Armstrong RML Cannon Trunnions – 2

Silver soldering the trunnions into the barrel and the squared blocks did not go well.

For a start, I did not know the composition of the steel of the barrel. The trunnions were/are silver steel, and the blocks were mild steel. So it is possible that I did not use the best flux.

And the barrel is quite hefty, so I knew that it would require a lot of heat to get it to temperature, and to keep it at soldering temperature. So I used a large oxy-propane torch, and heated it to dull red heat.

The steel pieces fluxed and wired together, ready for heating

It was a cool day, but the heat output from the red hot barrel was ferocious.

Soldered, but one side was not good, and a hammer blow dislodged it. Damn.

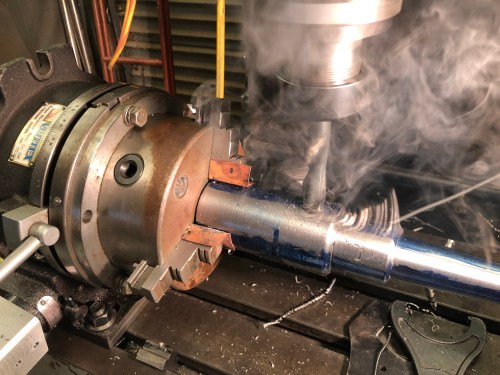

The good side, partially machined.

I dithered about how to deal with the faulty side. I was not enthusiastic about re-soldering it, expecting that the good side would fall apart.

So I cleaned up the pieces, and used high strength, high temperature, Loctite 620, to join the pieces. The machining will test the strength of the joins, so I will give it the full 24 hours before testing it. This is the “reject” barrel.

Still pondering how to join the trunnions of the “good” barrel (front). I will discuss it with my colleagues tomorrow when we have a Model Engineering Society meeting on “Zoom” video link. The 3D printed barrel at back is a handy “how it should look” example.