BISMARCK LATHE

by John

This is the lathe which was used to turn the 18.1″ guns of the IJN Yamato. (keep reading. Bismark comes later). The Yamato lathe was purchased by Japan in 1937 from Germany. Japan did not have the capability to make such a huge lathe. The only countries which did have that capability were Britain, USA, and Germany, and Japan did not want the British or Americans to know how big a battleship was being built. The weight of the Yamato (>70,000 tons) was not known to the allies until after WW2! It was the heaviest battleship ever constructed, and carried the biggest guns ever installed on a battleship.

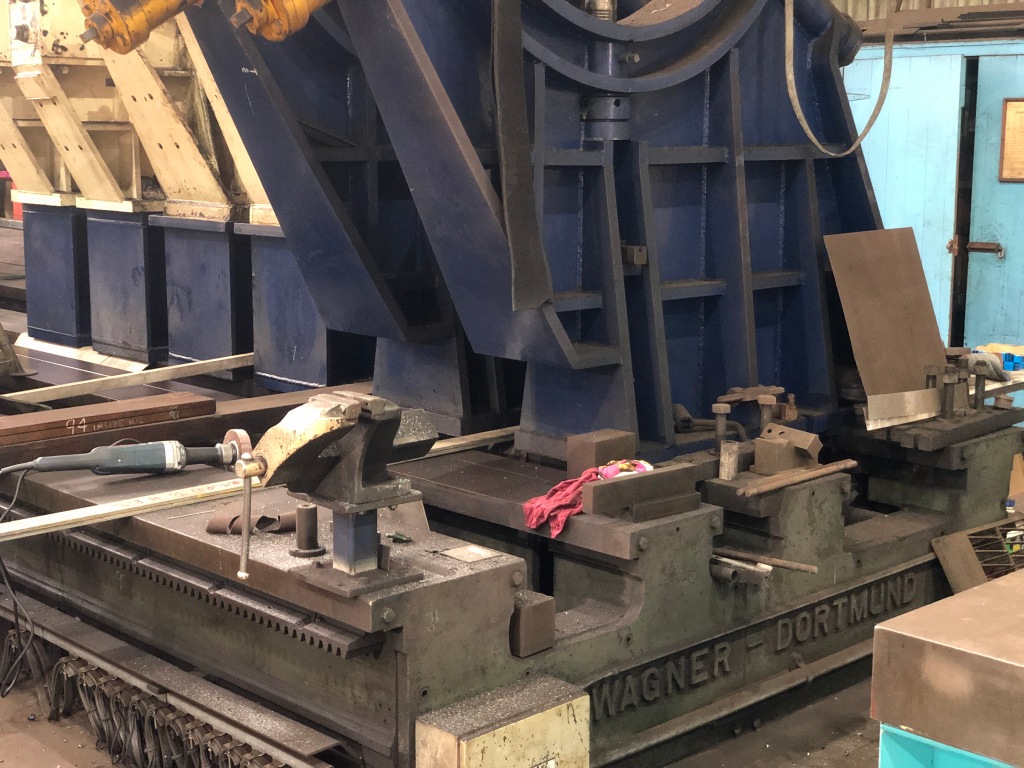

1. Wagner lathe used to manufacture the Yamato and Musashi guns.

I assembled a plastic model of the Yamato earlier this year.

2. 1:350 scale Tamiya model.

….and showed my model engineering club.

Somehow the conversation involved the guns, the Yamato Museum, and the huge lathe which is being moved from its original factory, where it was in use until very recently, to the Yamato Museum.

A senior member of our group, who lives near Yallourn, Victoria, stated that the lathe which made the guns for the Bismarck was currently located in Yallourn, Victoria, Australia!!!

There was a collective dropping of members jaws. WHAT???? HOW??? It cannot be true!!

To cut the story short, further investigation by the member, confirmed that a very large Wagner lathe had been shipped to Australia, as a reparation after WW2. The lathe had been installed in the State Electricity Commission workshop to turn large generating armatures. The SEC workshop was now a private manufacturing factory, and the lathe was still there!!!

The managing director of the company was contacted, and a few weeks later 24 of our club members visited the factory with the tour being conducted by the owner-manager. The factory was fascinating, and the tour lasted over 2 hours, but I shall concentrate on the lathe.

4. The 4 jaw chuck is 8’4″ diameter.

5. The lathe has 2 carriages. The toolpost is over 6′ high. The beds are covered while the tungsten coating is being applied.

6. The tailstock end of the bed, with 6 steadies. Unfortunately I could not find a serial number, but it was probably hidden behind other equipment.

The distance between centres for the lathe is 70’/20m, certainly big enough to have turned the Bismarck guns. The lathe OAL is 90′. The original tailstock and a section of bed was lost at sea in a storm during transportation to Oz. Replacements were found and installed.

Currently the lathe has a 50hp electric motor. It turns between 1 and 20rpm.

7. The factory covers 20,000m3. I could not get a decent camera view of the whole lathe. The headstock is to the left of this shot. This view is one end of one of the six factory bays.

So. That was a great day.

The factory owner manager is searching for documentation about the lathe, which is essential if the Bismarck association (and Tirpitz, and more than a few shore defense guns around France, Denmark, Norway) provenance is to be firmly established. The locals certainly believe that it IS the lathe which made the Bismarck guns. It is possibly true. The Yallourn lathe looks very similar to the Yamato lathe.

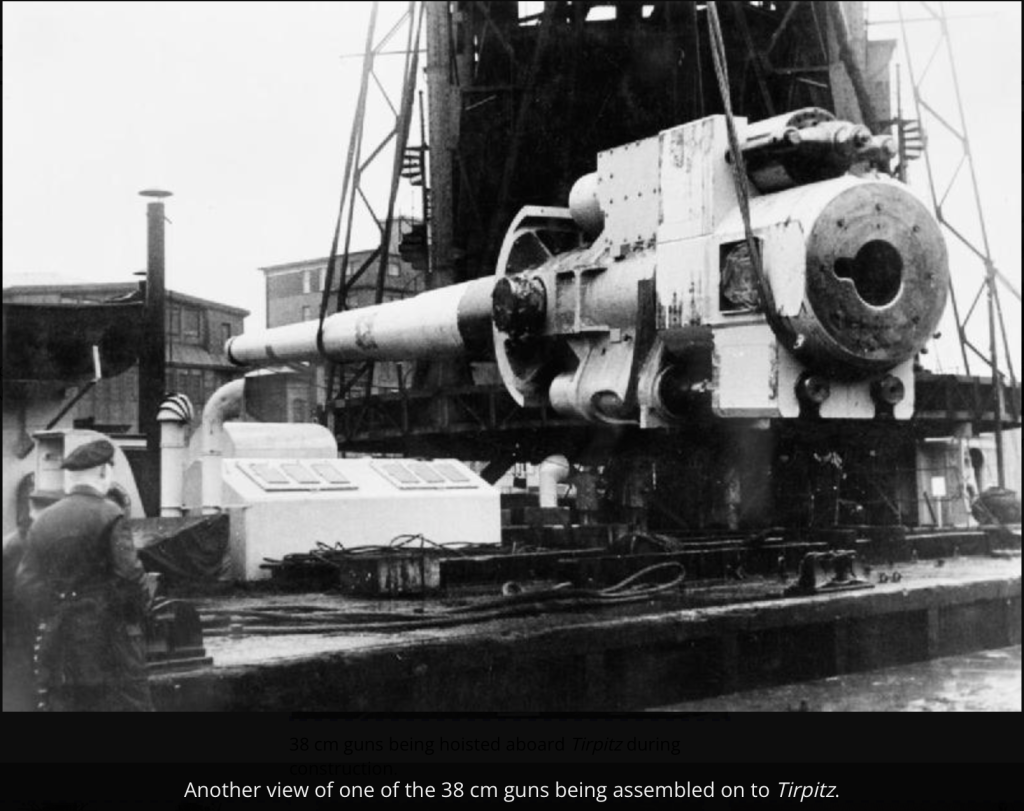

9. Tirpitz was the sister ship of Bismarck. Showing a ~18m long 15″ barrel without the breech.

Great story John. Would have been fascinating to see. Wish I could have been there, but a bit far. Are you sure you can’t fit it in the shed?

LikeLike

SWMBO will not agree to any more lathes

LikeLike

What was said of the Yamato, “The forging of the perfect samurai sword in the age of the gun” ?? or something similar.

LikeLike

Hi John . I spent many an hour on this machine in the 70s and 80s and can add a bit more to the story if you are interested . Unfortunately l don’t have any photos of the jobs we worked on – mainly the LP rotors from Hazelwood PS – but they were always interesting jobs . Regards Lance Fisher .

LikeLike

Hi Lance, yes please, I and many readers would be very interested in any information about the lathe, and the work it performed. John

LikeLike

Got a couple of pics from other Facebook sites , should interest those who never got a chance to see it in action . Would like to talk to you John before l tell your fellow bloggers – ? on how we went about setting up and machining various areas on the rotors . Regards Lance .

LikeLike

Wow, this post is fabulous! I’m dumbfounded by the scale of this beast of a lathe.

Truth be told, I’ve been fascinated by wooden boats of every type but paid little attention to 20th century warships (with the exception of submarines and the USS Missouri) until I followed your model construction of the Yamato and finally understood its size. It’s undoubtedly why I suggested “Sea of Thunder” to you.

LikeLike

and I can’t wait to read it Richard.

LikeLike

Thanks for the recommendation Richard. I am about 1/2 way through Sea of Thunder following your recommendation and it is indeed a most interesting read and study of American and Japanese admirals personalities. Have you listened to Dan Carlin’s analysis of the Japanese in WW2? Another fascinating analysis. “The Japanese are like everyone else, BUT MORE SO”. John

LikeLike

What a find.

I wonder what lathe made that lathe, ad infinitum.

LikeLike

Hi Tim, Yes, you need a lathe to make a lathe, and each iteration gets better. The current owner user of that Wagner lathe believes that it was made in 1898!! And it is still in use!! John

LikeLike

Hi, During 1956 and 1957 school end of year breaks, I worked as an Metal Trades Junior in the Central Workshops in Yallourn. I remember vividly it’s size, you could stand on the carriage to operate it. My only involvement with it was assisting in changing the oil in the headstock. While I was there it was being used to resurface bearing surfaces for the briquette machine crankshafts. They were from memory about 6″ diameter and 15′ long.

LikeLike

Still there, still in use. >120 years old.

LikeLike

Operated this lathe in the 80’s setting up Hazelwood turbines, when the SECV got the lathe they raised the headstock, tailstock, tool beds by approximately 600mm and lengthened by one section to fit turbines and generator rotors, it has a very unique story

LikeLike