Artificial Intelligence in the Workshop

by John

I was making a fence for the disk sander, using my CNC mill semi manually, i.e. issuing commands from the keyboard, when I re-zero’d the Z axis. But forgot to hit enter. And proceeded to the next command which was a Z movement, and watched in horror as the 3 jaw drill chuck headed rapidly towards the workpiece in the mill vice.

I hit the big red panic stop as the chuck with a 2.5mm drill bit hit the vice. The drill bit was buggered, and the chuck jaws, still rotating, made an ugly pattern in the hardened mill vice jaw.

After cursing my own stupidity, I raised the Z axis, and tried to release the chuck jaws to remove the stump of the drill bit, but the the keyless chuck was jammed.

This was not good. I hate to admit it to my readers, but this is not the first 3 jaw chuck to suffer this fate. I have had to replace 2 or 3 chucks over the years, for exactly the same type of mishap.

So, I tried my usual tricks. With the chuck in a large vice, and a large Stillson wrench I tried to undo the chuck. But it was really jammed. Bugger. bugger. bugger. I had tried first with a large but more delicate and kinder pin wrench, but that was totally useless, hence the move to the Stillson.

I contacted ChatGPT, and asked for information and advice. By this time I had partially disassembled the chuck, but still could not rotate the knurled ring to adjust the jaw opening mechanism.

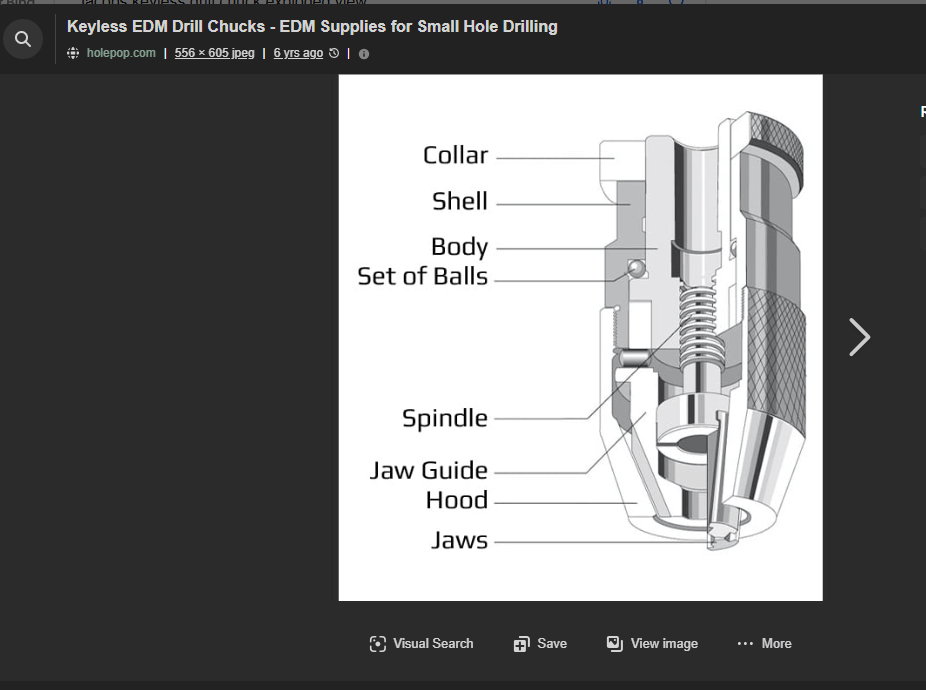

Chat GPT was sympathetic and polite, and gave a detailed explanation as to what had happened internally to cause the jam. It even provided a link to a diagram of the chuck mechanism.

It suggested that I just replace the chuck, because something in the mechanism was bent, broken, or brinelled. Not fixable. Chuck manufacturers do not regard these chucks as repairable items.

I had managed to unscrew the hood, and remove the jaws and the spindle, and figured that the jam had occurred between the shell and the body of the chuck, probably at the level of the balls. Maybe.

So I ordered a new chuck.

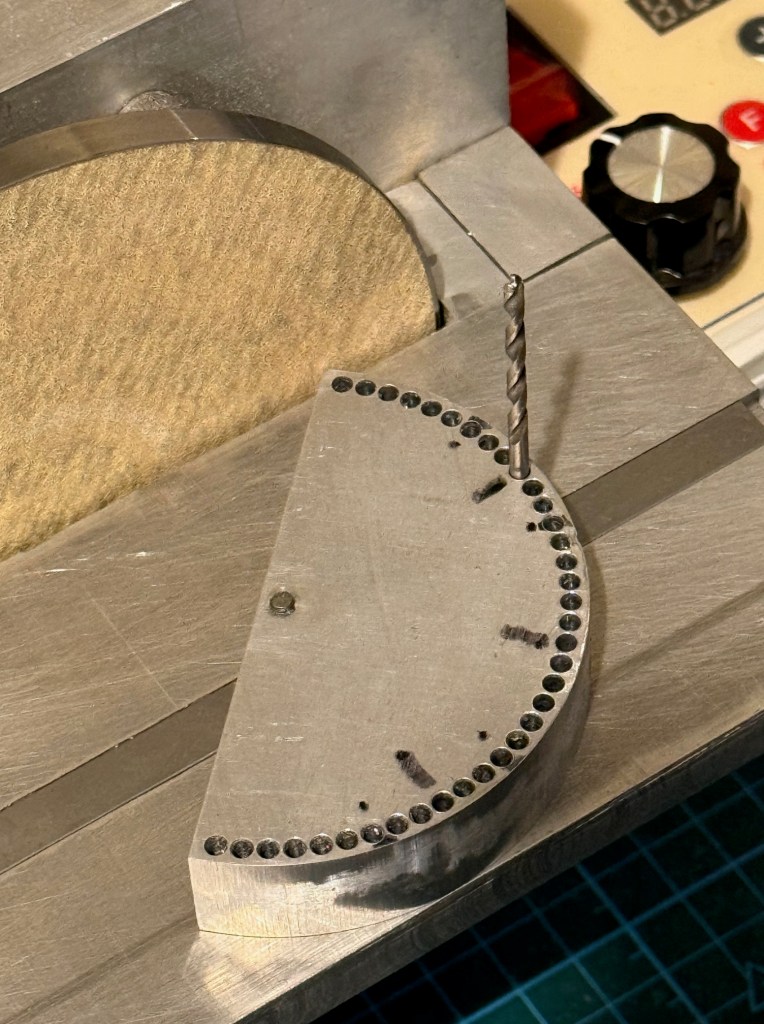

But I still wanted to continue with my job, which was making a protractor fence for the disk sander shown in the previous post. And the buggered chuck was my best one, and the job involved accurately drilling 38 holes, 2.5mm diameter, through 16mm of aluminium.

With nothing to lose, I put the chuck in my biggest vice, and pressed the body of the chuck to release the pressure on the balls. But nothing happened. It was REALLY tight. Should I apply heat?? Nah. I wound the vice handle with all of my strength, and then heard a slight “creak”. Either something had cracked, or something had moved. I hoped that it was not the thread of my 6″ Dawn vice.

So, took the chuck out of the vice, and tried to move the adjusting knurled cover.

And bugger me, it moved. Not only moved, but moved freely.

So I reassembled the chuck, jaws and all, and tried it again. And not only did the adjusting mechanism move, but the jaws operated smoothly, freely, and normally!

But! Is the chuck still accurate enough to finish my job??

In triumph, I sent a message to ChatGPT, Thanking Him/It for the helpful information, and detailing my fix. In the space of one second, ChatGPT congratulated me! And offered a detailed explanation of what must have occurred to explain the sequence of events. And advised me to use the new chuck when it arrives, and use the damaged one only for non critical jobs.

All very polite, respectful, congratulatory, sensible and helpful.

A very satisfying conversation.

Now I am thinking.

That conversation was actually more helpful and satisfying than most conversations that I have had with actual human beings.

And it was with a machine!

p.s. SWMBO’s response to this story was “Well, I am not at all surprised that you are happier to talk to a machine than a human.” !!

Can relate to that situation. Using the machine with the keyboard in manual mode. When setting a X Axis did not notice that I had missed a decimal point. Lucky the chuck did not contact anything but never did find the remains of the 4mm endmill

LikeLiked by 1 person