Making Spars on the CNC Mini Mill

by John

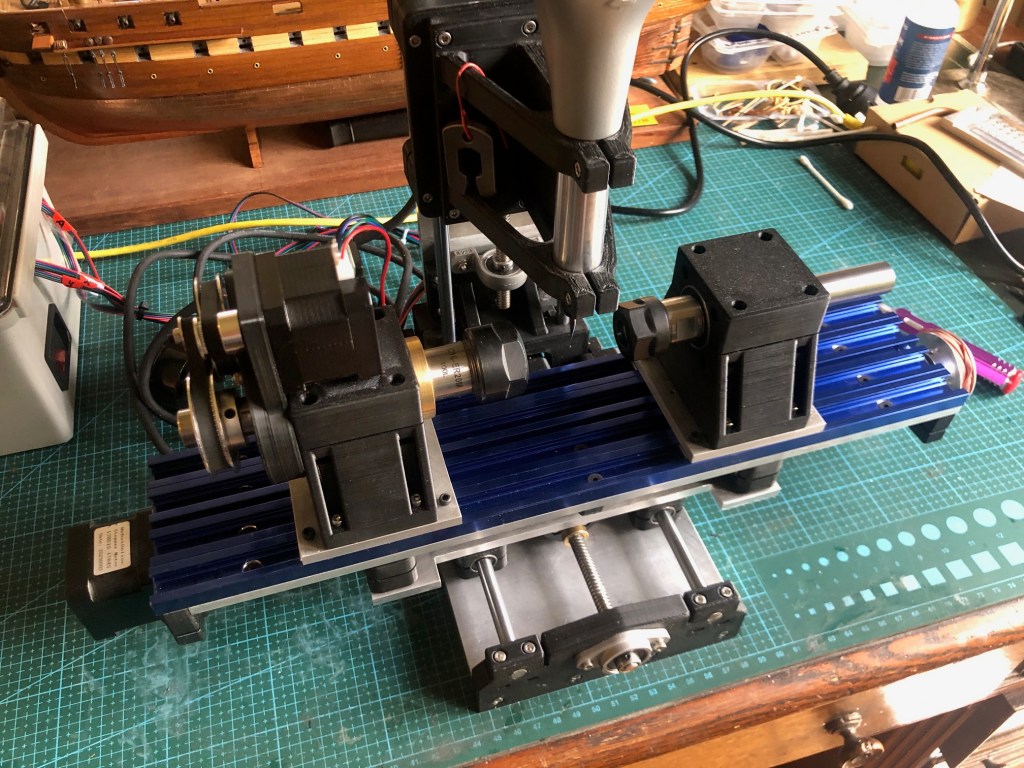

Now that the CNC seizing serving machine is functioning properly I have turned my attention back to the CNC Mini Mill and USS Constitution model.

The masts and bowsprit are sitting in place, but not fastened, except with temporary, fine, copper wire stays so I can measure the length of shrouds and stays for the permanent standing rigging. They need to be removed again so I can apply iron hoops or facsimilies to the lower sections. Even then the masts will be removeable, in case future repairs are required.

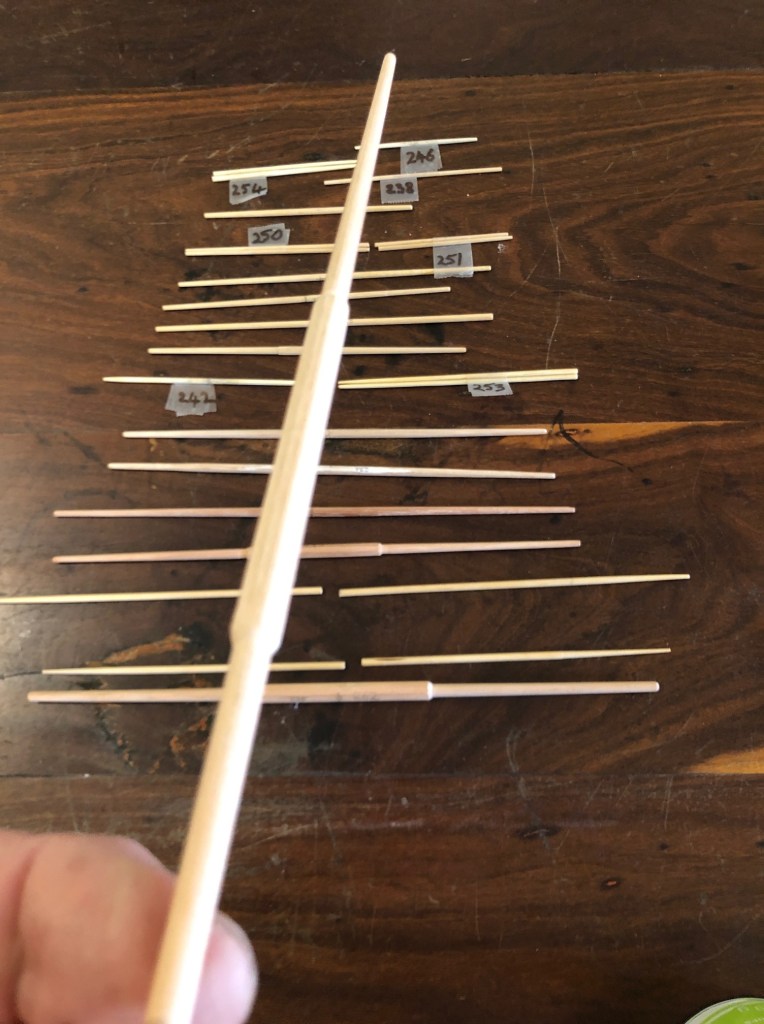

But in a couple of sessions I used the CNC mini mill to make the spars. There are 24 of them varying in length from 60mm to 310mm, and diameters from 2mm to 7mm. They are all tapered, and 3 of them have central octagonal or hexagonal sections, so making them on the CNC mini mill seemed like the ideal tool for the job.

There was some testing of the depth of cuts with a 3mm end mill in the Proxxon spindle at 16-20,000 rpm. The limiting factor was the power of the Nema 17 stepper motor rotating the headstock at about 100rpm. The steppers moving the X,Y and Z axes had no issues. The other limiting factor was the small diameter of some spars. At 1 to 2 mm diameter they sometimes flexed and started whipping, and in one case broke completely. I had to steady the workpiece sometimes using my finger as a steady, to absorb the vibrations and stop the whipping. I counted my fingers after each run, but none seemed to be missing.

Another factor to consider was the mill maximum distance between centers of 150mm. The bigger spars had to be done in 3 sections, repositioning the spar position each time. Not difficult, but increased the time taken for the job.

I was pleased with the surface finish after milling. A quick light hand sand, taking under a minute for each spar was all that was required.

The mill worked very well. Return to dimensions was accurate, and the finish was good. It took a while to get a production run going, re- learning the commands and G codes, and the first spar took a couple of hours, but after a while I was producing one every 5-10 minutes.

Next step for the spars is to attach the footropes, blocks, and other fittings. I will lacquer them. No paint.

From Bruce in Colorado:

John: I enjoy reading your posts even though your techno skills are light years ahead of anything I will ever achieve. Your machines fascinate me!

It was interesting seeing your Mamoli sheet. The bottom right corner is cut off so I cannot see which number sheet it is. I have a similar sheet with actual sizes for each spar but my sheet does not have any pictures of the ship like I see on your sheet. That would be a big help. As near as I can tell, my kit is from around 1982, but I would imagine there were several editions or versions of the plans.

Bruce

LikeLike

Hi Bruce,

Thankyou for the nice feedback.

My plans are dated 1982. They contain instructions in 4 languages including English.

The page with the spars is “Tavola 15”. (page 15 I guess?) There are 15 A1 pages and 2 A0 pages.

If it would help I could get them scanned and send you the electronic files at cost.

John

LikeLike

Thanks John for the offer. I wasn’t quite clear in my comment. There are ship pictures on my Sheet 15 A1 but just not the same as yours. I will wait until I get to that point and let you know if I need further detail. Again, I am really enjoying your build and studying your pictures. They are excellent!

LikeLike