Deadeyes. Another Approach.

by John

Following on from the previous post, I was not happy about the requirement of changing the work holding for every deadeye, when I intend to make several hundred of them. The problem is the need to drill holes in one axis (the Z axis) and then to turn or cut the outside circumference and to turn a groove into that outside circumference. Plus rounding over all of the sharp edges. All in a piece of wood which is smaller than a flattened pea.

So, I consulted my expert CNC friend Stuart, on the suggestion of Brendan, another GSMEE member, who remembered Stuart’s brass handwheels which he made on his Boxford and churned out multiple copies.

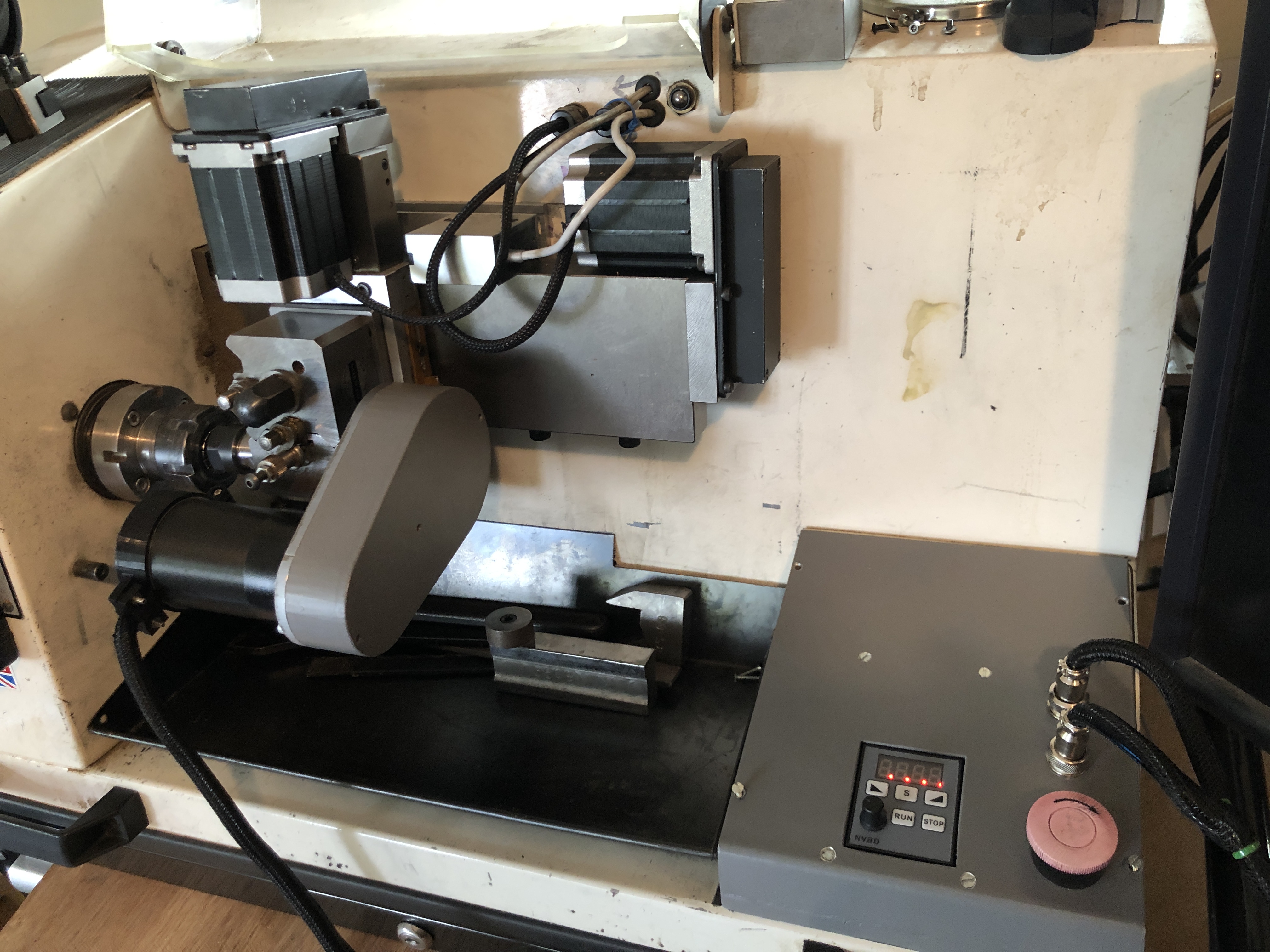

“Why don’t you use the Boxford CNC lathe?” Stuart said. “Ideal for such small objects”. “And use the milling attachment for drilling the face holes”. (without changing anything except the tool)

He came up with that solution in about 10 seconds, after I had explained what a deadeye is.

I had been thinking about solutions for several days, and spent a whole half day making the annular cutter which I described yesterday. Using Stuart’s solution, the annular cutter wont be necessary. Oh well. It will come in handy one day. Maybe.

John I thought you might like to see a few pics of a little thing I made. Â I don’t think I have sent these before, I think I just sent a few pics of the mortar I made. Â It’s 1/10th scale so 1.25 inch diameter. Â I thought it would make a nice little object for the desk. The original is at Hurst Castle and unfortunately the idiots who own it have let the sea wash the sand away until the fort collapsed. Â Now it’s too late they have dumped stones on the shore to stop more erosion. Â An absolute disgrace that it was allowed to happen. Anyway keep up the good work. Thanks Rich Â

LikeLike

Hi Rich, yes I would like to see the photos. If you have trouble posting them here you could send them to me at jviggers@iinet.net.au

John

LikeLike