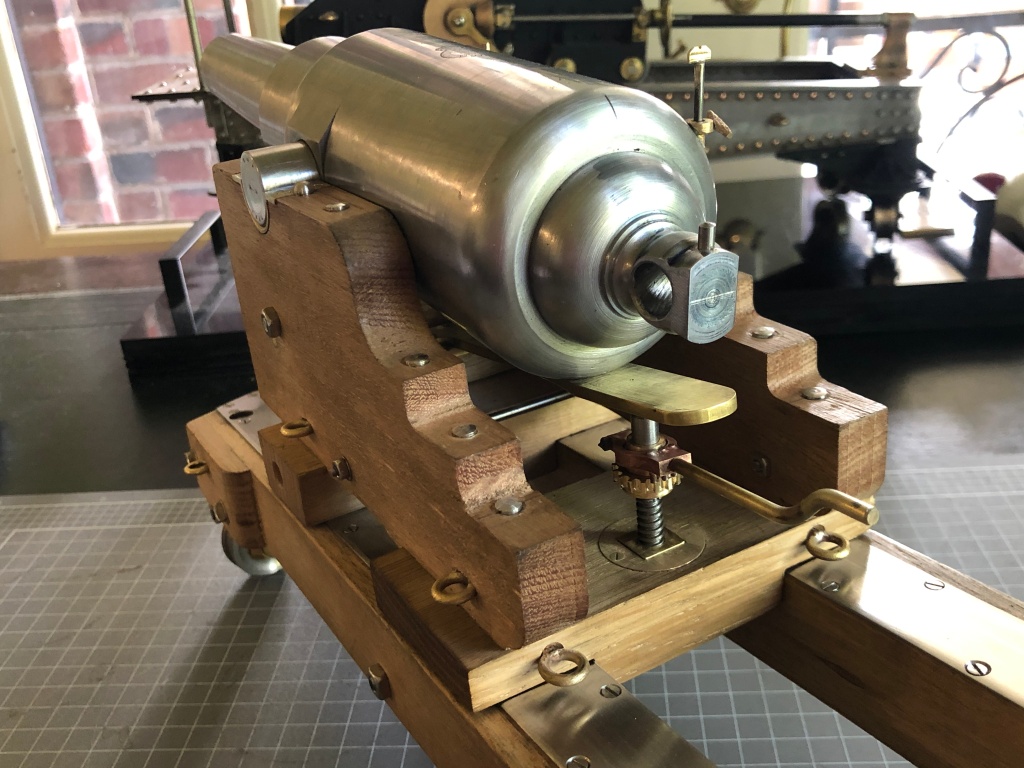

Smith’s Elevating Screw -4 (hopefully final)

by John

Another hot summer day today, so I arrived at my workshop early, before the heat set in.

First I drilled a 1.5mm hole through the Smith’s screw yoke and bracket, for the pin which completes the hinge mechanism which engages and disengages the screw handle. Sounds simple? Well, actually, my intention was insert a 1.0 mm pin, but the first drill bit broke. Now why didn’t I make that sensitive drill press when I first considered it?

So I had to disassemble the parts, and grub and poke around with a fine tungsten probe until all of the bits were out. Then set it up and drill it again. Used a 10BA bolt and nut as the hinge pin.

Then silver soldered some 1mm old drill bits into the previously drilled pin holes as the driving pins for the screw gear.

By this time the day was really heating up.

The threaded post length might need to be adjusted, because I made it slightly longer than thought necessary. I have some spare length at both ends if necessary to adjust.

Very nice!

LikeLike

Thanks Jeff, for the encouragement and help. John

LikeLike