Mini CNC Milling Machine -3

by John

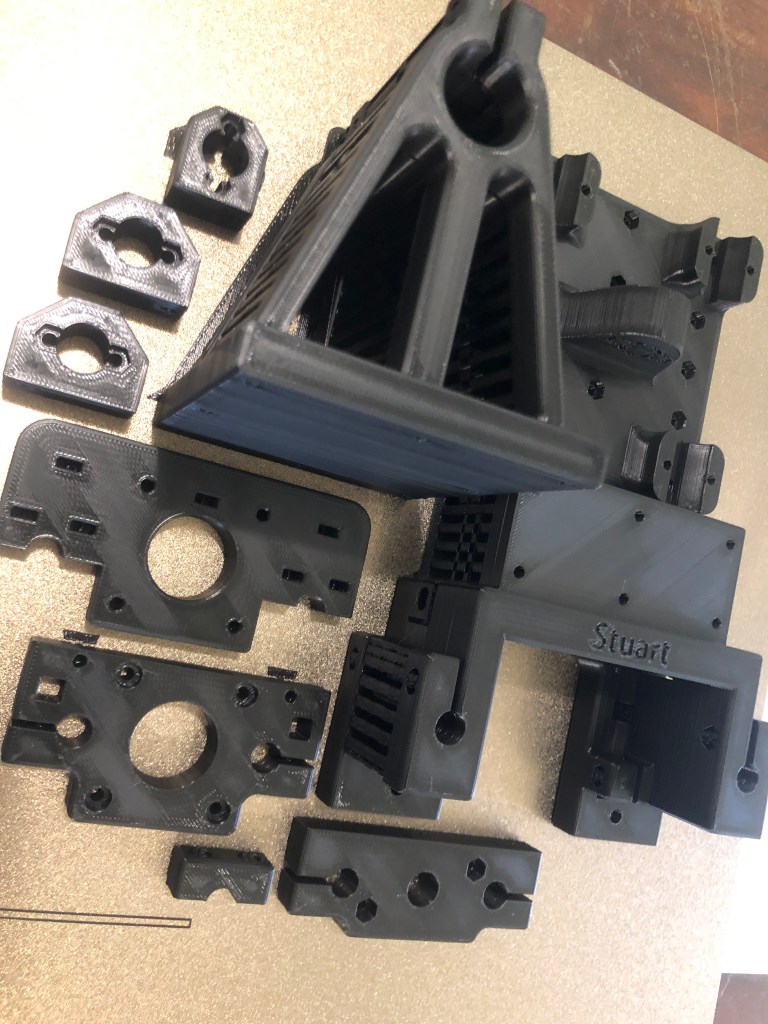

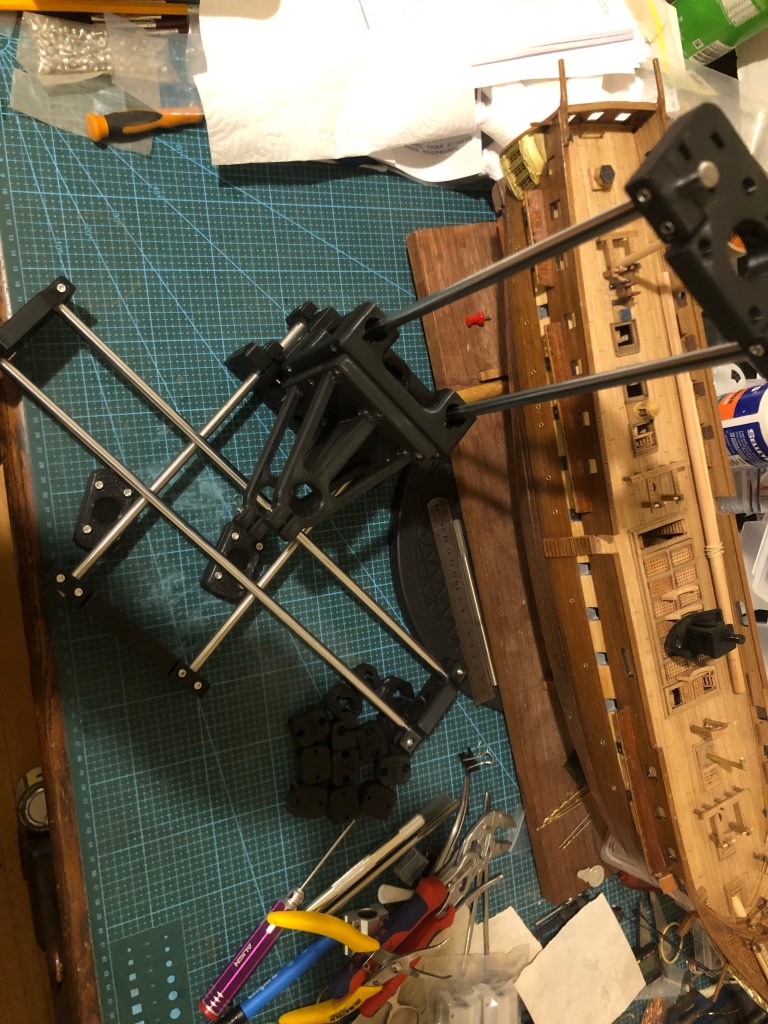

3 Sessions of 3D printing and the PLA printed parts are made. The first session was 5 hours, the second session was 15 hours overnight, and the third session was 8 hours. 28 hours altogether. And all of the parts look excellent and have a very solid feel.

Now I have to wait, impatiently, for bearings, stepper motors, trapezoidal threads and nuts, and other hardware to arrive by post.

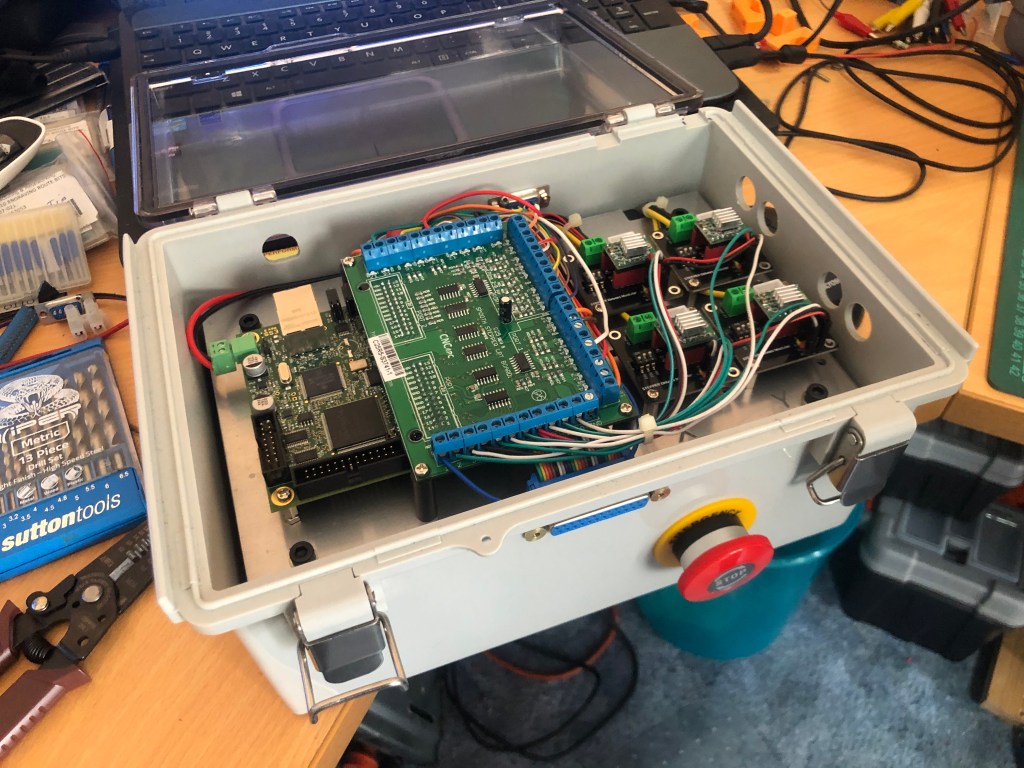

Maybe I will make a start on the electronics enclosure meanwhile.

Here is a photo of Stuart’s mini mill electronics box, which contains the breakout board, 4 stepper motor controllers, a power supply, etc etc. He certainly exhibits a standard for the rest of us to try to achieve. I will just copy what he has done. That box of tricks should be useful for any other CNC machines which I might make.

Always enjoy these updates and your practical approach to problem solving, John. And looking forward to seeing the finished Constitution.

LikeLiked by 1 person

How strong is the PLA material? The print standard looks good!

Peter

LikeLiked by 1 person

Hi Peter,

It seems that 3D printing and PLA filament has come a long way since I first used it about 6 years ago. These are the best prints that I have ever printed. They seem very strong and tough, and quite a good surface finish. The PLA is the one sold by the company (QIDI) who made the printer. About double the price of cheaper brands. The printer is also a good mid range, mid priced model. And I have learned a lot since starting 6 years ago.

PLA by nature is a tough plastic. Just not very resistant to UV light and high temperatures, but very suitable to the indoor CNC mill project. John.

LikeLiked by 1 person