Rigging the Constitution. Making Beckets.

Clumsy fat fingers. Poor binocular vision. Impatience. That’s me.

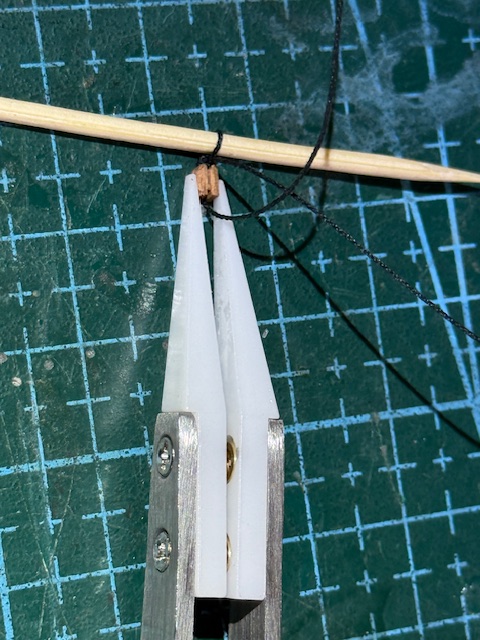

So attaching a block 3mm long to 0.25mm black thread, AND forming a Becket (a Becket, not Thomas), is a challenge.

I won’t say that I have developed the ideal method, but I have a method of sorts.

First, this is a block (a rigging pulley on a ship) with an loop at one end, and the other end is fastened to a mast or spar or standing rigging cable.

It is now ready to be installed on the model.

This post is almost certainly of no interest to anyone, except possibly me, so I can refer to it next time I have to make beckets from thread. An alternative method is to use copper wire and that is much easier, but not appropriate in this position. the black mark on the spar is a penciled guide line which I must remember to rub out.

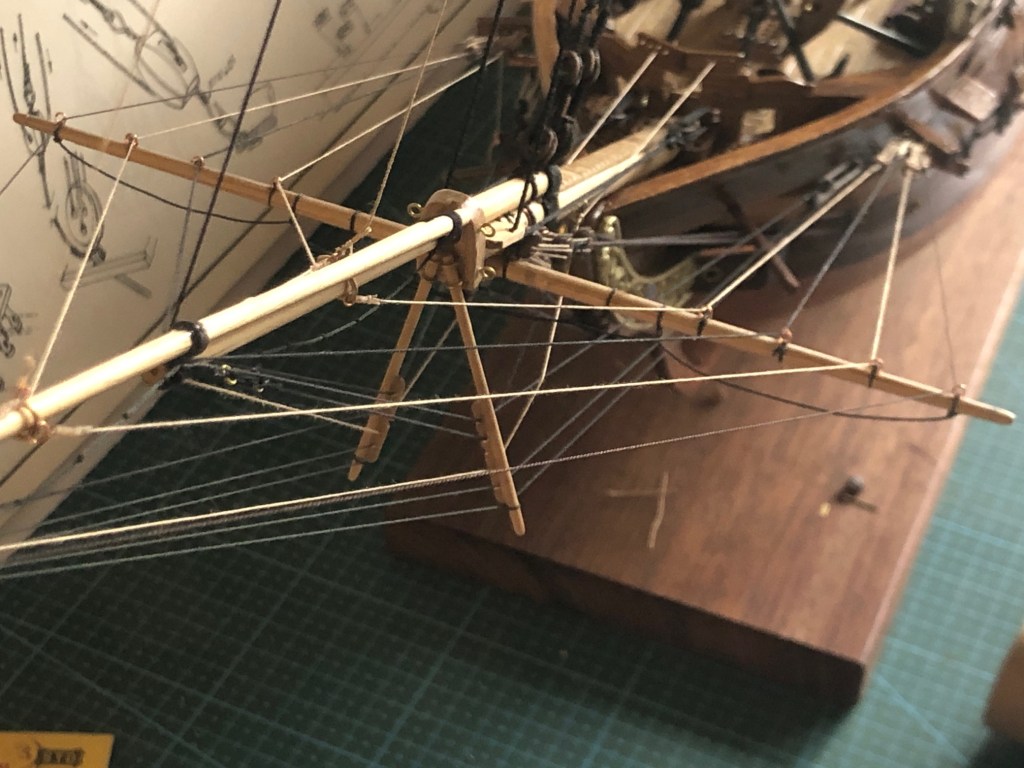

I have spent the last 2 weeks rigging the foremast of the Constitution. It, the foremast rigging, is close to finished. Then the mainmast and mizzen to go. When I say 2 weeks, I mean 5-6 hours every day, at least 5 days per week. So I will be glad when it is finished. I think that this model is pushing the limits of my patience.

However, I received a mail reminder from my optician for an eyesight check, which I had 2 days ago. It seems that the sight in my left eye has deteriorated significantly in the last 2 years, and that apparently explains my struggling with binocular vision. I am looking forward to some new glasses in the hope that will improve my rigging of the Constitution. I asked why my left eye has deteriorated. “75 years old” was the answer. Amazingly my right eye, which experienced the retinal detachment and cataract 9 years ago, is now 20/20.