Making Copper Rings

by John

When I purchased it, the Mamoli kit of bits for the USS Constitution model had been opened, and it was at least 40 years old. Also, there was no inventory of parts to check whether everything was present.

So, not surprisingly, there were a few deficiencies. Some wood sizes, some metal fittings, and brass rings. Wood can be purchased, although the later purchases often did not exactly match that supplied from Italy. Fittings can be made, sometimes from workshop supplies, sometimes 3d printed with PLA. The PLA fittings were surprisingly strong and accurate, and when painted could not be distinguished from the originals.

Brass rings 3mm OD 2mm ID were supplied, but as I commenced the rigging it was obvious that there would be nowhere near enough of them. Also, the 3mm size seemed too big for some of the applications. And I did not want to wait for replacements to arrive from the Melbourne model ship supplies, or from China.

So I decided to make some rings. I did not have any brass wire the correct 0.5mm diameter, but I did have some 0.4mm dia copper wire. The 0.1mm difference does not sound much, but it does look significantly thinner. Also, the copper wire is quite soft and bends easily, so I wondered whether it would retain its shape under the strain of the rigging ropes. So I made some and tested them.

Love how cool this blog is. I’m so happy google accidentally directed me here when searching for some wildly specific metalworking question for a customer. I’m just in sales but a hobbyist on the fab side and my favorite part of the job is shop tours.

LikeLiked by 1 person

It is always interesting to read your missives, which always give me insights into strategies of solving problems as you progress through your undertakings.

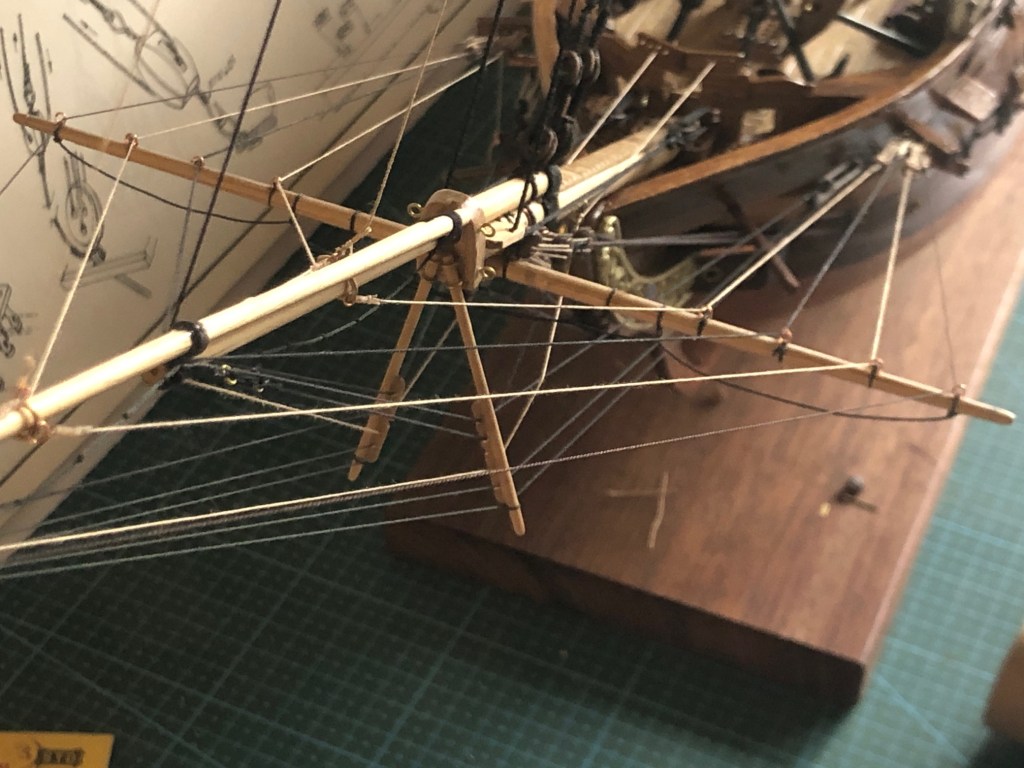

The spritsail spar is another fine example of the difficulty of rigging a ship; you’ve shown many of them through the stages of documenting the project, which I’ve found very thoughtful and accurate.

I suggest that we meet in Boston and have a good look at the Constitution together this Australian winter.

Better yet, you are welcome to come to our home in Hawaii on the way there. I’d really like to meet you (pl) after these many years of communications.

Aloha,

Richard

LikeLiked by 1 person

Likewise Richard, I would really like to meet you face to face, and to see Constitution. And to visit South Carolina. And it has been too long since we visited Hawaii. Regrettably my wife’s health does not allow travelling, and I would not like to leave her at home alone.

But I do appreciate your invitation, very much and very sincerely.

I always enjoy your messages.

John.

LikeLike