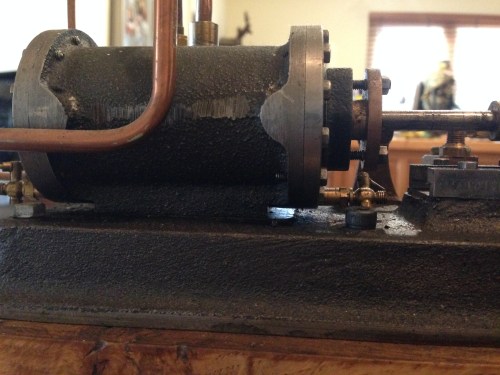

Bolton 7

For reader Timothy, I hope that these photos answer your query.

The Bolton7 was my first attempt at engine building. As you can see, the finish leaves a lot to be desired.

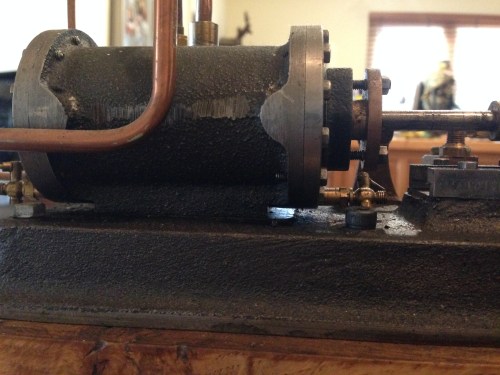

For reader Timothy, I hope that these photos answer your query.

The Bolton7 was my first attempt at engine building. As you can see, the finish leaves a lot to be desired.