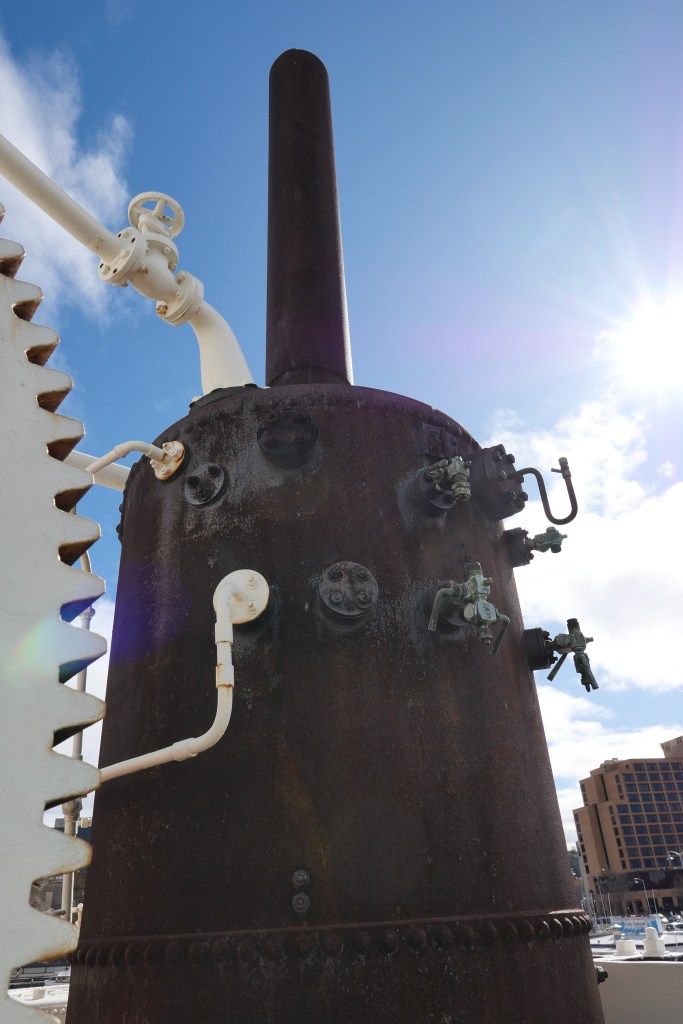

1899 Steam Powered Jessop and Appleby Crane

Swen Pettig (secretary of GSMEE) and I flew to Hobart 2 weeks ago to inspect, measure, and photograph the Jessop and Appleby crane at Constitution Dock, Hobart. We had become interested in the crane when plans for a 1:12.7 scale model appeared on Model Engineering Website. The plans were expertly drawn up by Julius deWaal, using information, photographs and some original drawings which were supplied to him by Tony Sprent AM, who lives in Hobart. More about Tony later. We contacted Tony, and he arranged with the authorities that we could clamber all over to get the information that we needed. We could have just used the deWaal plans to make the model, but there were some aspects, particularly regarding the boiler, that we wanted to check.

Firstly some photos of the crane….I took almost 200 shots, here are a few.

Swen has started on his model. Tony Sprent is well into his. I am yet to start.

Tony has had an interesting career. In brief, he studied physics and geology at university, then surveying and worked as a surveyor in Tasmania. Later he achieved a PhD, after researching and pioneering the use of lasers in surveying. This was back in the 1970’s (I think). He was awarded an AM for his volunteer work, amongst other things, inventing and designing mechanical appliances for disabled people, over many years. Now well into his 80’s Tony is still very active, constantly learning, designing, and making things. He is fairly computer capable, but he prefers a drawing board to CAD, and his lathe and mill are manual, although he is happy to utilise his machine DRO’s. It was an absolute pleasure to meet Tony, and we will continue to communicate with him. Who knows? We might even be able to entice him to the mainland to give our society a talk..