Seizing/Serving Machine for Model Rope

First some terminology…

“Whipping” is winding a string or thin rope around a rope end to stop it from fraying. Not a nautical term as far as I know, except as a disciplinary measure, hopefully now not often used.

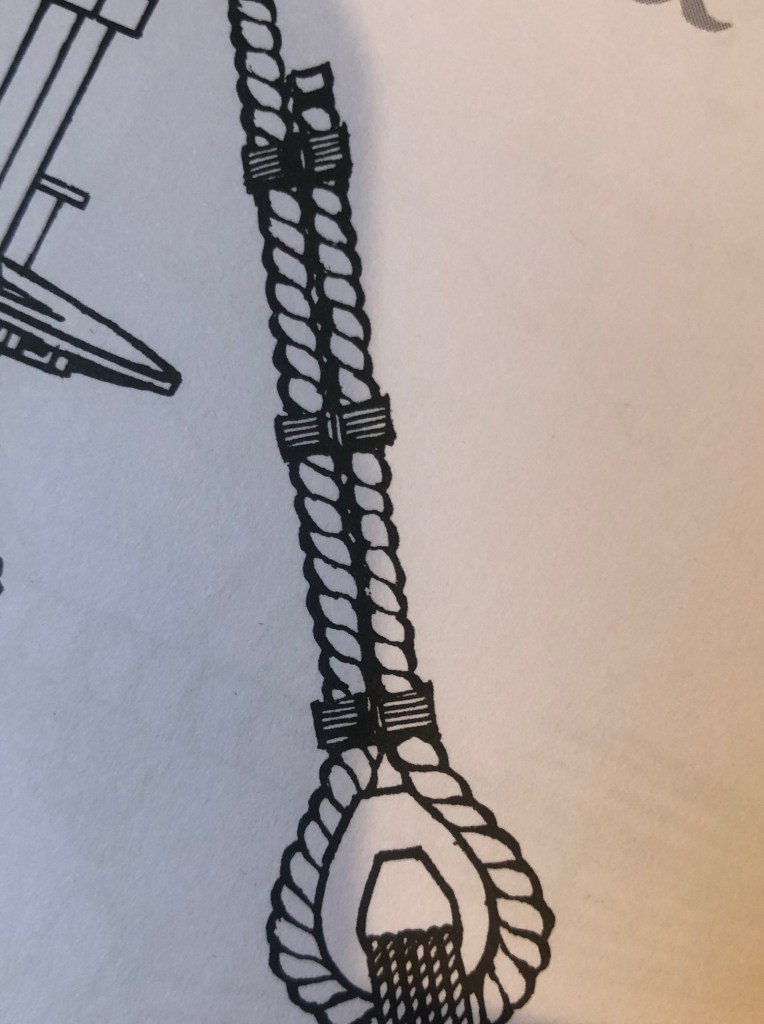

“Seizing” is securing a rope end which has been doubled back on itself often around a block, using string or thin rope.

“Serving” is covering a rope or shroud with string or thin rope to prevent chafing or rubbing wear, or preventing water entry into the rope. Sometimes over the entire length of the rope.

I am planning to make a machine to do the serving and seizing more neatly. The ropes to be seized or served on my 1:93 scale Constitution are mostly under 1mm diameter, so the thread used for seizing will be only 0.23mm diameter, or even thinner.

There are several machines available commercially, but, 1. I like to make my own machines and 2. I think that I can make a better machine.

I am considering 2 possibilities. Both involve holding lengths of rope (model rope), up to 400-500mm long, using ER collets. The rope is rotated at both ends, using a small electric motor. The serving thread (0.23mm dia) is moved along the rope, delivering one turn of serving per 0.25mm movement, of the main rope. It is a bit like making a thread in metal, which uses either gearing or CNC control. And that is the question which I am pondering. To use gears or CNC. Gears would be simpler, and fairly cheap. CNC would require input from my expert friend Stuart T, but would also be relatively inexpensive if I connect to the CNC output from my CNC lathe. CNC would also give me much finer control of the pitch of the serving/seizing. The gears method would be easier for other modelers/friends to use. I might end up by trying both methods.

So, watch this space.