3D Printed ER Collets. Really?

Remember the handle which I made for my CNC mill?

Well, it is installed, works well and I am happy with it.

However, the final job of drilling the 16mm hole for the centre shaft was not straightforward.

Because 1. That mill was out of action without the handle. Don’t ask. It just was. 2. I wanted to drill both holes for the handle without moving the setup in the milling vice.

So I drilled and tapped the 3/8″ thread for handle, no problems.

But when I came to drill the hole for the center shaft I realised that I had a problem. The only 16mm drill bit which I possess has a 3 morse taper shaft. I can use that drill bit in either of my two big lathes, or the mill which is out of action, or my drill press. But NOT in the CNC mill.

For the King Rich mill I have an NT40 to morse 3 (M3) adapter, but it has an imperial thread. OK for the mill which is out of action, but a real hassle fit to the CNC mill.

So I did the unforgivable. I drilled the handle hole out to 15mm with straight shank drill bits. Then fitted the M3 shaft 16mm drill bit in an ordinary 14mm ER40 collet. And drilled the 16mm hole quite successfully. The tapered drill shaft centered well in the morse tapered collet, and the drill cutting tip centered quite nicely in the 15mm hole. But it was brutal abuse of the steel collet.

So the handle was finished and fitted, but I did feel bad about the criminality of abusing the 14mm collet.

When I was on ebay later that day I tried to find a an ER40 collet with an M3 centre. Couldn’t find one anywhere. I am sure that there are NT40 tool holders for M3 drills and reamers but I did not have one on site with the correct thread.

Then the light bulb in my brain switched on!

MAKE ONE!! 3D PRINT IT!

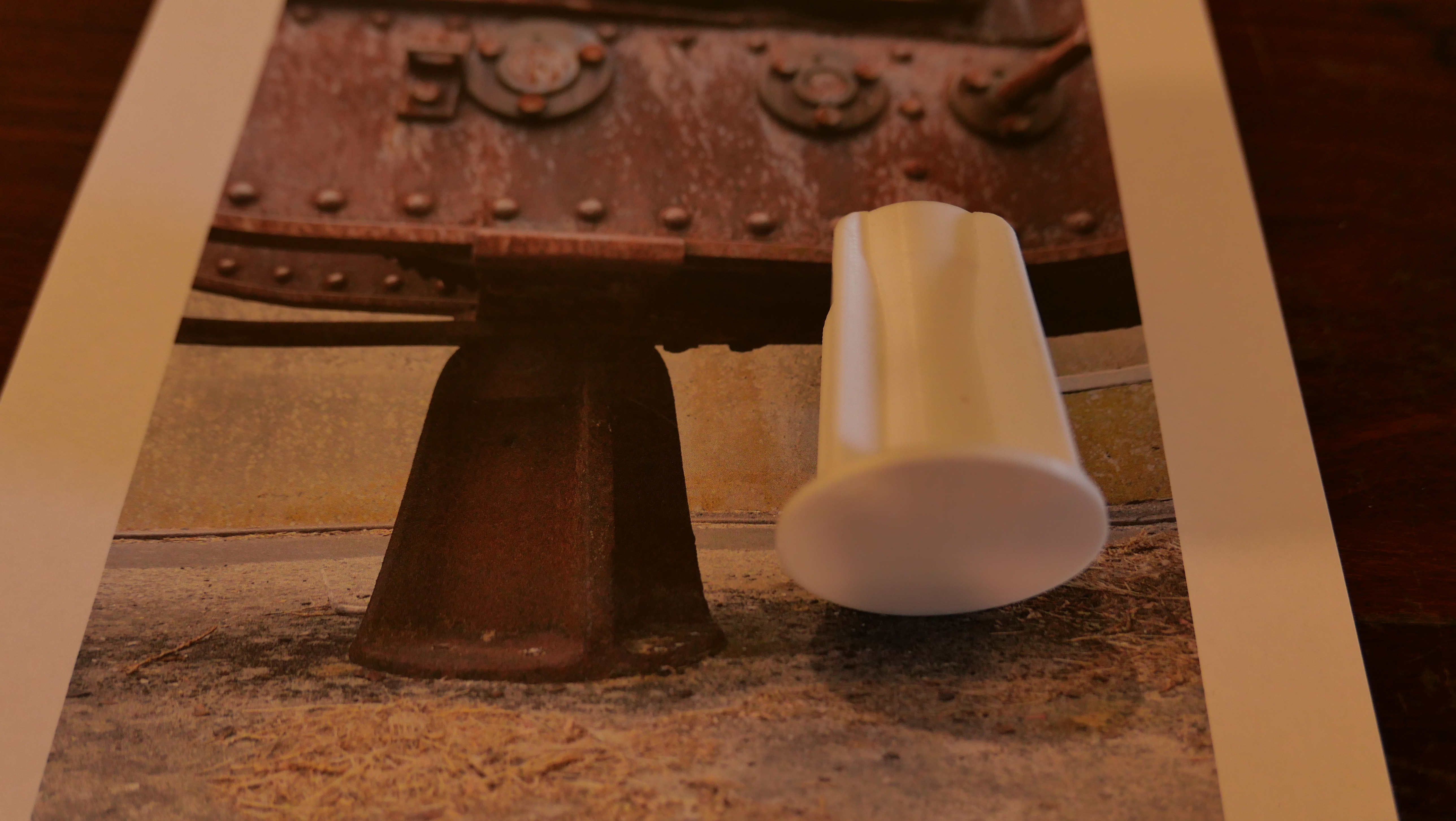

So I did. Actually it is an ER40 collet, with an M3 internal taper. Drew it up in Solidworks,

printed it. But the print FAILED. The small footprint in contact with the build plate (FDM printer) repeatedly broke free. SO I added internal and external brims. Print worked, but overhangs required supports.

PLA is a tough plastic with almost no compressibility. This ER40-M3 collet has 25% infill. I used 100% infill for later versions. Even with the 25% infill , the collet shows no signs of collapsing.

Early collets were printed like the one on the right… with the largest end on the build plate. But the supports made the surface rough where the collet nut presses on the collet, so later collets were printed in the position of the one on the left, where the rough surface matters less. It stayed attached to the build plate with internal and external brims.

The important fact, is that these printed collets actually function. Steel collets are preferred of course, but the advantage of these printed ones is that odd shapes, (like morse tools), can be held.

I have not yet conducted accuracy tests but will do so. Even if the printed collets are less accurate than steel ones (which is probable), they will have a place in my workshop.

I intend to design and make printed ER collets for other ER sizes and M2 and M1 drills and reamers. The method could also work for odd shaped workpieces, such as rectangular materials, non standard sizes. Watch this space! I will post some stl’s on Thingiverse soon, when I have tested them “in action”.

(printing time 2hrs per collet. 30g filament per collet. QIDI X-max 3 printer, Rapido PLA filament, “strong” setting,

P.S. 2 weeks later. I do occasionally re-read my old posts, and I sometimes think of extra aspects which I should have mentioned. This time I find myself wondering if I should have made the replacement mill X axis handle by 3D printing it. That would have been quicker, cheaper, lighter, probably function just as well, and have a built in ability to give or even collapse if I am stupid enough to cause the mill tables to collide again. And I reckon that it would be adequately strong to function as a mill X axis handle. Hmm……