3D Printer Plate Adhesion Problems

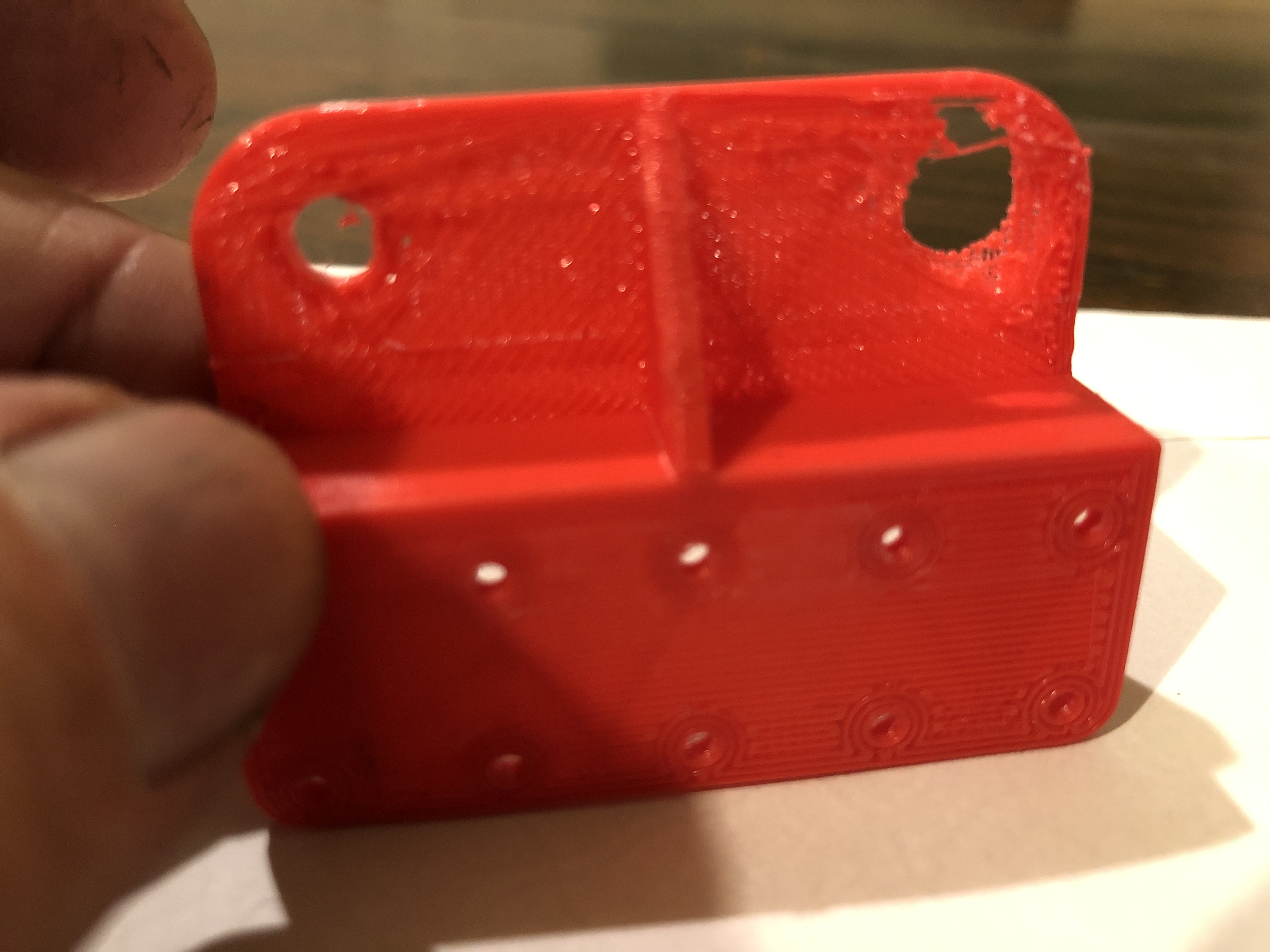

I have been tearing out chunks of hair, and gnashing teeth because prints are failing due to loss of adhesion. And the problem has progressively worsened to the point that the failure rate is now 100%.

And I am thoroughly fed up with throwing bird’s nest conglomerations of PLA in the bin.

I have tried the following remedies…….

Varying the bed temperatures and extruder temperatures up and down. Various combinations and permutations.

Cleaning the bed after every print, with acetone and scraping.

Checking and rechecking the bed for level.

Replacing the extruder nozzle.

Changing the PLA to brand new stock.

Printing on a different part of the bed rather than the default centre.

Today, I searched the net for solutions, and I decided that I had tried all of them, EXCEPT, replacing the bed surface.

I have been using a 3M product, designed for 3D printing, designated 9080A. Today I RTFM. If you do not know what that stands for, try “Read the F’ing Manual”. So I RTFM’d.

It seems that 9080A is good only for 10 uses, then should be replaced. OK. Penny drop time. I have been using the printer for 18 months with the same 9080A sheet. Maybe 50 times?

Back to Amazon, order some more 9080A sheets. Meanwhile I will revert to the borosilicate glass sheet that was originally supplied with the printer.