Trevithick Dredger. A start on the Engine.

Some photos of progress on the Trevithick Dredger engine. I am still making components for the engine, which is a single cylinder, double acting steam engine. The valves and throttle are cylindrical, which is the method used by Trevithick over 200 years ago.

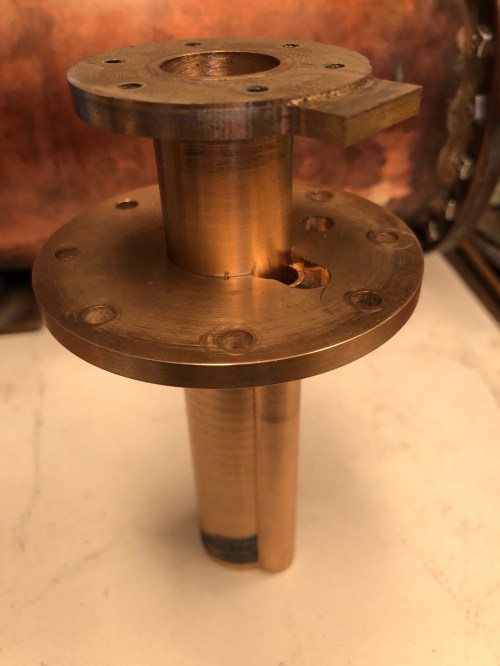

From the left… the cylinder, with rectangular steam ports and bottom cap; flanges; steam tube. The steam tube was bronze rod which was OD turned, then drilled, then split longitudinally, then bevelled so that it fits snugly to the outside of the cylinder. Tricky machining, done with a steel plug to avoid squashing the part in the milling vise. Some of the 5mm holes in the large flange should have been threaded. Error in the plans. Now considering whether to remake the flange or thread the holes 6mm and make some stainless steel stepped studs. Probably the studs…

Components pressed together. Later they will be silver soldered.

The valve chest was made from a chunk of bronze, which was first squared up…

Then marked out..

After preliminary drilling and reaming, the block was sawn to produce the truncated cylindrical hole. (any better suggestions to describe the shape?)

The steam chest will contain the cylindrical valves for throttle and steam opening-closing and direction. A complex item. Quite a few hours of nutting out and machining. Not quite finished.