Trevithick Dredger Engine….progress

Finishing bits on the engine assembly. The stuffing box, the gland, and a threaded plug in the throttle cylinder. Throttle valve, stem direction valve, piston and piston rod next.

Finishing bits on the engine assembly. The stuffing box, the gland, and a threaded plug in the throttle cylinder. Throttle valve, stem direction valve, piston and piston rod next.

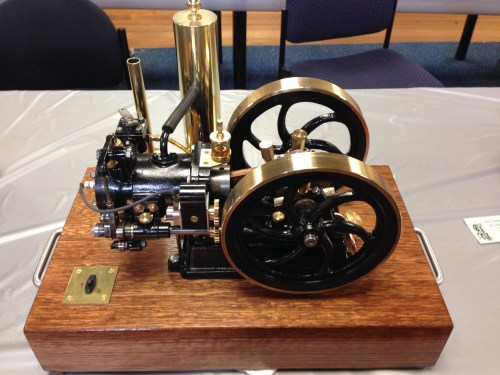

The following short videos show some of the engines on display by GSMEE in the Vintage Machinery Shed at the recent Geelong Show. GSMEE is Geelong Society of Model and Experimental Engineers. All engines are running on steam, except of course the Stirling engine, the Farmboy, and the Atkinson engine.

These engines will be running again at the GSMEE exhibition 25-26 Nov 2017, at The Lifestyle Pavillion, The Geelong Showgrounds. Several scale model traction engines, trade exhibits, outside entries, and the engines in the Vintage Machinery Shed will also be on show. The Hatherly Challenge competition will be judged. This year the challenge is to make a reversing horizontal mill engine. Entry is free (gold coin donation accepted with gratitude).

Stirling Engine, running on heat from exhausted steam, spinning a CD with spiral image, made by John V.

Stuart Victoria Twin, made by Malcom W

Bolton12 Beam Engine made by John V

Farmboy internal combustion engine, running on propane, made by Stuart T

Horizontal Mill Engine running on steam, reconditioned by John V, (GSMEE exhibit)

Atkinson Engine, running on petrol, made by Rudi V. FIRST PRIZE.

Stuart 5, running on steam. Reconditioned by Rudi V. GSMEE exhibit.

Beam Engine “Mary”, completed by Stuart T. THIRD PRIZE.

Mill Engine, running on steam GSMEE exhibit.

Mill Engine running on steam. GSMEE exhibit.

Mill Engine, running on steam, made by Malcolm W.

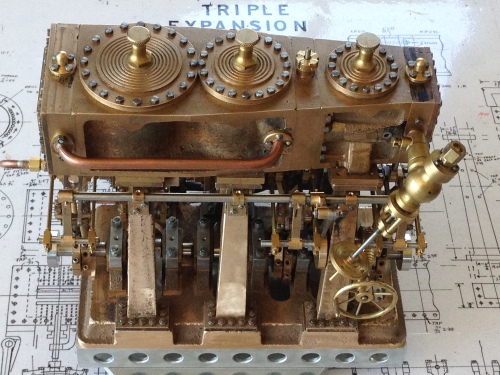

Triple expansion marine steam engine by John V. Almost completed. SECOND PRIZE.

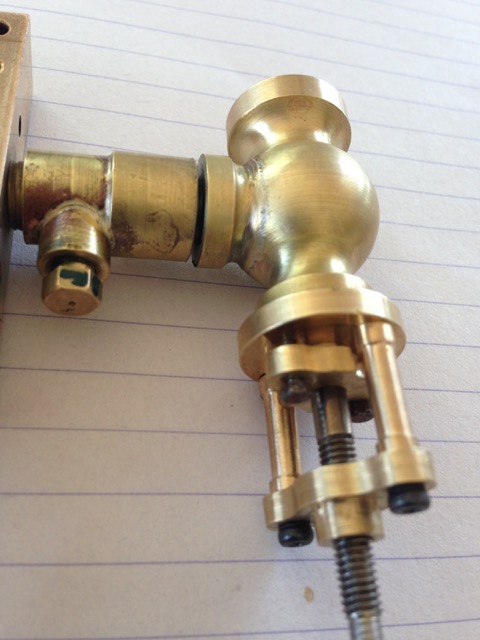

This valve is the one which opens the steam supply from the boiler to the engine. Triple expansion sgeam engines require a minimum of 100 psi, and preferably 120-200psi. But amteur built boilers are rarely certified above 100 psi.

But compressed air gets to 120 psi with no drama. So guess what will power this engine until I get around to making a high pressure boiler.

So the on-off valve needs to be pretty solid, so it does not explode and send hot fragments of metal in all directions.

Here is the main supply valve as specified and built for my triple expansion steam engine.

The lines in the background are a ruled exercise book, just to give a sense of the scale. There are 9 components of precision machined components in this picture. And about 2-3, 8-12 hr very happy days in the workshop to make. This is all made from bar stock.

And this is the handle which controls the on – off steam supply. Pretty sexy hey?

It all attaches to the high pressure steam chest and cylinder.

Hey! I like this shit stuff . Even if most of the rest of humanity is yawning.

Busy at this time of the year.

Making some wooden toys for the grandchildren for Xmas.

Not sure whether these are ducks or chooks. My talented wife brings them to life with colours. When pushed by 1-2 year olds they waddle with an entertaining flap flap walk.

Preparing the surgery building for sale. Removing and storing 34+ years of medical records, moving furniture, arranging repairs and painting etc etc. Feels strange to be no longer a registered medical practitioner, but I know that it was the correct decision to retire. It has taken 2 years to totally burn the bridges by dropping my medical registration, and selling the surgery etc.

Model Engineering Club annual exhibition.

This model quartz crusher at the exhibition was driven by a hit and miss engine.

Another superb engine at our exhibition.

Plus ongoing military history book reading and reviews.

Slashing long grass, to reduce the summer fire risk.

Assembling and installing a kitchen into a rental property.

So it was a treat to get some time in the workshop today. I had previously made the layshaft brackets for the triple expansion steam engine, so I spent a happy few hours setting up an angle jig on the milling machine to drill and tap holes to attach the brackets.

This is the setup. An adjustable angle plate was bolted to the milling table, and the angle was set so the columns were horizontal. The layshaft brackets were Super glued to the columns with the shaft in place after filing to get the brackets quite level. The holes were spotted through, then drilled (1.6mm) and tapped (2mm).

The layshaft bolted in position with M2 nuts and studs. M2 is very similar to BA7, and a lot less expensive, and is stainless steel. Way to go!