Just for the Record

I am back. Looking at my photos over the past month or more, not much of interest to my regular readers. In fact, very little time spent in the workshop. I have been chauffeur for SWMBO, to and from hospital and medical appointments. Buying groceries. Cooking. Infrequent visits to GSMEE.

But, there was one day in Melbourne where I had a couple of spare hours, so I visited a cannon which has been on my bucket list for several years. Two cannons actually, but virtually identical.

High St, Northcote, Melbourne, (Victoria, Australia for my OS readers).

2 breech loader, rifled (of course), Armstrong cannons, of 1885 vintage.

And on the other side of High St is another gun of the same type. It is 5.88m/ 19′ long….

…and has an 8″ /203mm rifled bore. The bore serves as a rubbish bin for the local morons.

My artillery references categorise these guns as Armstrong pattern, breech loaders, of approximately 1885 vintage.

The Northcote guns have carriages which are naval types, and were possibly originally mounted on the gunboats HMVS Albert and HMVS Victoria. The barrels are the same as others which were originally mounted as garrison guns at South Channel Fort, Port Phillip Bay, Victoria. The Northcote barrel trunnions are covered, but said to be numbers 4312 and 4266. There is no barrel weight visible but these guns typically weighed just under 12 tons each. The slides are missing, but would have been pivoted at the front end.

The large breech mechanism is missing smaller removable components but is still impressive. The diameter of the breech is 918mm.

Said to have a range of 7500m. Projectile weight 95kg / 210lb

So. Will I model these guns? Without plans or good photographs of intact carriage and slide, probably not. But if I can locate such details……??

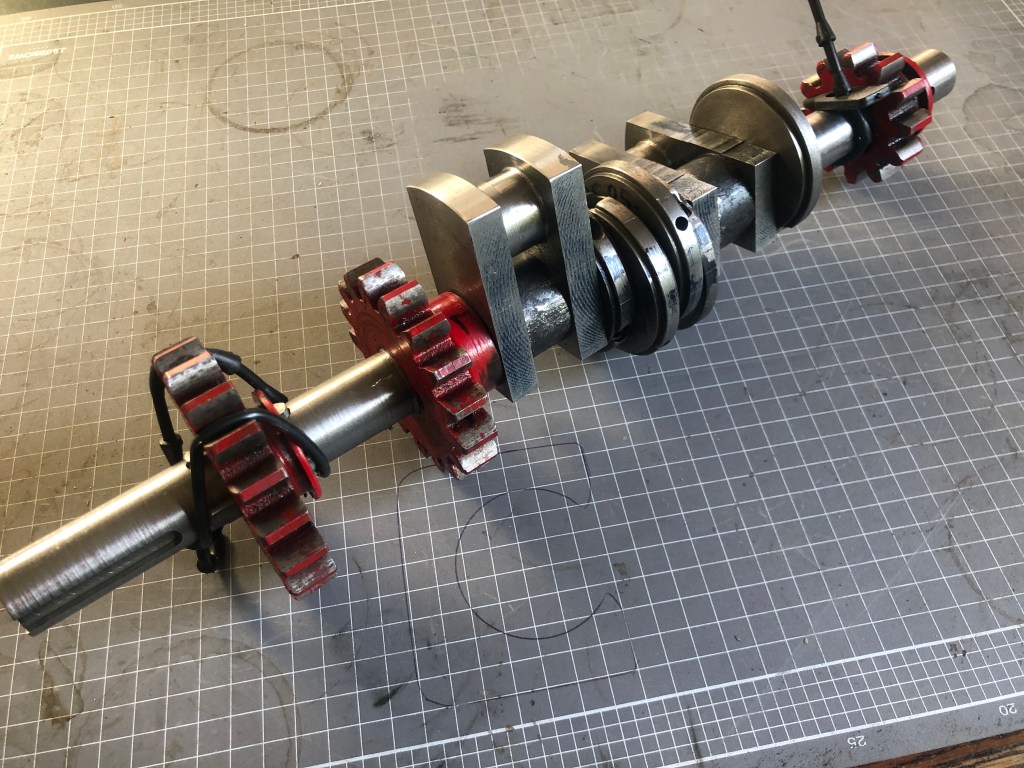

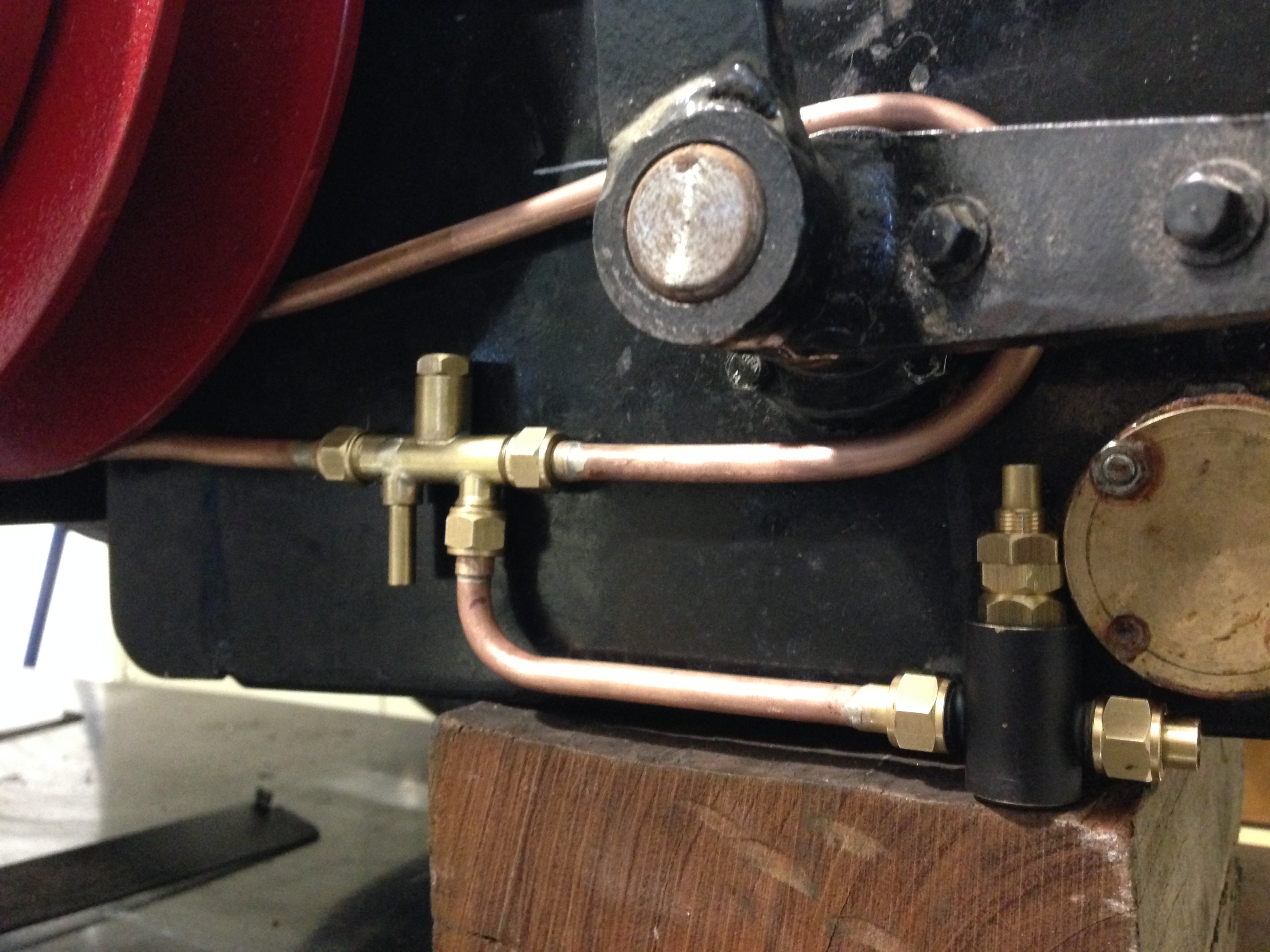

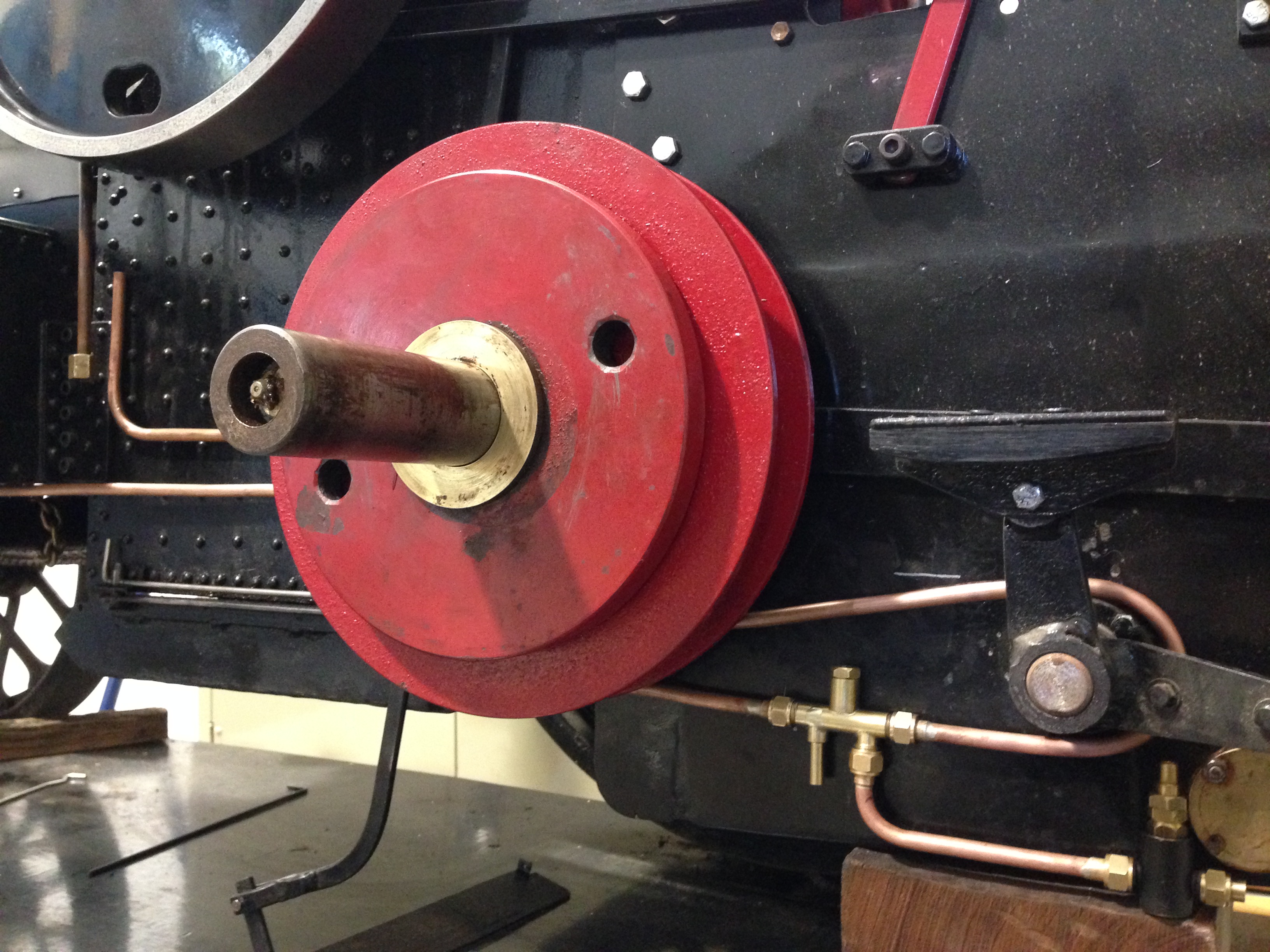

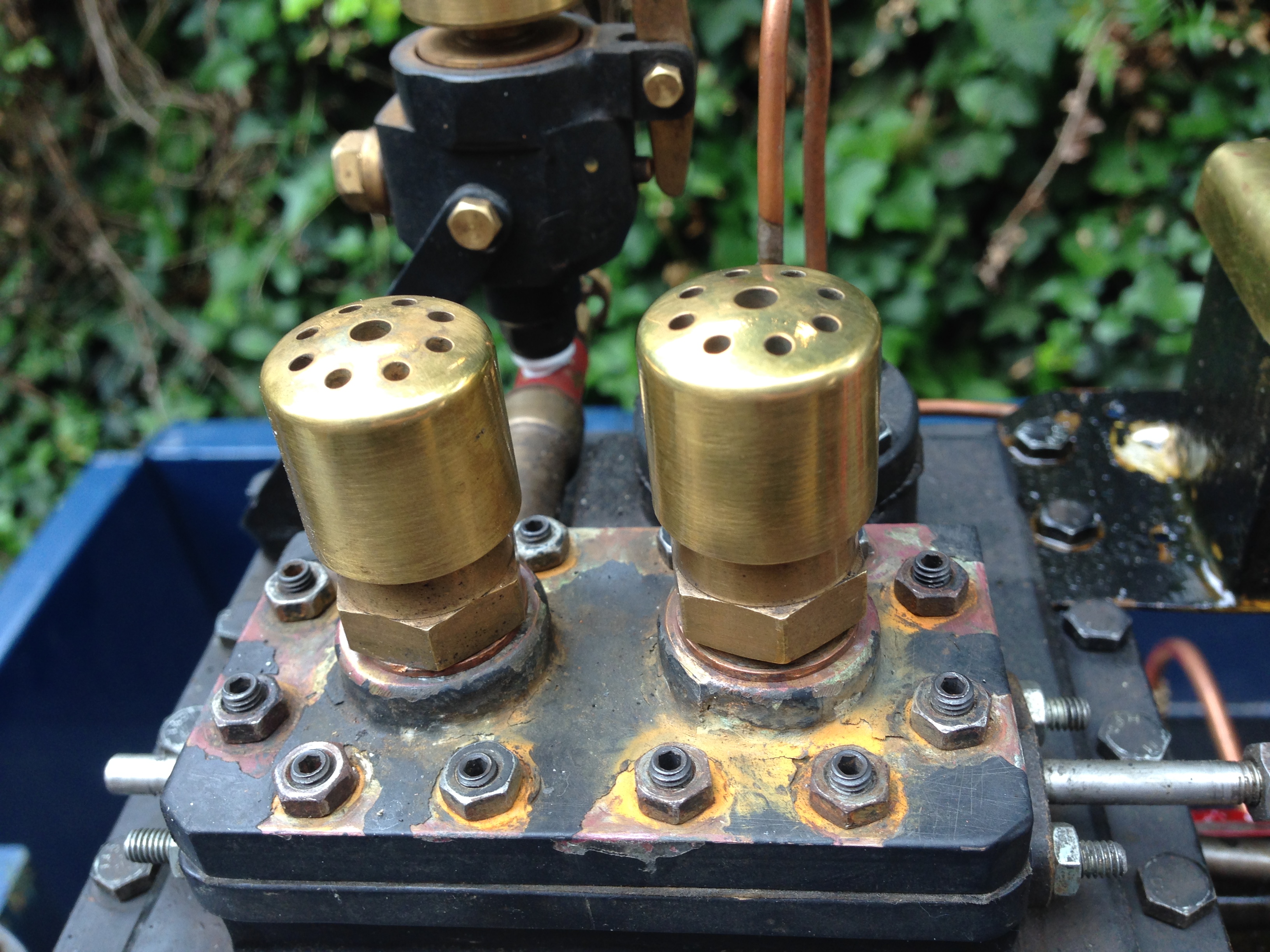

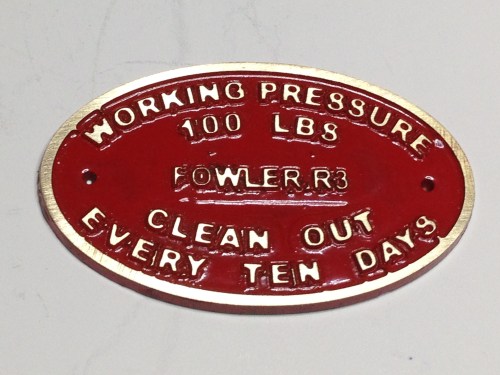

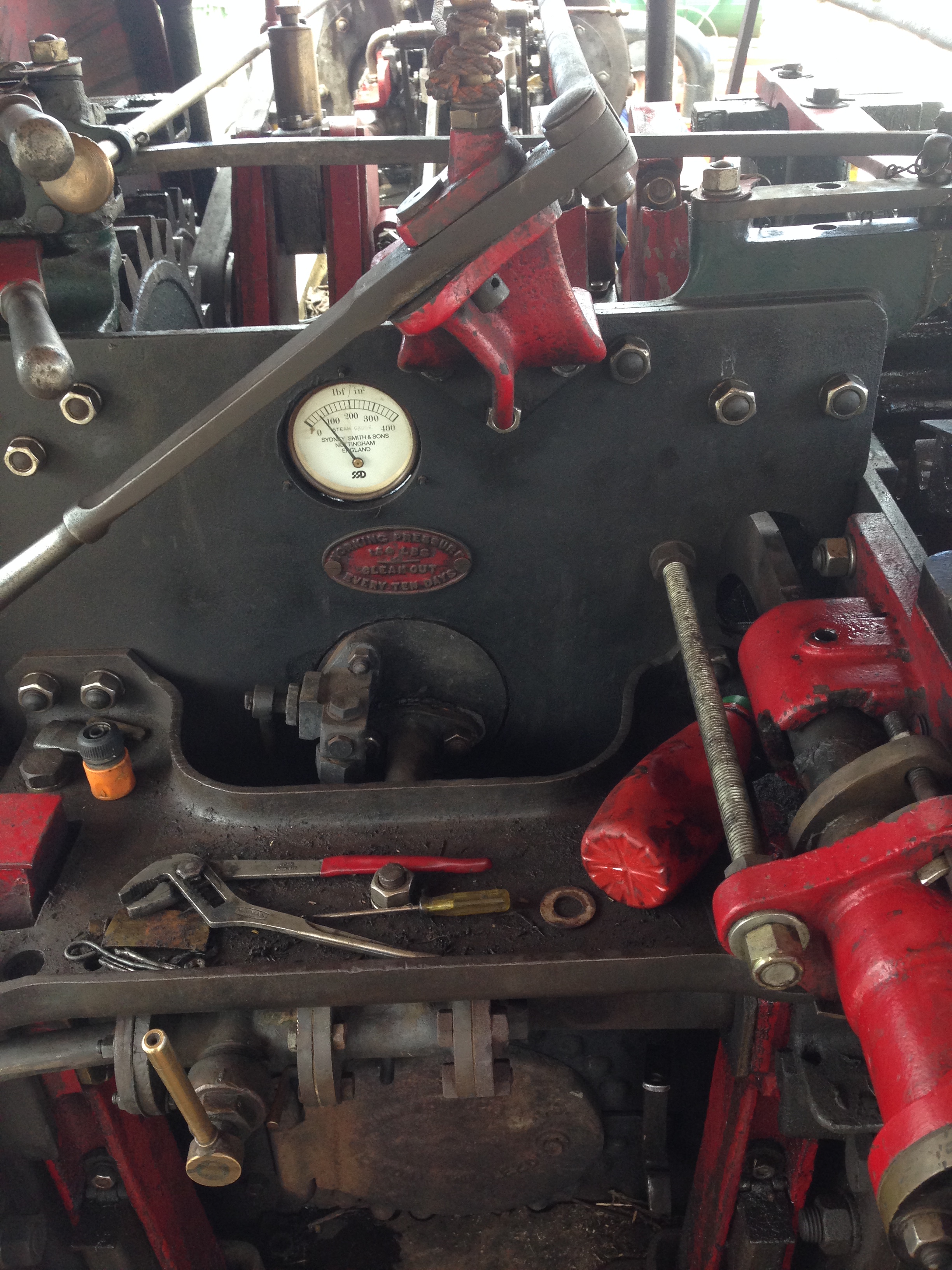

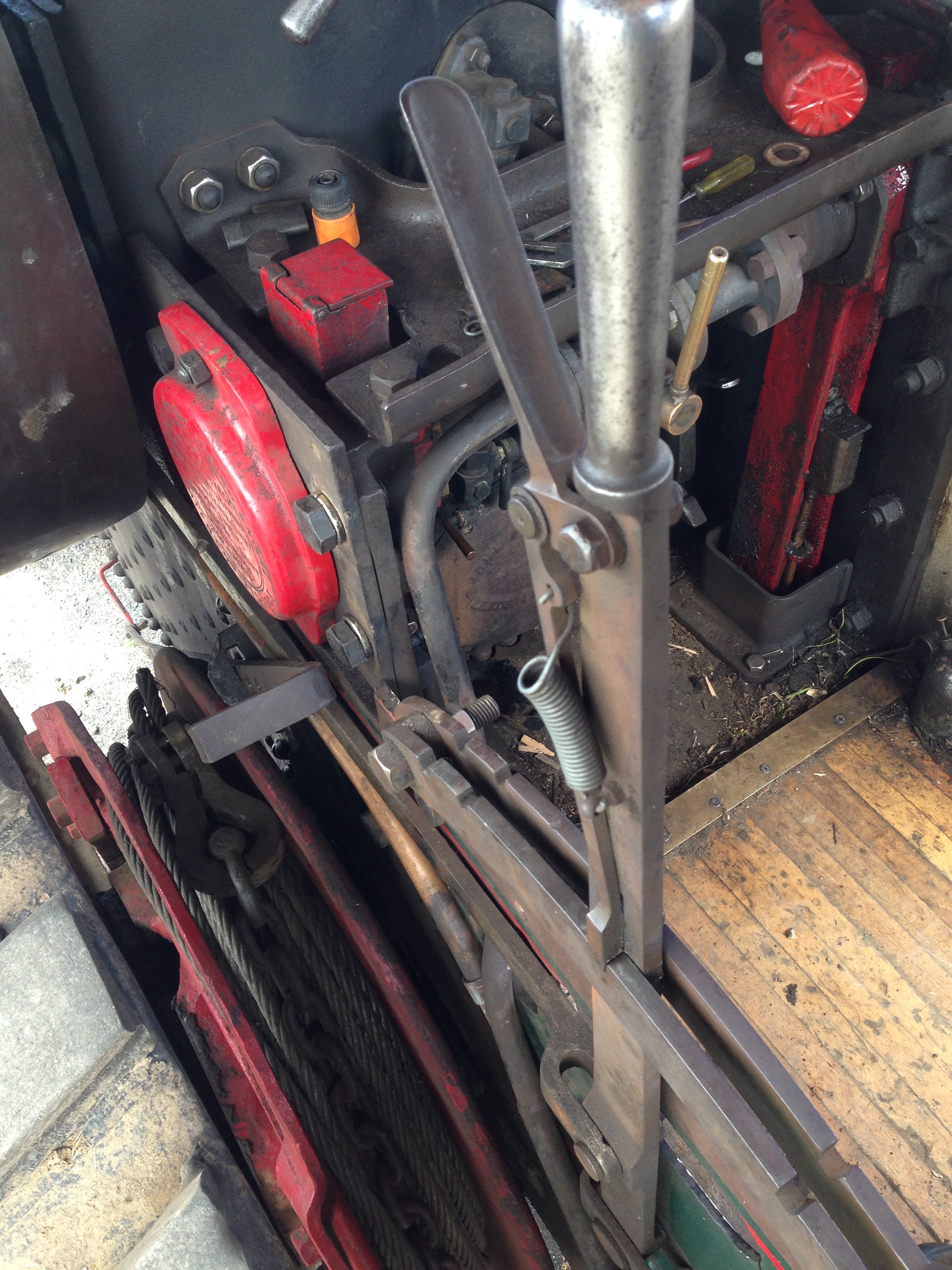

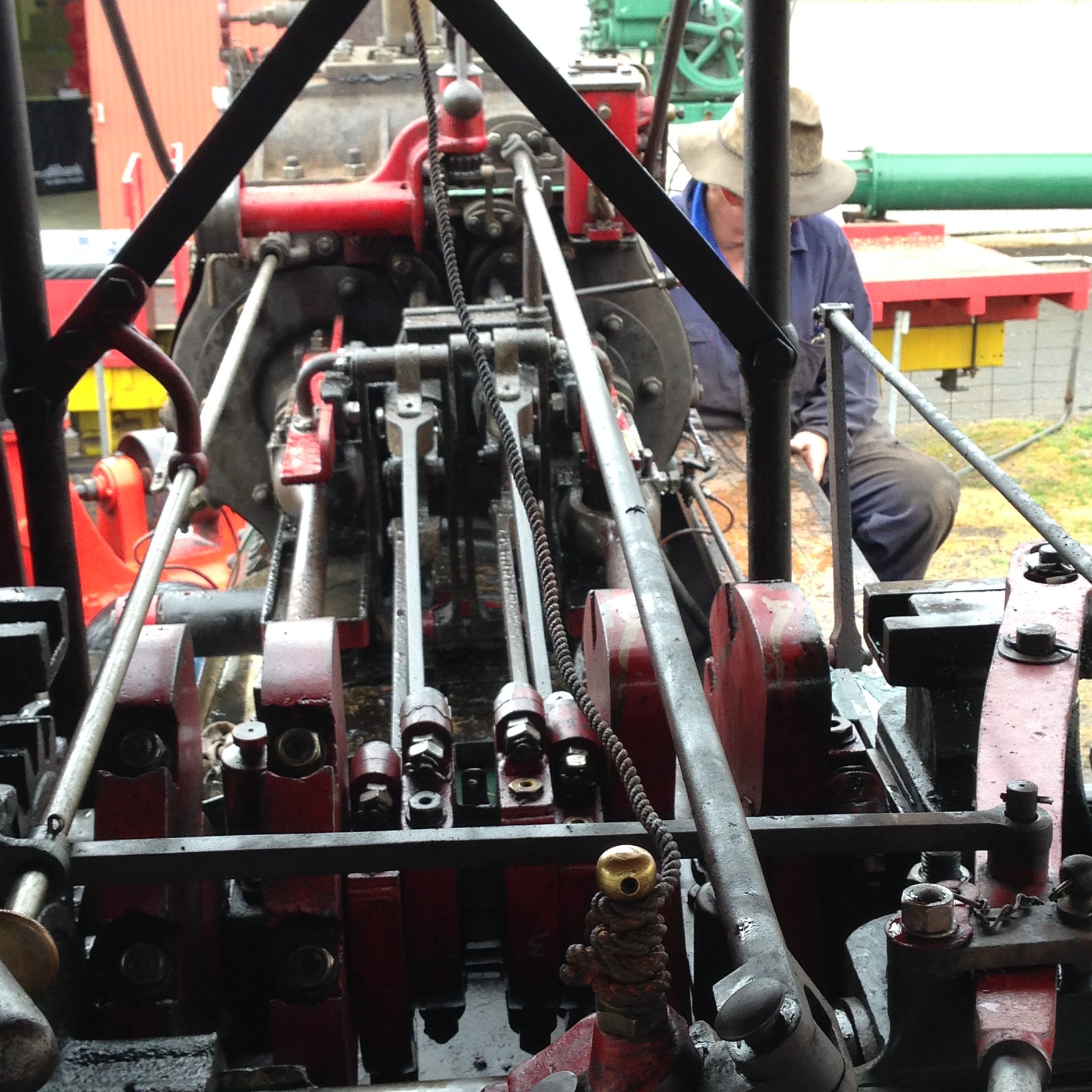

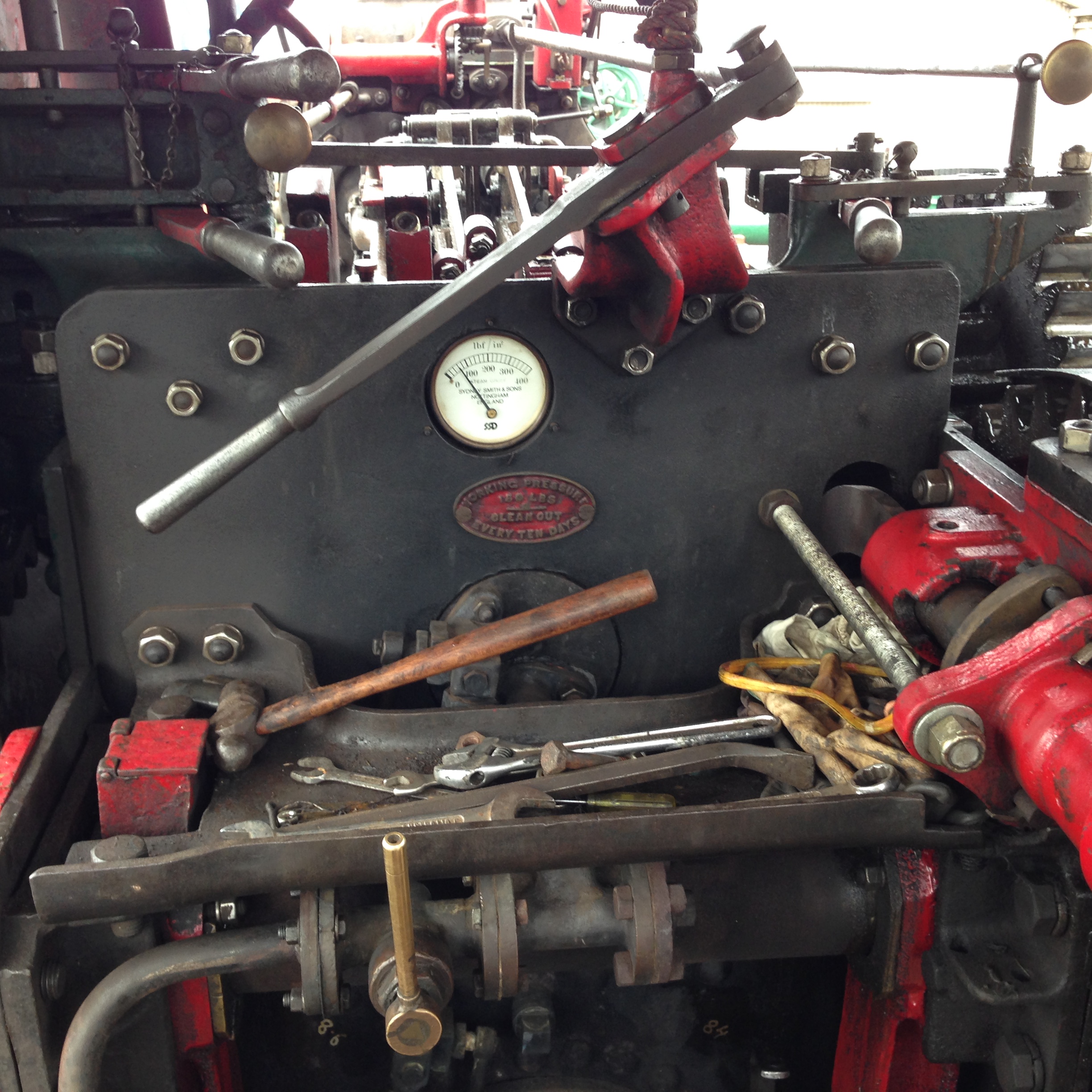

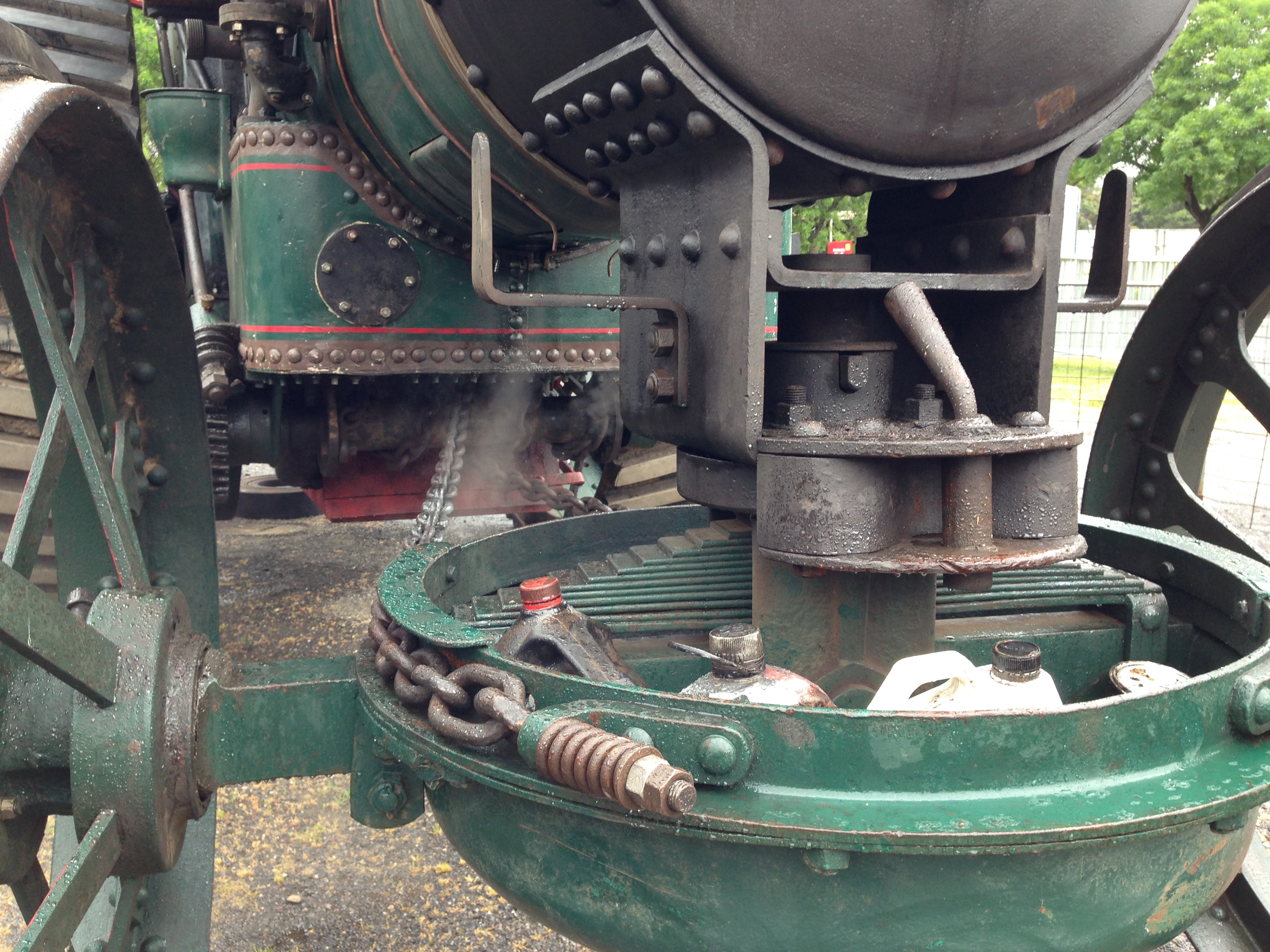

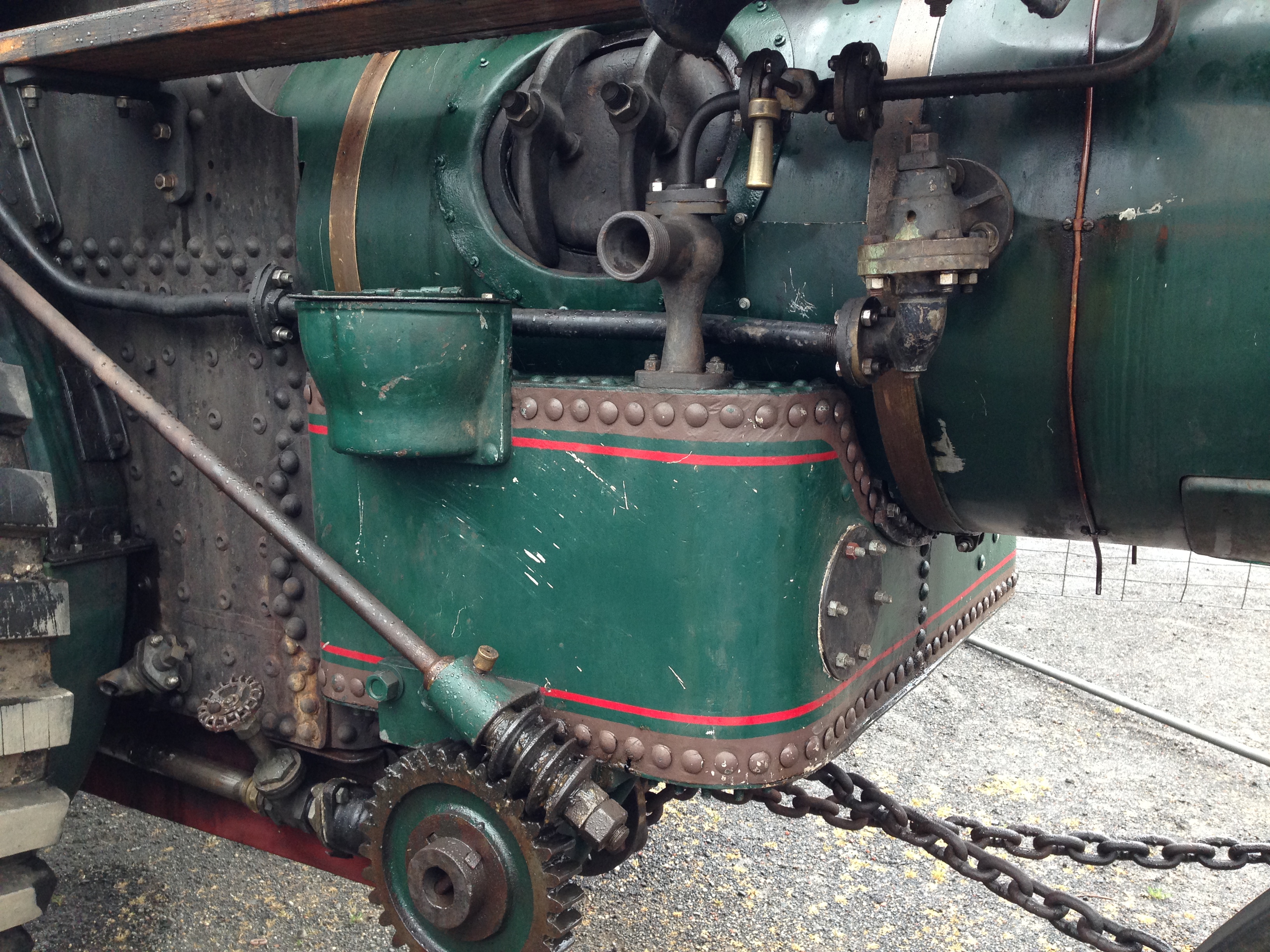

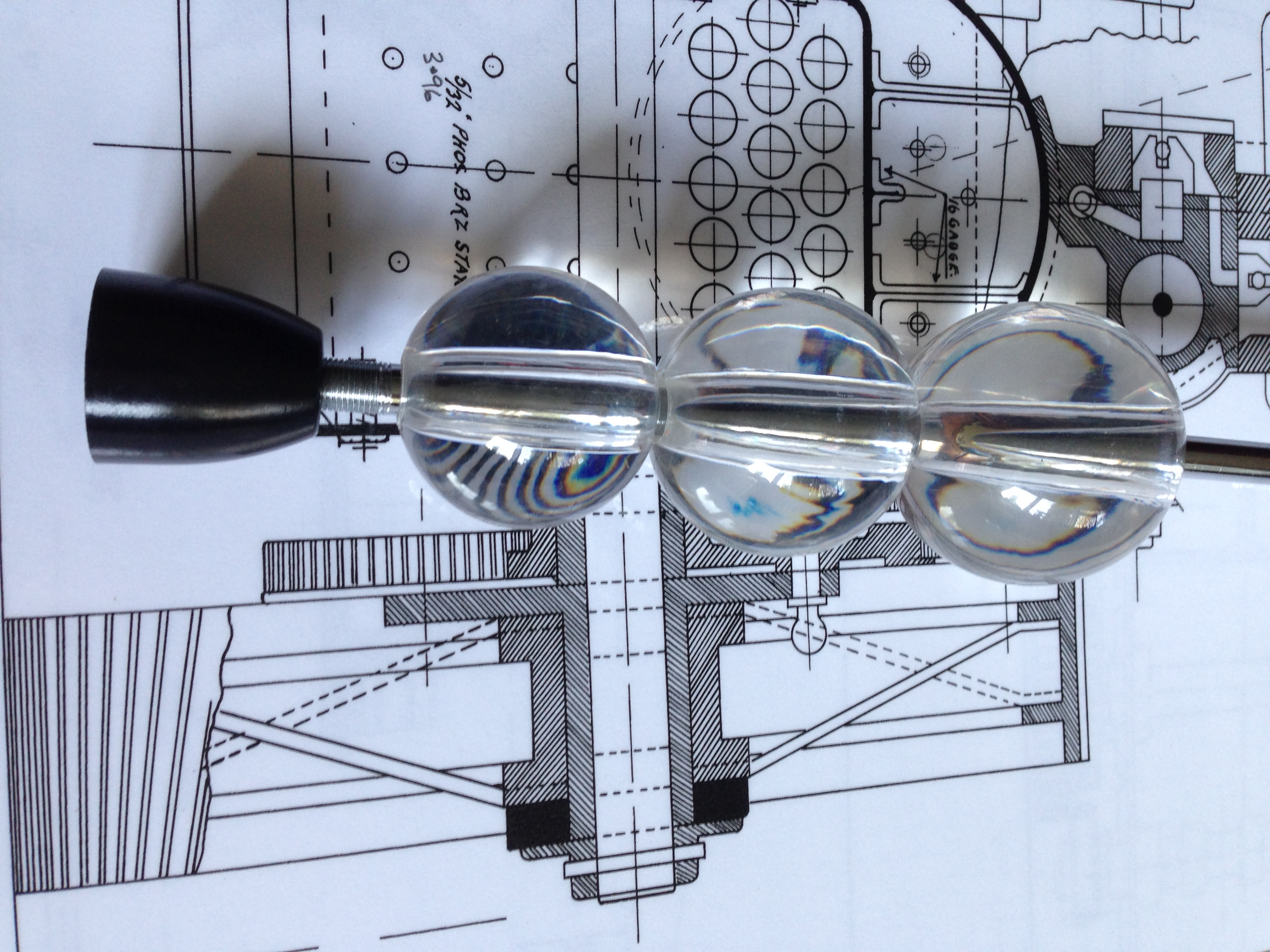

BTW. I have decided to sell my 3″ Fowler traction engine, tender, and coal, on a fitted 6’x4′ trailer with winch, toolbox and ramps. Full construction plans. It is running nicely with its new crankshaft, and has had boiler certification recently renewed until 2027. It has various improvements since this photo was taken, including working steam winch, steam injector, steam driven water pickup, new mechanical oiler, relocated hand pump, and more. Best offer around $AUD20k. Please, no tyre kickers. See previous posts for more pictures and videos. Inspection at Geelong, Victoria.