A Dilemma. Wheels or handles for running back the Armstrong 80pr RML Cannon.

by John

And why I made a significant design change.

When the cannon was fired the recoil pushed the carriage up the 4º slope of the chassis. However, to reload the muzzle loading cannon, the carriage had to be completely at the top of the slope. I know this, from making the model. There is only one position of the carriage on the chassis where the loading arm will properly engage with the muzzle of the barrel.

So, if the recoil did not push the carriage up to exactly the correct position, it had to be wound up to correct position by 2 of the gun crew, operating a handle or wheel on each side of the chassis.

On the first model which I made of the cannon, I copied the wheels which were present on the original cannons at Warrnambool.

Of the seven 80pr Armstrong cannons which I have been able to examine, the Warrnambool pair are the only ones with existing winding back wheels or handles. So that is what I made for the first model which I made, and what I had planned and made for the 2nd model.

But, I was always a bit dubious about the large, and rather unwieldy wheels. Would the original Armstrong designers have specified such wheels? Then one of my readers independently questioned the wheels, so I delved more deeply.

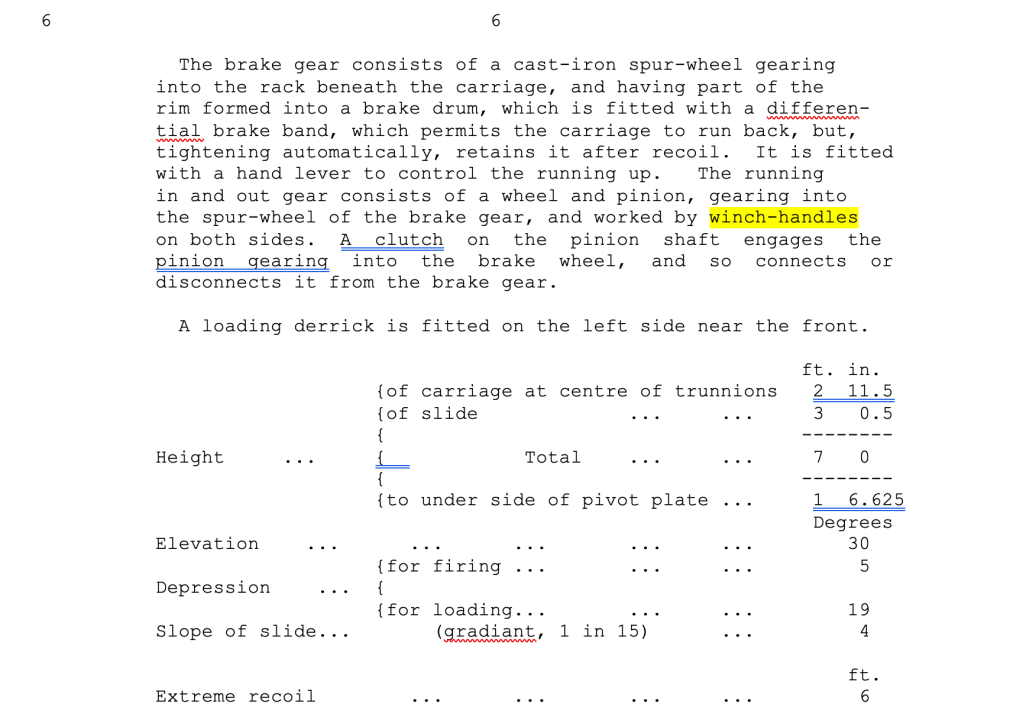

The 80pr cannon is essentially a copy of the 64 pr Armstrong cannons, the main difference being in the construction of the barrel. The 80pr barrels used the new method of winding white hot strips of iron around a mandrel, which made them able to accept larger charges of gunpowder, and heavier projectiles.

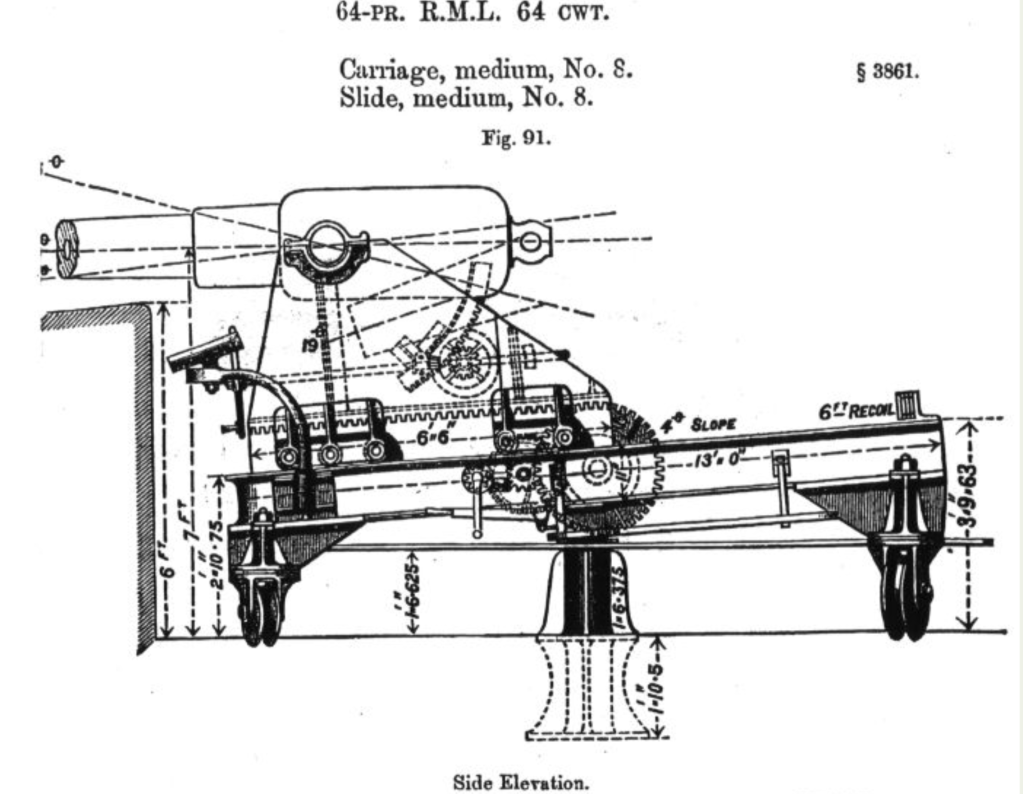

I could not find any plans or diagrams of the 80pr cannons, but I did find these drawings of the 64 pr’s on a very similar iron chassis….

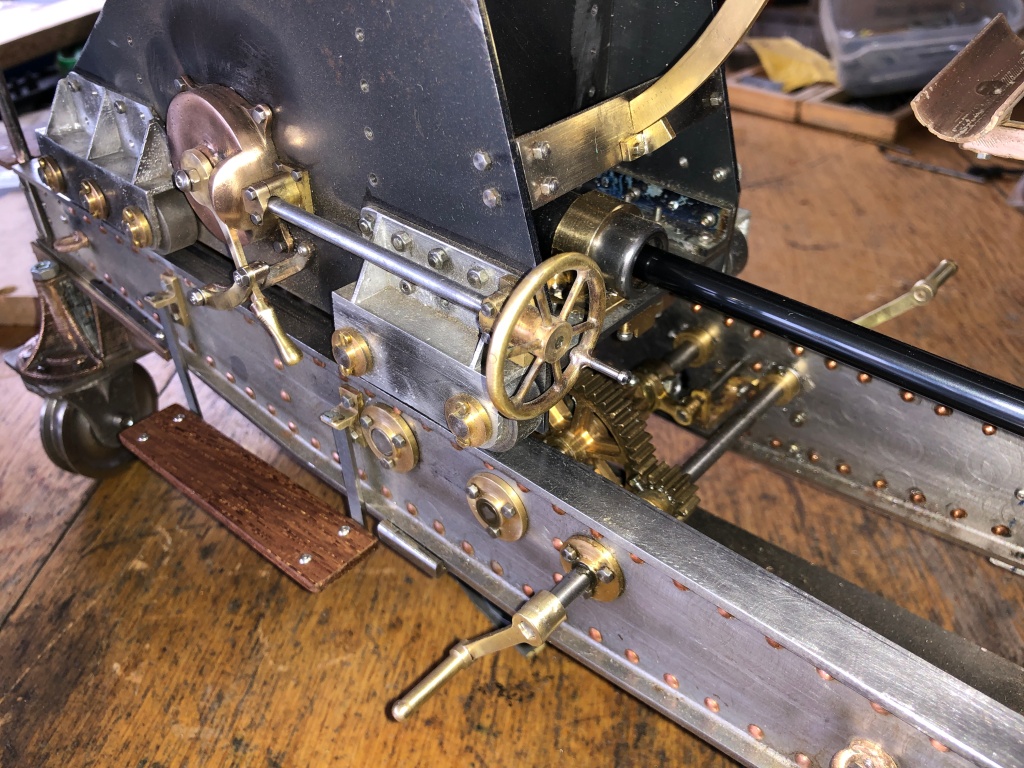

So, I have made handles for my 2nd model…..

Then, the instruction manual for the 80pr, which I saw for the first time a month or so ago, specifies that after winding back, the HANDLES are laid under the chassis. Not the WHEELS, but the HANDLES.

So, I rest my case. Crank handles it is, unless some other convincing evidence comes to hand.

P.S. Casting the Chess Men. I am still feeling a bit despondent about that last failure. I have some ideas about better techniques, but I am not moved to try again. At least at present. For one thing, the failed pieces are really quite heavy, and I wonder whether even if successfully made, they would feel good to use. So I am moving back to finish the cannon, and will wait see if there is some inspiration to redo the chess men. Also, I am still fixing the CNC lathe with the dead computer. Have changed the interface to a smooth stepper, and laptop, but there are still some issues. Stuart T installed the smooth stepper, and reconfigured Mach 3, but the smooth stepper would not work. So Stuart used another identical smooth stepper board, and that works. Stuart is still trying to figure out whether I bought a dud smooth stepper board.

Ahhh Sherlock Holmes …it is amazing how you have to study and gleen bits of information here and there to be able to work out the bigger picture. Those handles look right for the purpose as they would have been easier to use than the wheels. Nice job!!

LikeLike

Handles make sense to me, specially if you can quickly remove and lay them under the slide as stated.

They would be a great trap for the crew to bang a shin or knee if left on and jutting out. Guess they originally had some form of quick release.

I wonder if it was as simple as a tapered square? Perhaps inspection of one sans wheel / handle should you ever visit one again?

LikeLiked by 1 person