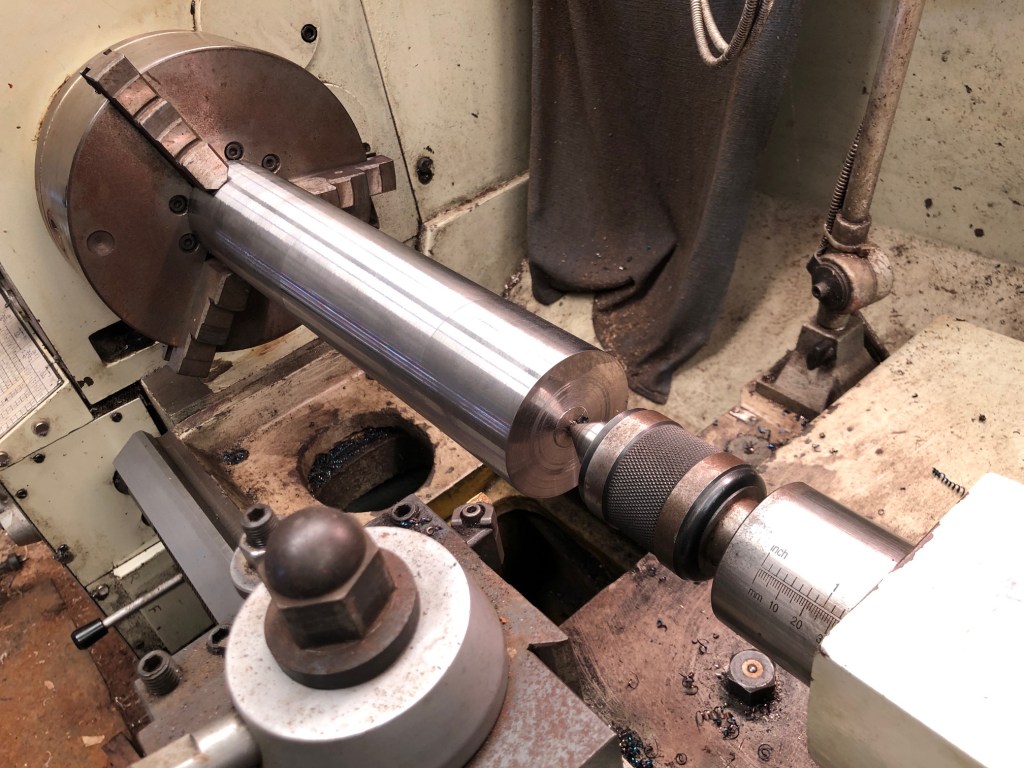

I was keen to see how the unknown grade of steel would machine, so marked and punched centres in the ends and mounted the heavy lump in a large 3 jaw chuck in my GBC 5hp lathe.

And rough turned the outside and end to just above the final diameter of 81.2mm. I had tested the hardness with a file, which just penetrated the surface, so it is pretty hard material. The first carbide insert hardly penetrated, so I used a new insert. That worked reasonably well, but I needed to keep up the cutting fluid, and use conservative feeds and speeds.

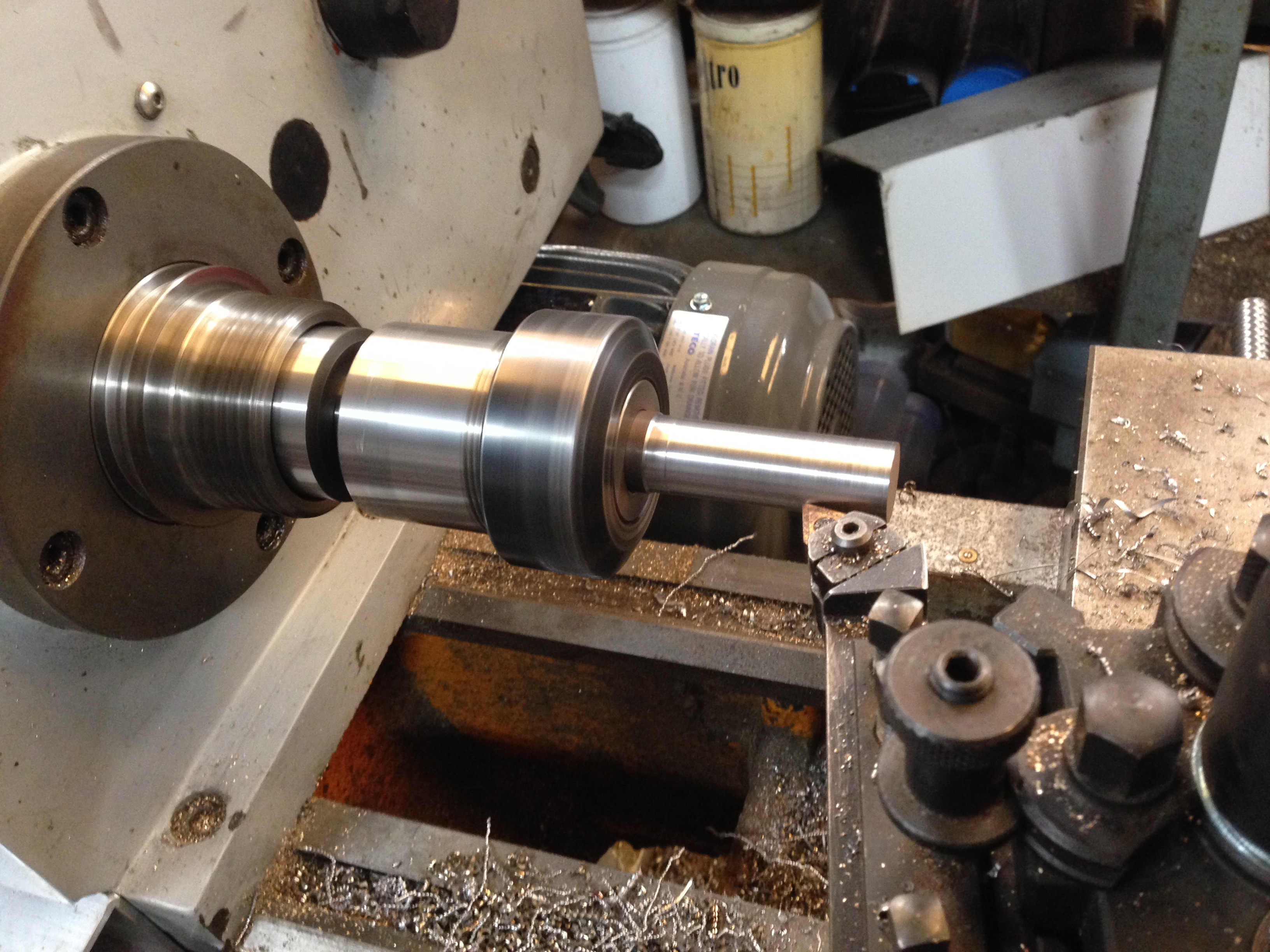

Then turned the workpiece end for end and finished the cleanup rough cuts. Then while it was still held in the 3 jaw, and the tailstock, I installed the fixed 3 point steady. Then removed the tailstock, and deepened the centering hole.

Using sharp drill bits I progressively drilled the first 100mm or so to 14mm diameter. Some pressure was required to make the drill bits bite, and I made sure to clear the swarf every 3-5mm of cutting, at the relatively slow rpm of 250.

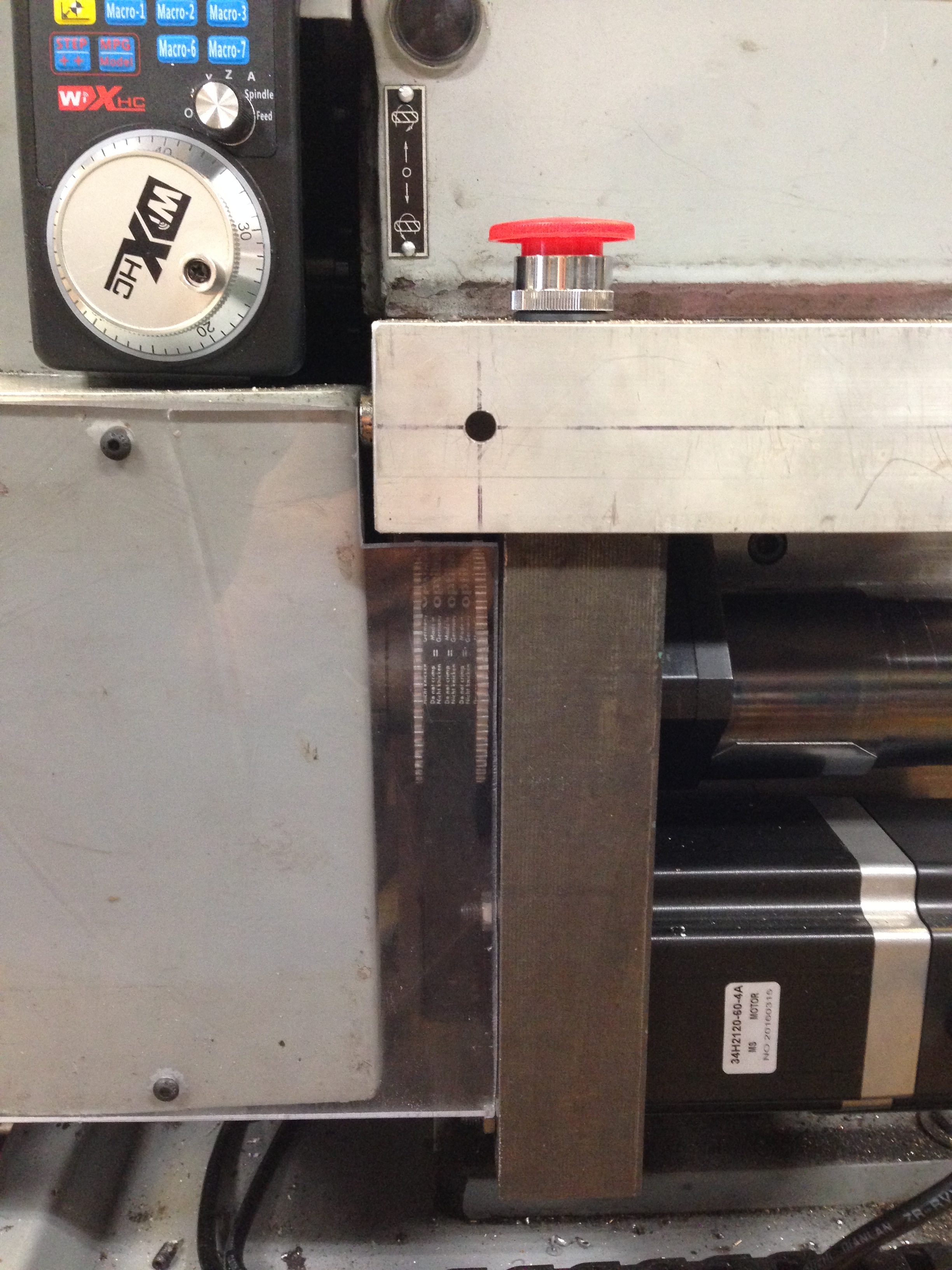

The lathe is Chinese, reasonably accurate, but rather noisy due to spur gears. It is a GBC 400-1000. Not my favourite lathe, but is the most powerful. (400mm swing, 1000mm between centers).

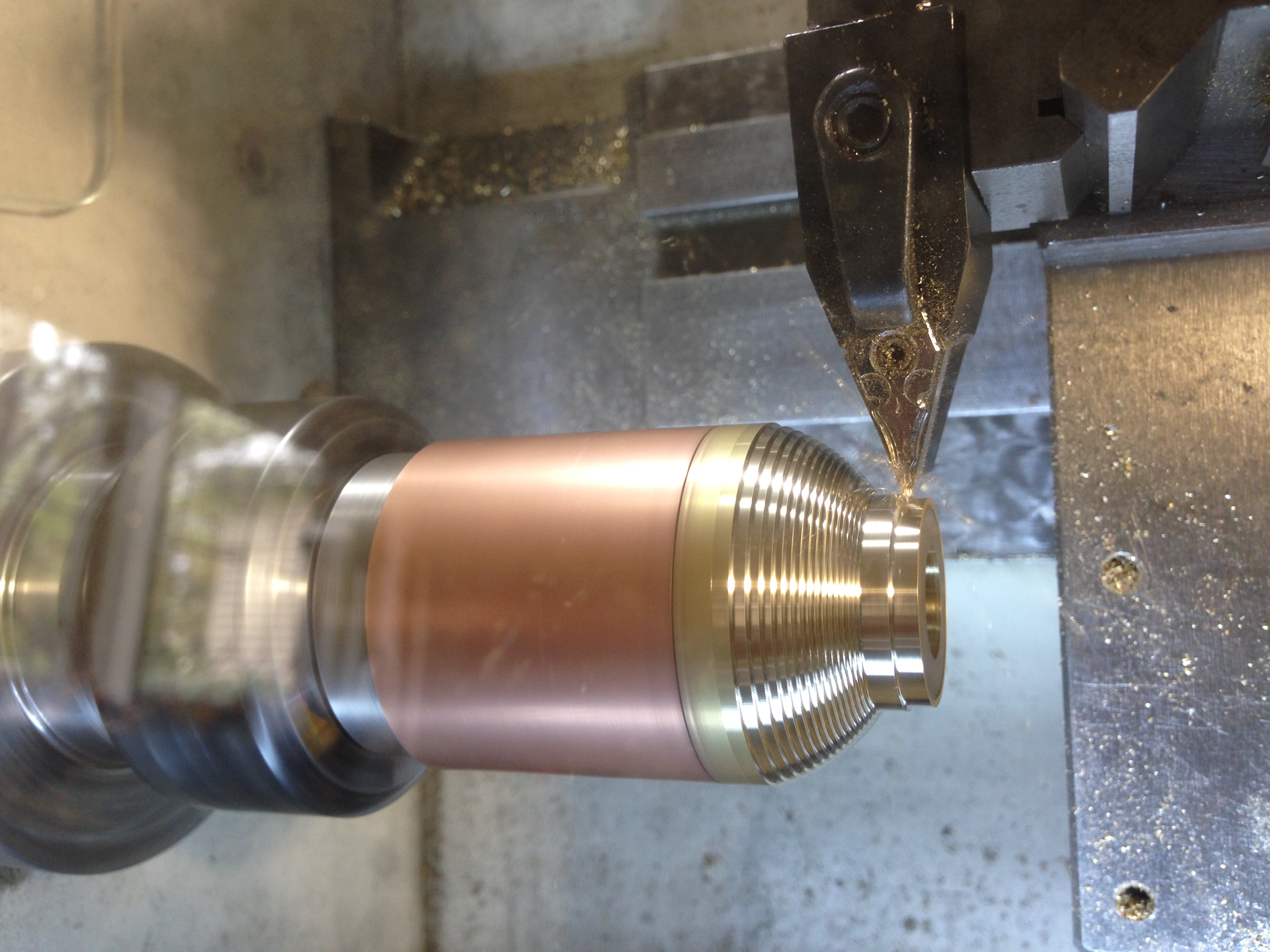

I am intending the bore to finish at 1.1”/ 28mm diameter (1:10 scale, smoothbore), and to drill from the muzzle right through the breech. The original SML Dahlgrens were cast iron guns, and the bore stopped well before the cascable, so my solution is not strictly kosher. But some smooth bore guns of the period (eg. Some of Armstrong’s) had screw in cascables, and it will be less difficult to make the model using that method, so that is what I aim to do. The final part of barrel boring will be threaded to accept a 1” /25.4mm threaded insert which will extend to become the cascable. That is the plan anyway. At least I have plenty of material to make another barrel if this one does not work out.

I used a 16mm good drill bit to progress the drilling closer to the breech. The drill bit was previously machined and silver soldered to a piece of silver steel drill rod, to extend it to 450mm long, for a previous build. (the Armstrong 80pr RML)

Clearly the swarf cannot be cleared continuously during drilling, so I back out the drill every 5mm or so, clear the swarf, and spray in copious coolant/lubricant. It is a slow process, but after an hour or so I am down to about 150mm/6”, and should break through in the next session if all goes well.

Enlarging the bore to 28mm will be a challenge, and so will cutting a 1” thread for the cascable.

So, Watch this space.

BTW, I have still not finally decided on the design for the carriage and slide. I would like to copy the ones at Patriot Point Museum (see previous post), but that will depend on whether I can source some accurate plans, or get permission from SWMBO to visit South Carolina.