Solid Copper Riveting. What I have learned.

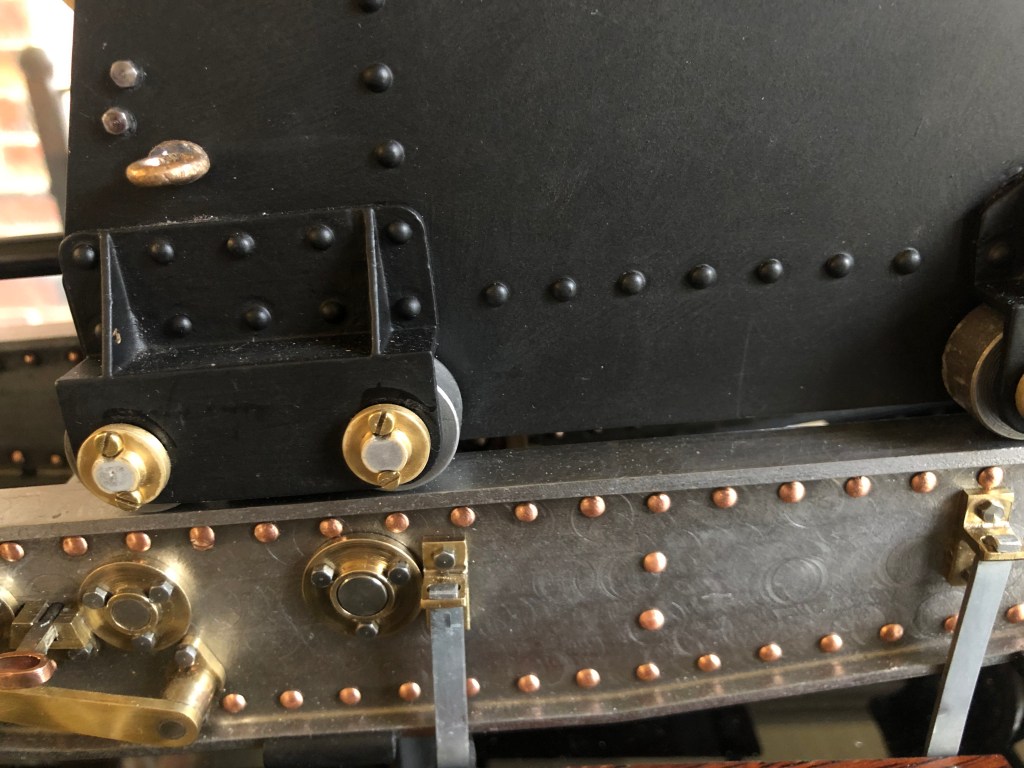

I started with virtually no knowledge about this subject, but I had to learn quickly in order to finish my 1:10 model Armstrong rifled muzzle loading 1866 cannon. I finished the job, not perfectly, but adequately, and this is what I have learned so far.

- Copper rivets are annealed when purchased, but as soon as you start hammering them, they harden.

- You need one hand to hold the work. If you use a hammer, and hold a snap, that uses 2 hands. So either use a third hand or use a pneumatic hammer with the snap attached. That leaves a hand free to hold the job. The pneumatic hammer size must be appropriate for the job. I purchased one from the country of Taiwan. It cost $AUD120. Seems to be excellent quality.

- The compressor pressure is critical. The air setting on the hammer is critical. Experiment on waste material first!

- Hold the fixed snap in a strong vise.

- The snaps need to be accurately made for the rivet size. Try them on waste material before using them on the job.

- Rivets of the same size but from different manufacturers will differ in finished appearance. Get your rivets from a single supplier in one batch. Order 10-20% more than you think that you will need. You will lose some, and muck up the insertion in some.

- The surface of the snaps should be smooth, with rounded edges. A polished finish is best.

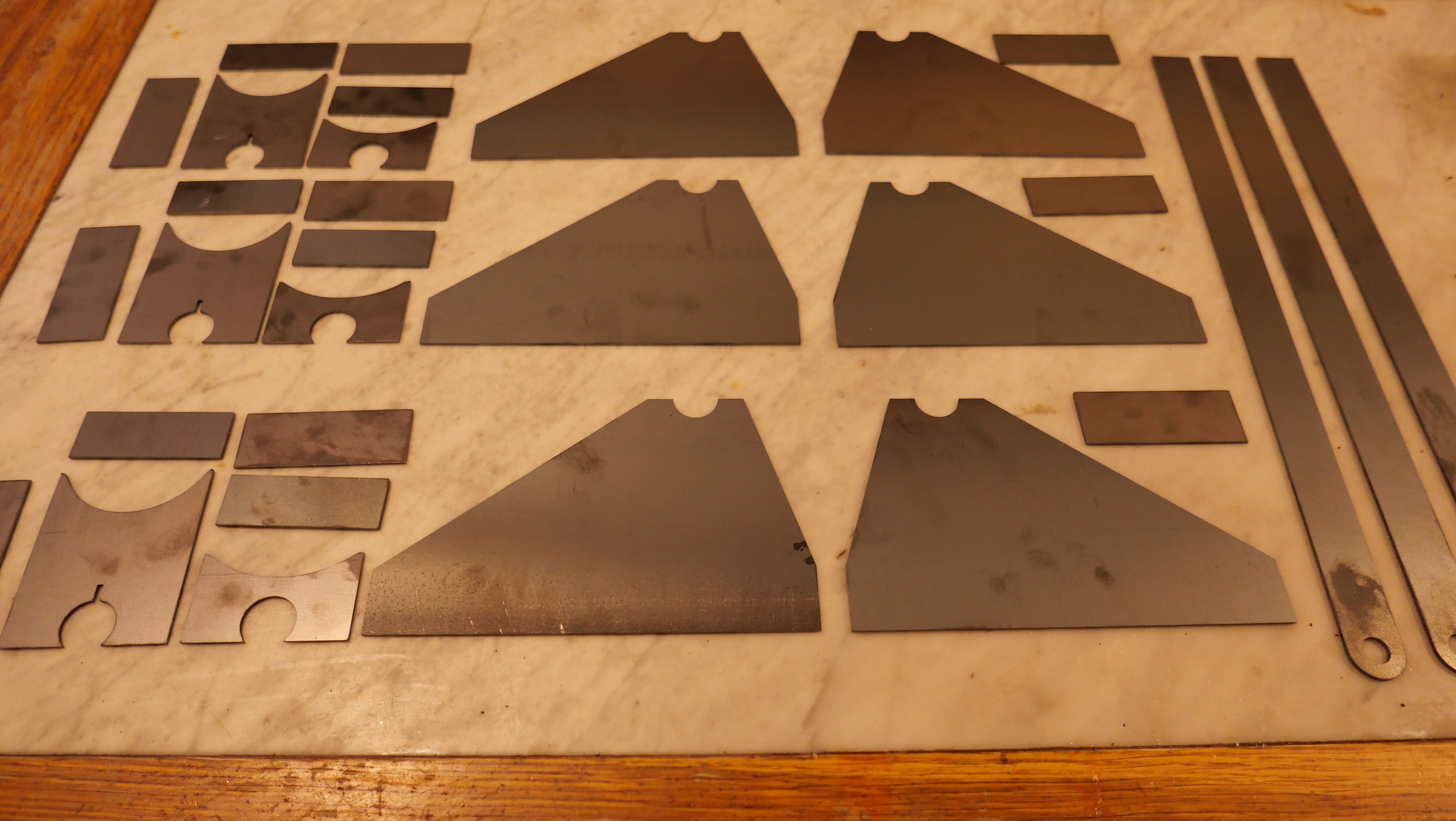

- A complex job, with internal rivet ends, requires custom made snaps. Be prepared to make them. For the carriage parts I used 5 different shaped snaps. For copper rivets, mild steel snaps were quite adequate.

- Some rivets will not insert well. Just remove them, and try again.

- To remove a rivet, grind off one head. It might then push out with a steel pin. If necessary, drill through the shaft with a small drill (say 1-1.5mm for a 2mm rivet), then punch the remains out of the job.

- The rivet length must be precise. The head which is formed by the snap was best if the shaft length was 2.5mm longer than the total thickness of the materials to be joined. There are tables to determine the lengths.

- To shorten copper rivets, drill a hole in steel plate which is the exact thickness of the desired rivet length, the exact diameter of the rivet. With the rivet in the hole, snip the rivet to length with wire cutters, then belt sand it to length. Push the rivet out backwards.

With grateful thanks to Neil M for expert advice on this subject.