The Boiler Inspector.

by John

Today I loaded the Fowler 3R traction engine onto its trailer and drove to Werribee, to have an official inspection of the boiler.

This is not a legal requirement, because I can operate my traction engine whenever I please on my own property. But all model engineering Clubs and Societies require a current certificate before they will permit steam engines to be operated at their meetings.

The maker of my traction engine had the boiler inspected and passed about 18 months ago, but that certificate has now expired. So it needed re-certification.

The original test pumped water into the boiler at double the maximum operating pressure to test the boiler for leaks and distortion. The boiler is actually designed to withstand pressures of EIGHT times maximum operating pressure, so the safety factor is reassuring.

But, boiler explosions are horrific, so the caution is understandable.

My boiler is made of copper, thus avoiding the problem of steel boilers which gradually becomed thinned by rust. And my boiler seams were joined by silver soldering, which, if expertly done is as strong as the parent metal. As a matter of interest, the maker of my boiler told me that he had used $AUD1000 of silver solder in the construction of the boiler decades ago!

The test today involved pumping water into the boiler at 25% above maximum operating pressure, and holding it there for 20 minutes, checking the boiler for leaks and distortion. It passed that test without problem.

The next test was for the functioning of the safety valves. I had cleaned them and replaced the balls and polished the seats, and I had seen them blowing off when the pressure was above 100psi, so I was fairly confident that the certification was “in the bag”.

So the fire was lit, and after some coaxing because I had stupidly forgotten to bring the chimney blower, the steam pressure was raised to 100psi. The safety valves started venting off. But, the test is fairly demanding. The fire was roaring, the steam blower was turned on full, and the pressure continued to rise. It rose to 120psi which fails the test because the safety valves should have released enough steam to keep the boiler pressure at 100 psi or 110psi maximum.. Some adjustments to the safety valves did not fix the problem.

Some machining will be required to fix the valves, but after consideration I have ordered brand new safety valves and the test will be re-done when the new ones are fitted.

The boiler inspector was quite particular and proper, and very helpful. I am grateful that this safety issue was detected, and I totally agree that it has to be fixed. Thinking back to my problem of about 1 month ago, when I “dropped the fire”, (see “Holes in Swiss Cheese) I now believe that the problem was partly caused by the inadequate safety valves.

Add one more hole to the Swiss Cheese theory of disasters.

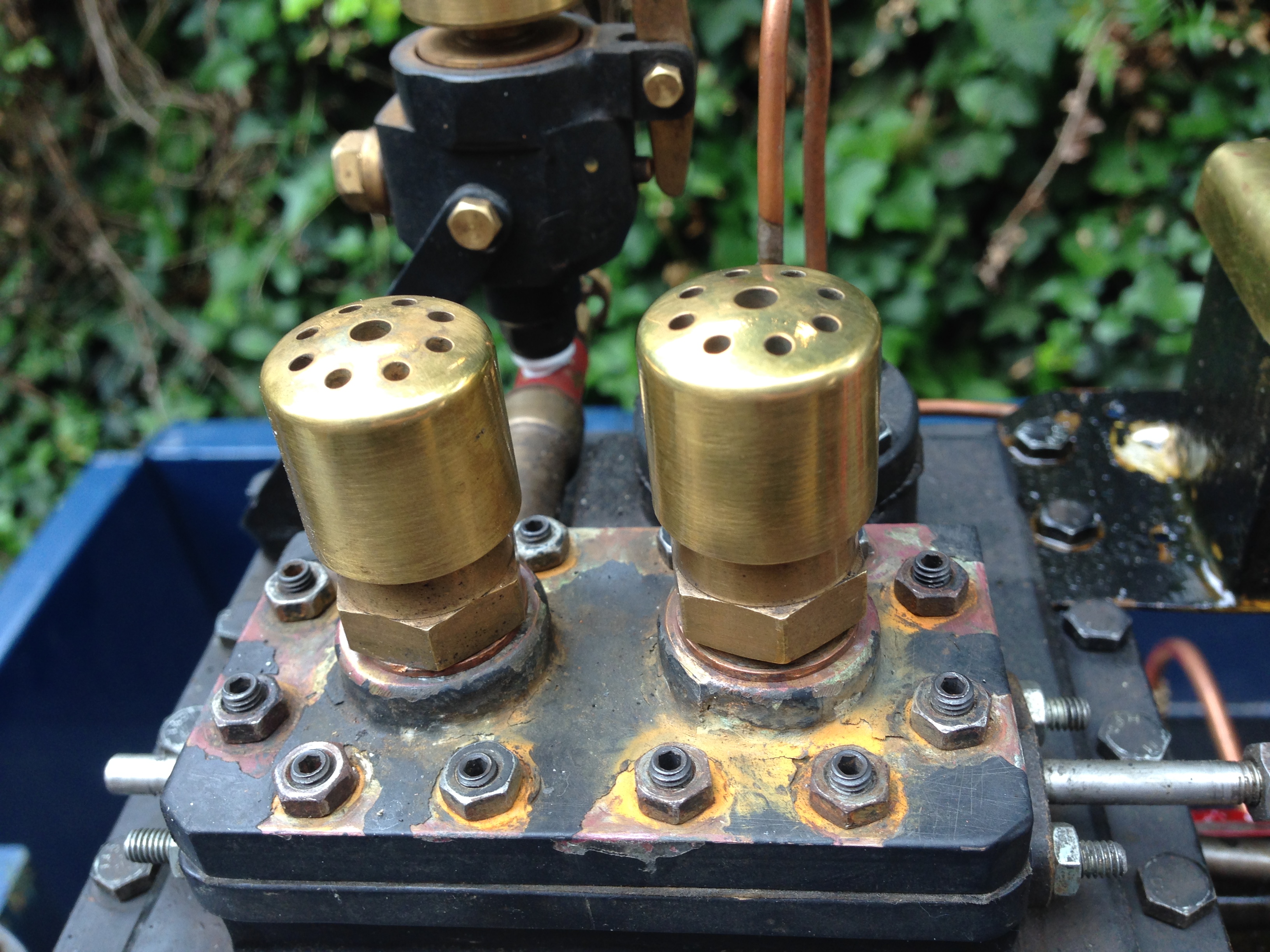

The inadequate safety valves.

The safety valves AND the oiler were replaced.

The new safety valves arrived today. Warrick Sandberg valves. I will install them later this week, and fire up the Fowler R3.

The old safety valves. Not up to the job.

The new safety valves. about the same dimensions but the exit holes are bigger and the spring tension is adjustable and lockable.

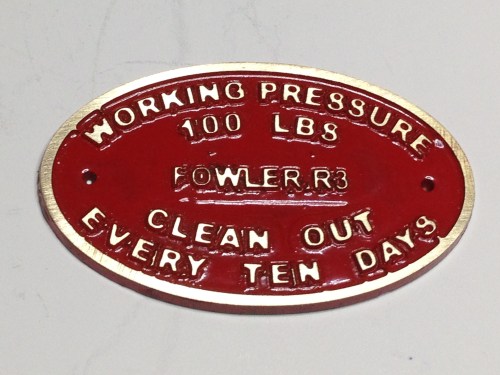

And another thing. I noticed this label near the pressure gauge of the full size Fowler R3.

So I made this one today. Slightly modified the information to suit my 3″ scale Fowler.

My enamelling technique could improve, but it will do.

Yup, better new safety valves than a boiler bursting and if you had a thorough boiler inspector who was also helpful it’s a win.

LikeLiked by 1 person

definitely! on both accounts.

LikeLike

Rust isn’t the only reason the tubes of a boiler become thin – erosion plays a big part as well (where the boiler is heavily used).

Interestingly, and somewhat counterintuitively, the boiler becomes more efficient with age. As the pipes become thinner, they become better and better at heat exchange. Right up to the point that they burst that is!

LikeLiked by 1 person

erosion? as in physically being worn away?

LikeLike

which reminds me Stuart… can we book you for a talk on “marine steam turbines” or “being a naval marine engineer” or something on similar lines? 4th Wed evening, Nov or Jan are available……

LikeLike

Hello,

I have recently got my father in law’s 3″ Fowler compound showmans and I too am not happy with the safety valves, they explode open quite suddenly and do not shut, taking a lot of boiler water with it. The engine was built to scale from the original engine so had balanced Ramsbottom type valves not Ross pops like yours. It doesn’t rise in pressure but carries too much water and seems unable to shut itself off. I think the safety valves are under sized. Did you purchase the new ones you made or built them to someone’s drawings or your own? Would you be able to provide the sizes as they clearly do the job perfectly and I would like to copy their sizes.

Key things I need to know if you are able to tell me; what size hex is the body made from (space on top of the cylinder block is limited!), what is the valve seat and ball size and what are the steam vent hole sizes at the top please?

Many thanks for your help!

Steve

LikeLike

Hi Steve, I don’t recall the ball, hole, dimensions etc, but my new “pop” valves were purchased from Warrick Sandberg as mentioned in “The Boiler Inspector” post from 2017. Warrick has a web site which you can find with a Google search. His valves, which he makes himself, are about the same size as the ones made to the original Paslow plans for the 3″ Fowler compound. They have never given me any problems, and the boiler inspector was very happy with them, including the recertification testing in 2023.

I would be interested to see some photos of your Fowler Showman. John.

LikeLike

Hi John

I still follow all your posts great work keep it going.

Steve Newell was asking about safety valves if he wants to build his own I have plans for the pop style I used on my boiler build and I have s/steel balls and s/steel springs as I purchased 100 of each when I built my boiler, My safety valve still operates great.

Cheers

John

LikeLike