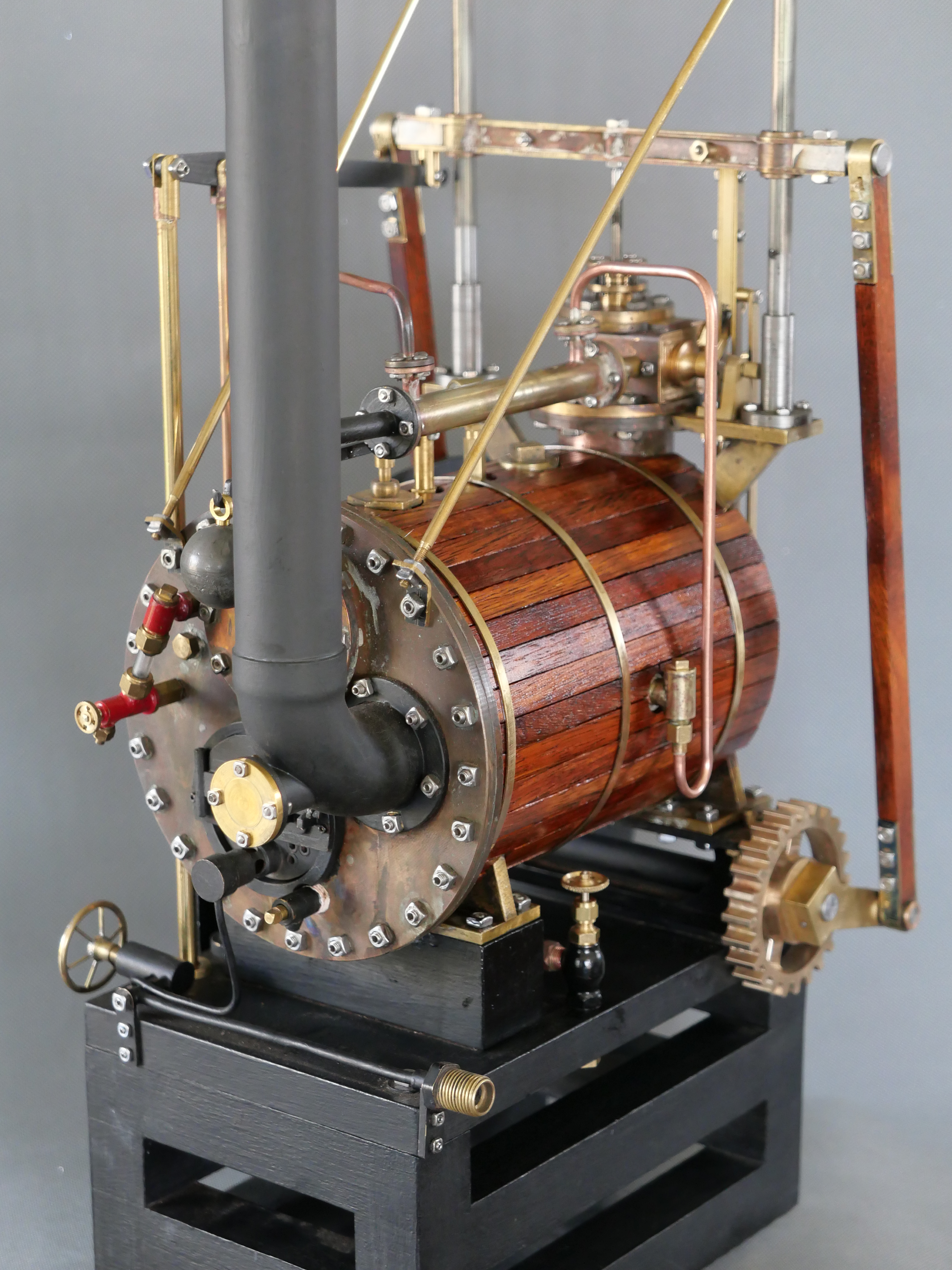

Back to the Trevithick Dredger Engine Model – the lagging.

by John

The only surviving Trevithick dredger engine, in the London Science Museum, shows no signs of ever having been lagged. I know this, because I examined it closely, recently, during my UK trip.

No lagging, no marks in the paintwork, which would indicate wooden lagging strips ever having been attached.

But, we know that Trevithick readily adopted ANY improvements to his designs, and lagging was appearing on engines at about the epoch of the dredger engine design. Plus, his engines were in use as late as mid 19th century, and lagging was well established as a normal feature by that time.

And, my model definitely needs some efficiency improvement. Using a 40kW burner to power an engine of this size is ridiculous. So I Have added some lagging.

Equipment for applying lagging, from the left… scroll saw, super glue (I used 6 tubes), strips of wood (in this case, Australian Jarrah, grinder for shaping, Dremel for shaping, good light, and the engine with some of the strips glued in place.

I used about 48 strips of wood with some spares. These were cut and sanded in advance. 5mm x12mm x 130mm.

The Super glue is used to hold the wood strips in place temporarily, until the brass boiler bands are installed.

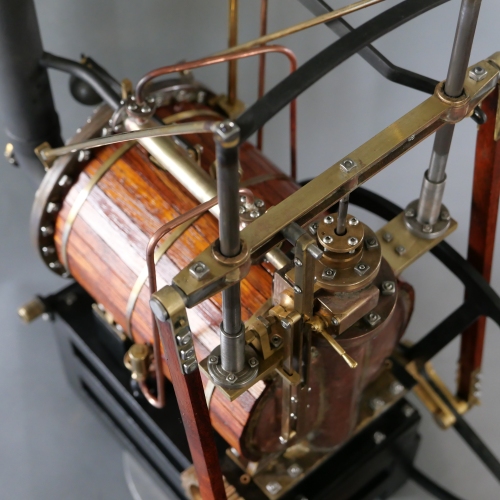

I started at the top, and worked my way down on both sides. Most effort is made in fitting around pipes and boiler bosses. Unsatisfactory strips are levered off and scrapped.

A rebate was milled on every wood strip, to permit removal or tightening of the boiler end plate nuts.

I used rubber tree ties to maintain pressure until the glue dried, but in most cases I just applied finger pressure until the wood stuck fast.

Some pipes and fittings necessitated grooves being made with round files.

Super glue does not provide a permanent bond to copper for some reason. And it certainly will not survive the heat from steaming. But it is fine for a quick and temporary bond.

After making and applying the brass boiler bands (this was covered in the “6”vertical boiler” posts) I used olive oil to seal the wood. See discussion which follows.

I chose olive oil to seal the grain openings of the jarrah. I know from previous firings that the temperature of the boiler shell does not exceed 100ºc. Olive oil will not smoke or flame until the temperature exceeds 200ºc, which is higher than any other common oil. Also, as a failed olive farmer, I have plenty of old olive oil. At worst, my engine steamings might smell like a fish and chip shop. And refreshing the oily surface will be quick, cheap and easy. And the olive oil will not form a skin which might peel or flake. Anyway, this is “model and experimental” engineering. If it does not work, I will make some new lagging, alright!.

And I took some more photos with my Panasonic Lumix 100-2 camera…….

Still some more painting required to the end plate, and some fittings.

That domed boiler end with the cylinder protrusion also needs some paint. But the lagging looks good hey?

Even SWMBO has relented… “It can go with the other engines”. It will, when it is finished. Still requires more painting.

Good bold step John. I’m sure Trevithic would have approved as he never stood still.

Was there room for insulation under the timber laging?

I’ve used super glue as pins to hold things too while the other glues set.

Looks really good too John.

Tim

LikeLike

Thanks Tim. No room for extra insulation. I feel comfortable with this leap too. John

LikeLike

Looks very nice John. And indeed Trevitic could also appreciate it.

Nice to have you back in the workshop again after your trip to the UK..

It was nice to look over your sholder to the great musea that you visited.

LikeLike

It is good to hear from you again Huib.

LikeLike

This is the second time I reply John, the firts time they did’nt place is why ?

Glad you are back in the workshop after your trip to the UK, is was very nice to look over your shoulder to the great Musea you visit.

It must be a great experiance for you to visit all these.

About the lagging, it looks nice an Trevithic will aprove it I think.

If it will help to hold the temperture ?? I hope for you,

Without insulation I think the wood only is not enough but we will see.

LikeLike

Yes. We will see about the function of the dredger engine. I do not know why some replies do not come through. But please continue to reply. Your replies give me encouragement and are very much appreciated. John

LikeLike