Another Use for Magnets

I purchased some bronze disks for use in the model Trevithick dredger engine. The disks 204mm diameter had been bandsawn off rod. I had specified minimum thicknesses of 7mm and 12mm. One disk was 9.2-9.7mm thick and the other was 12-15mm thick.

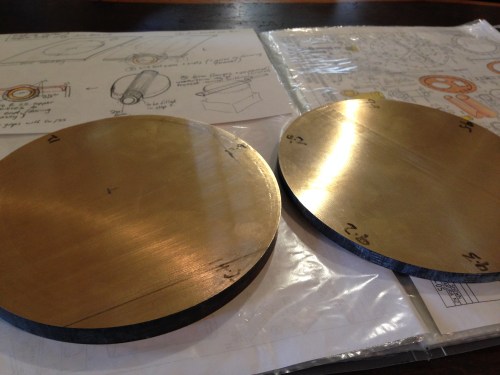

The bandsawn blanks of LG2 bronze.

In preparing the disks for machining I filed off a few protrusions, and using a straight edge, identified the valleys and ridges.

The thicker disk was held in the 3 jaw chuck and both faces were turned flat with no problems except avoiding the needles which were thrown off in a wide arc around my lathe. Final thickness 12.5mm. A persisting divot should be able to be avoided in the final part.

The thinner disk needed to be packed out from the jaws of the chuck by 4-5mm in order that the lathe tool cleared the jaws during machining. In the past I have used machined packing pieces, but it is always a fiddle to hold the workpiece, the 3 packing pieces and the chuck key in only 2 hands. Today I had a brainwave.

I used rare earth magnets!

I tried to measure the thickness of the magnets, but they are so powerful that I was not confident that I was getting accurate readings. So I just used them and measured the thickness of the finished workpiece.

I am sure that this idea is not original. But it is to me.

Here is the thin workpiece held in the 3 jaw, and packed away from the chuck by rare earth magnets. Of course the magnets are attracted only to the jaws, and not the bronze workpiece, which helps, but I will try this on steel later. Should work for magnetic metals also.

After machining both faces I took various measurments of the workpiece thickness. The measurements in mm were 8.73, 8.68, 8.69, 8.72, 8.70, 8.72. Not perfect, but not too bad at all. I wonder if I might have improved the measurements by surface grinding the magnets. I wonder if the chuck and its jaws are contributing to the variation. It was certainly an easy method.

If the workpiece had been thinner I could have increased the thickness of the packing by doubling up the magnets.

For those who are following the Trevithick Dedger Engine build, the bronze was not cheap. The 12-15mm disk was $AUD90 and the 9mm disk was about $AUD80. From George White P/L, Melbourne. I will be nervously trying to not muck up the machining.