Just how strong is a silver soldered join?

I bought some 6mm x 0.7mm brass strip to hold on wooden lagging on my 6″ vertical boiler. Trouble was that I could find suppliers who had the strips only in 300mm (12″) lengths. So I decided to join 2 of the strips to provide the 450mm lengths that I need.

I have made band saw blades with silver solder, quite succesfully, but the ends were scarfed so the join was over a 5mm or so length of the blade.

I wondered whether I could butt join the brass strips with silver solder, and if so, whether the join would be adequately strong.

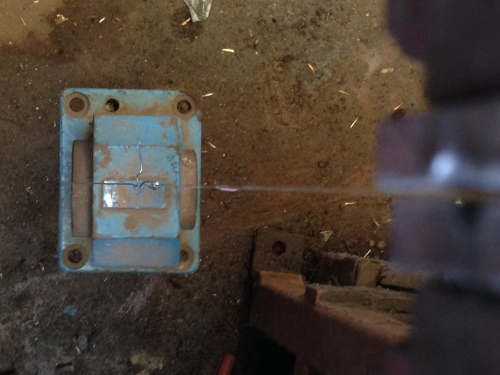

So here are the brass strips end to end, fluxed and weighed down so they do not move.

And here is the silver soldered join. Not particularly neat, but OK for the purposes of the test.

The other side. As I said, not particularly neat. And I did not even bother with an acid soak.

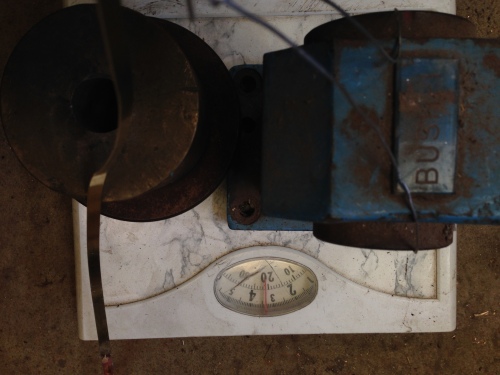

So I drilled a hole in the end of the joined strips, and wired on a hefty weight. The top end was held in the vise. Seemed OK so I increased the weights.

Looking down the strip from the vise.

By this stage I was standing back, expecting the soldered join to give way. But it did not. Hmm. Must do a tidy up soon.

21 kg, 46.3lbs.

At this point I stopped adding weights. I think that the soldered join should hold the wooden strips to my model boiler!

Are you impressed? I am.