My CNC mill is now mostly functioning, although several functions are yet to be connected. The main spindle and XY&Z axes are working, and responding appropriately to Mach3 commands from the laptop computer. It has taken longer than anticipated so far, mainly due to difficulty in understanding manuals supplied from Asia. Axis limit and homing switches, oil pump, coolant pump, work light, and cooling fans still to be connected.

So there has been little of general interest coming out of my workshop. Hence no posts on this site. Not that I have been idle.

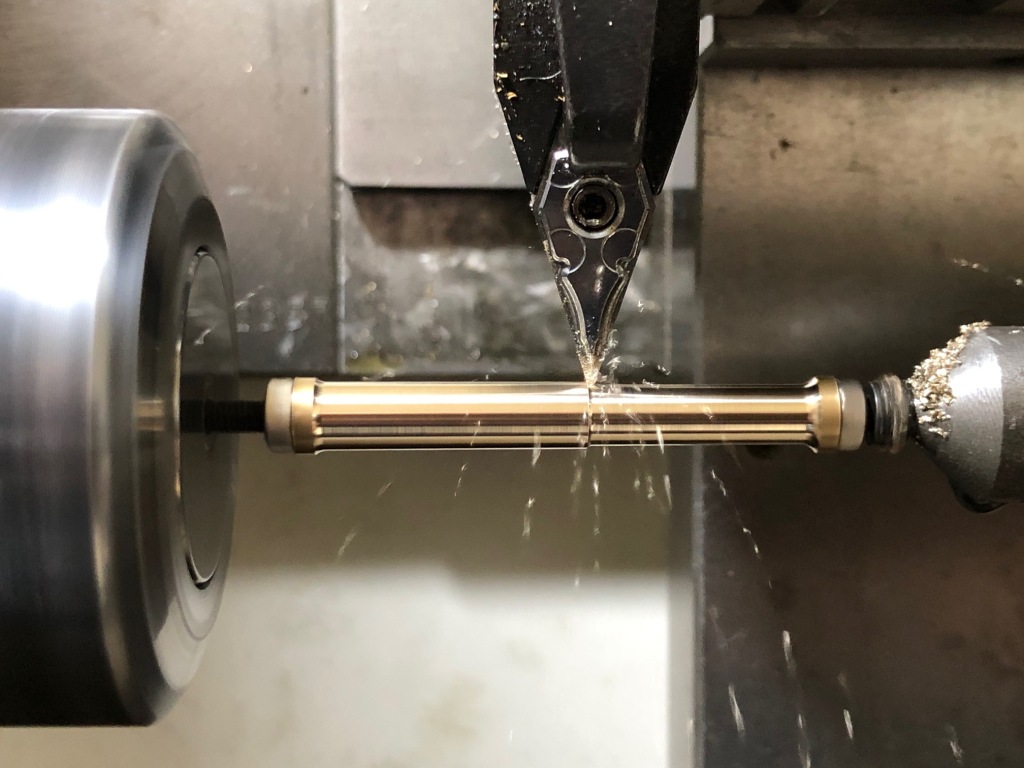

I disassembled the top slide on the Colchester lathe to discover the cause for excessive back-lash. It was a worn acme thread bronze nut. No luck yet in finding a new nut for this 45 year old lathe. I will have to make one. Meanwhile, I used a quick and dirty trick to reduce the back-lash which I will detail soon.

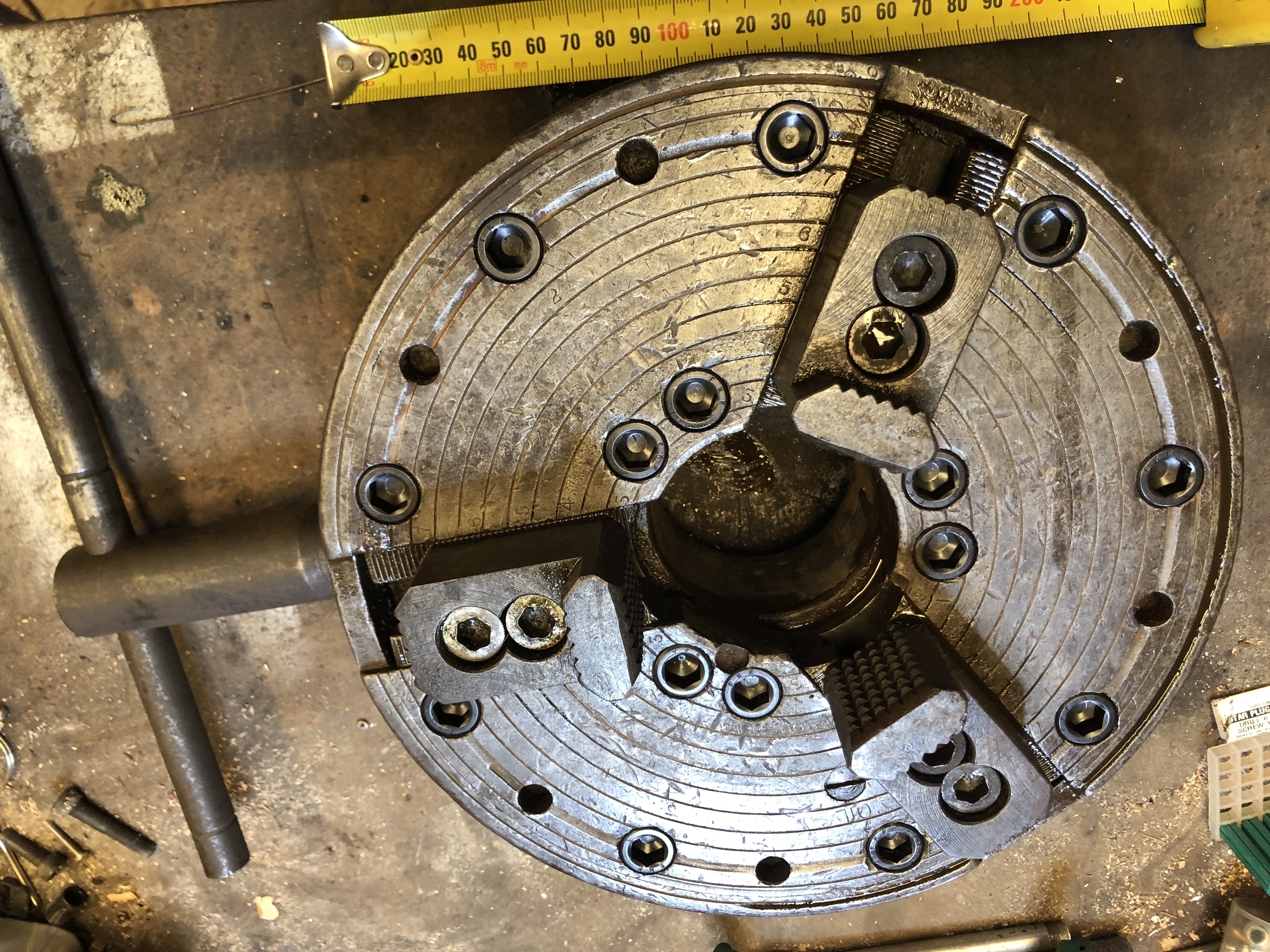

I also cleaned and freed up a 3 jaw 10″ chuck which I bought on Ebay. It was frozen solid, so I soaked it in kerosene bath for a few months. Actually, I forgot all about it while it was in the kerosene, and accidentally rediscovered it. This time, after using an impact screwdriver, I was able to open it up and expose the gears and get them moving. Might be worth a photo also.

And I finally got around to installing piston rings in the triple expansion steam engine. Used Viton O-rings. Not a difficult task, and it should not be difficult to replace them from time to time in future. Will be interesting to see if the engine performance improves.

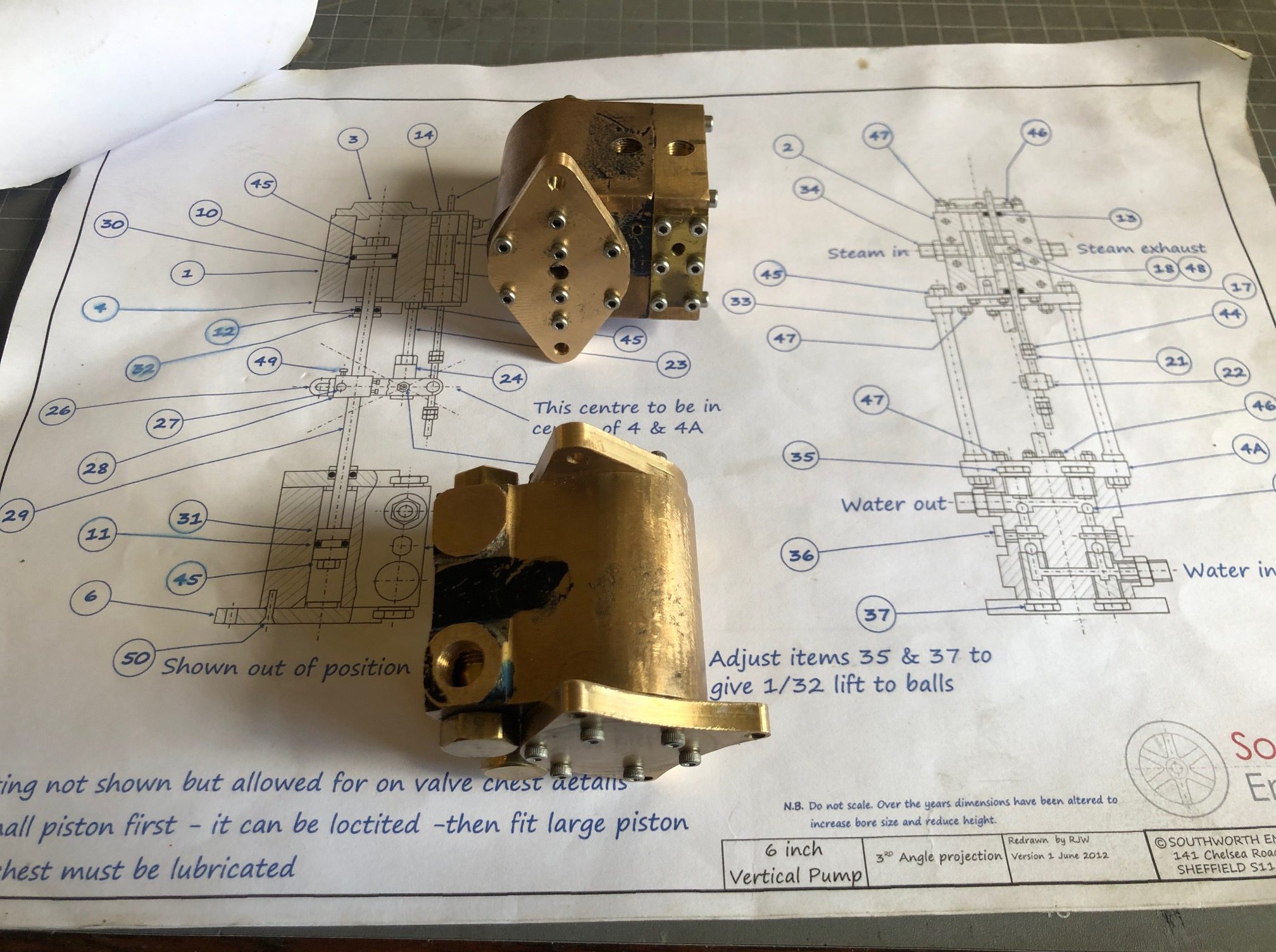

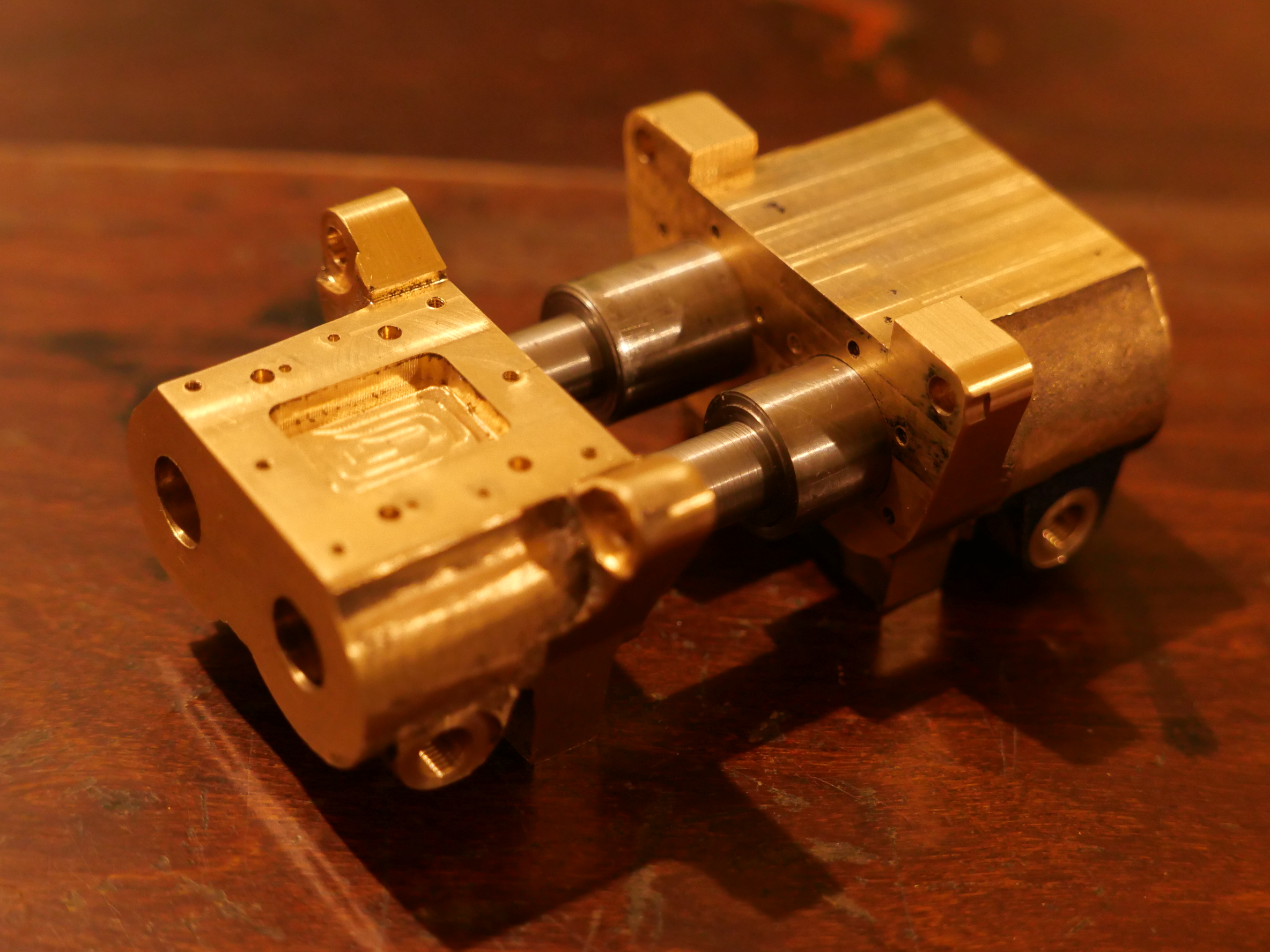

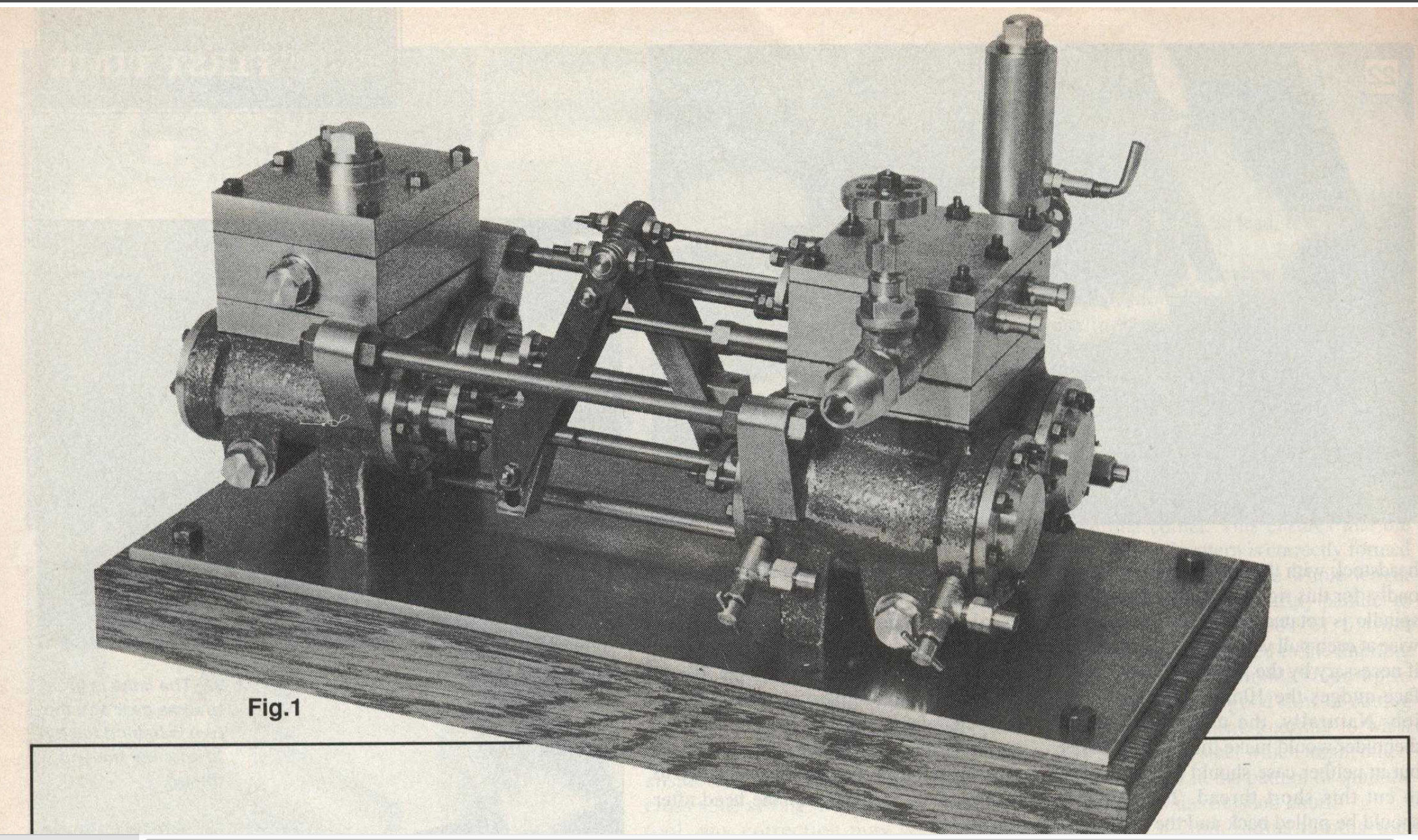

Now to get onto my next project. I have plans and bronze castings for a Southworth design water pump, for replenishing the vertical boiler water while it is in use. It was a surprise to me, just how much water is consumed by a boiler which is powering a model steam engine. To date I have used a hand pump, but having seen a steam powered pump in action, I have decided to make one.

The steam is supplied from the boiler which is being replenished. The pump has to use steam at boiler steam pressure, to force water into the boiler. So the pump has to raise the pressure of the feed water above the pressure of the steam which is powering the pump. The clever pump design uses large steam driven pistons to drive smaller water pump pistons.

Larger steam pistons top right 5/8″ dia, water pistons bottom left 3/8″ dia.

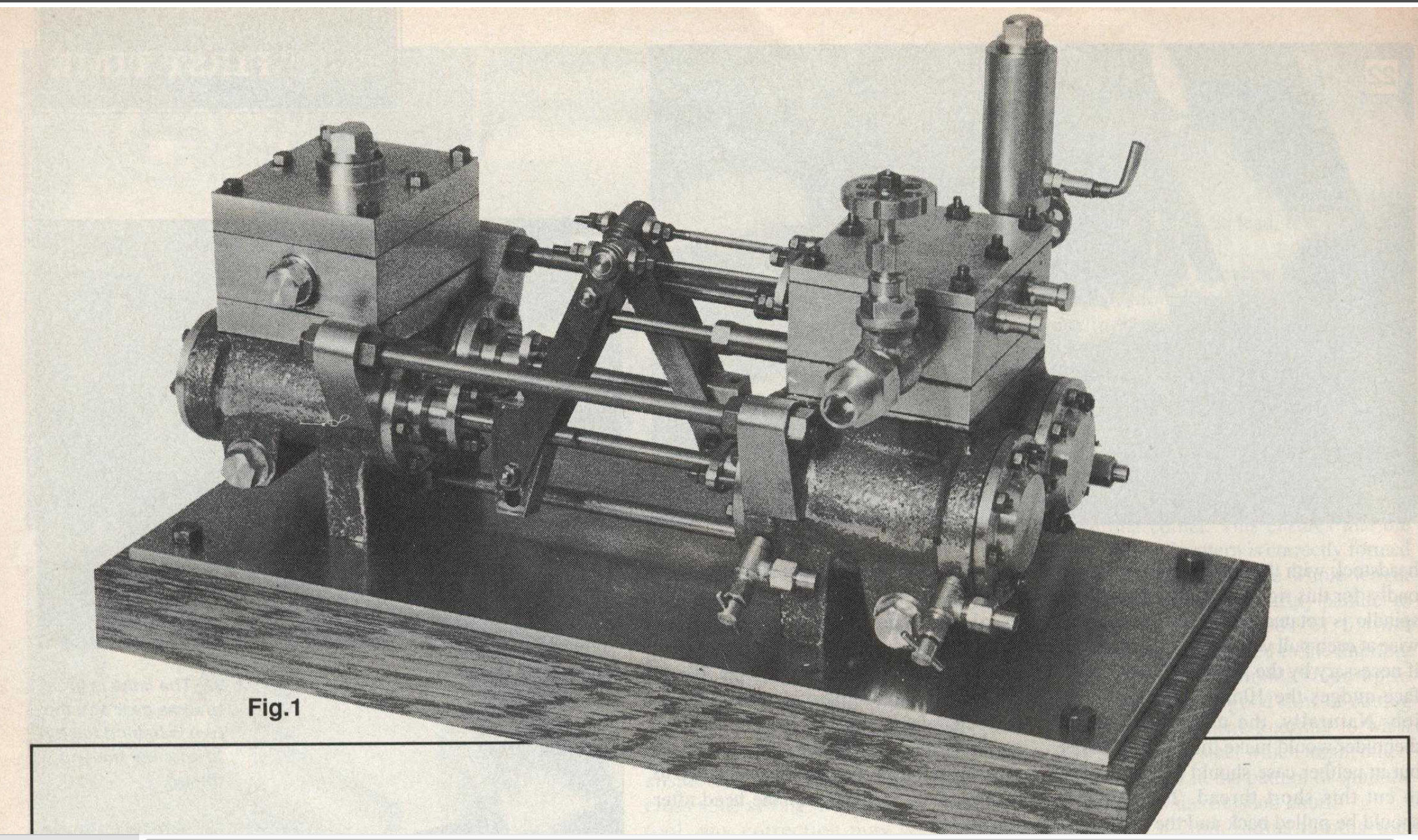

Here is a video of a Southworth pump in action. It was made by Stuart Tankard. Here it is running on compressed air, but I have seen it working similarly on steam. I will be making one of the same design, hopefully approaching this level of finish.

A build of larger version of the pump was described by J. Bertinat in a series of articles “Model Engineer” in 1993 (first article 18 June 1993).

Good quality castings.