Tailstock for the Rotary Axis – Mini Mill-10

OK, I know that I said the CNC mini mill was finished , completed etc. etc. but I still wanted a tailstock for the rotary axis.

I thought that Stuart’s design for the rotary axis could be modified to form the tailstock. But I do not have the software to modify his drawings or to modify the stl files used by the 3D printer.

So I spoke to Stuart and was very pleased when he offered to make the adjustments. I was delighted when the new stl’s arrived a couple of hours later. The parts took 4 hours to print, and another hour or so to fit the bearings, ER16 chuck and shaft, and the base plate to fit the T slots.

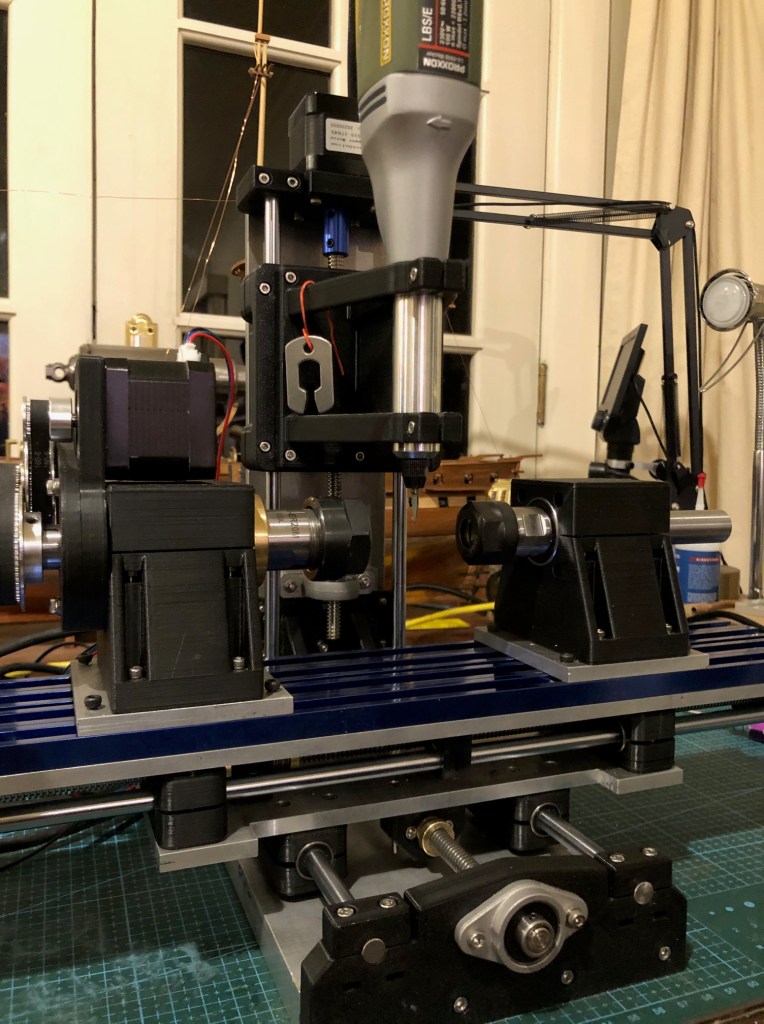

Rotary axis left, tailstock right, spindle with a small carbide cutter center. And the usual work-desk clutter everywhere else.

The CNC mini mill is now ready to be used. But I do have a further modification in mind. The X axis screw was a bit too long and I installed a small hand-wheel on the protrusion. The handwheel has been so useful that I intend to install slightly longer screws on the Y and Z axes, and to install handwheels on them too.