Vertical Southworth Pump

by John

I will post progress in making this 6″ pump. I started making it 4-5 years ago, but put it aside when the horizontal version worked so well. See the previous post to see a video of the horizontal 2 cylinder pump filling the 6″ vertical boiler.

So, 2 workshop sessions later, and I have made the piston rod with steam and water pistons, and the studs which support the steam and water cylinders.

Doesn’t sound like much, for 2 whole sessions of 4-6 hours each, does it? But there it is.

First the studs.

They have to be identical lengths, with an M3 thread at each end. And a central narrower section with a curved end fillets. I decided to CNC the central section, with an Unbrako stud held in an ER collet (left) and a cap screw (right) in the tailstock.

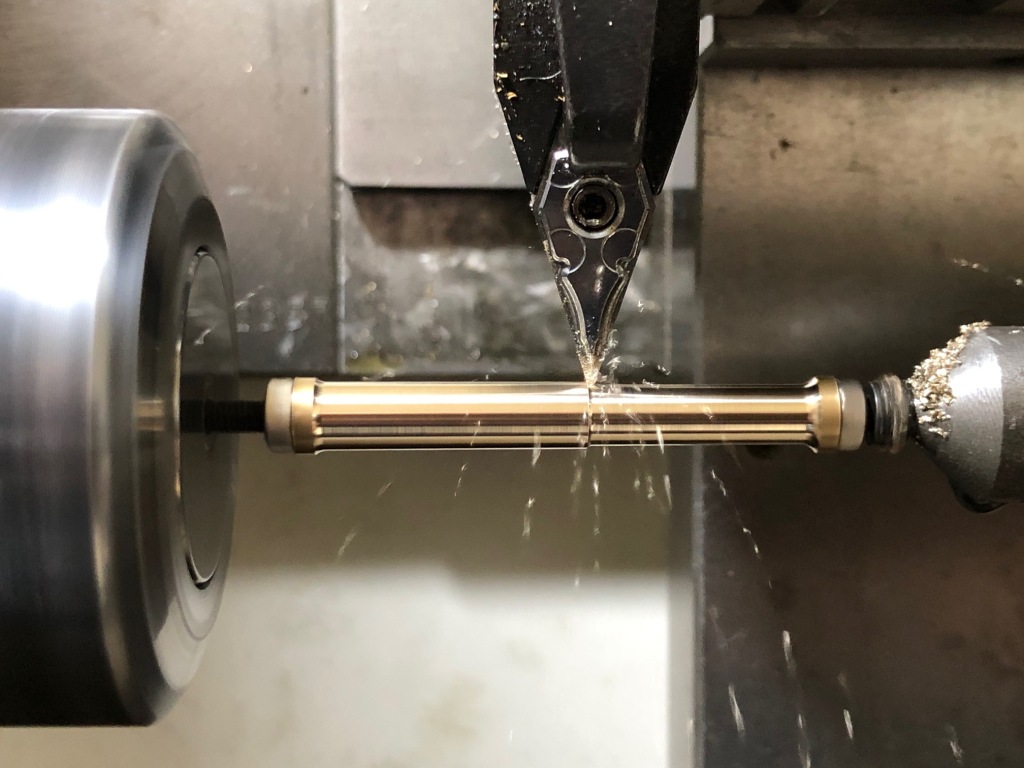

Then the single piston rod, 4mm diameter, with the large steam piston, and small water piston.

The grooves for the O rings were made with a parting tool. Depth determined from a “Machinerys Handbook” table, and the width 50% larger, as specified. Unfortunately I damaged the O rings during insertion into the cylinders. But I had some Viton spares, and filled the sharp edges of the cylinder bores before trying them, with better success.

That’s progress in my book John, and that’s a really nice shorter term project. I’ll be following with interest for one.

LikeLike