Boxford CNC lathe (5)

by John

The following pictures and video were supplied to me by Stuart Tankard.

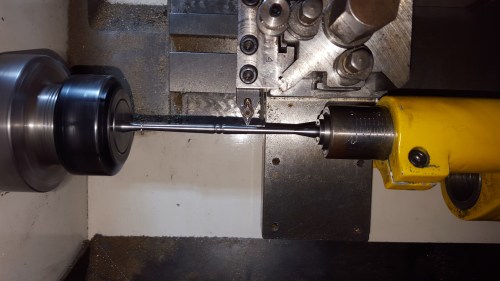

They show the rarely used tailstock in use, supporting a relatively long thin workpiece.

The lathe is Stuart’s, and his control panel is fixed to the lathe cabinet. (Mine is an identical machine except that I use a wireless MPG).

The tailstock is the part coloured bright yellow, and it normally sits unused in a drawer, or hinged down and out of the way. As you can see however, it occasionally is useful.

Stuart’s lathe. Note that the G code for the part was generated by a program called EZILATHE. I also use this very handy program. Ezilathe is a free download.

The part is the first step in making a link for the beam engine which Stuart is completing. The headstock end is held in an ER collet. The tailstock contains a small roller bearing held in a shop made fitting. After turning, the tear drop ends will have flats milled onto the sides, then holes drilled and reamed for shafts.

Check out the following Youtube video to see Stuarts lathe in action.

Very nice. Would not the original have been turned between centers so the end would have a center cut in it even if it might be filled up afterwards?

john f

LikeLike

I guess so. That is the method I used on my beam engine. But it is nicer to not have centering holes to fill in.

LikeLike

Hi I wonder if you can help, I’m refitting a boxford with the same gemini controller. I’ve spent hours searching for documentation on the gemini with very limited, and contradictory results. You mention that you have documentation for the drive and I wonder if you could share it with me?

As ever Chris

LikeLiked by 1 person

HiChris, that was 7 years ago, and surprisingly I still have the documentation, and the controller itself which I ended up replacing. I will need an email address to send the pdf file. You can have the controller too if you wish, for the cost of the postage, or free pickup from Geelong.

LikeLike

Hi John,

I too rareley throw things away in the hope that they will come in handy! I am slated to visit my sister in adelaide one day so perhaps Ill swing by yours whilst there. My address is … not uk or anything else. I saw on your blog that you use the lathe. I bought a 240TCL which came with the pc and software so I can use it in a rudimentary fashion. It has a vfd and big motor which should conevert quite easily. I also got a 250 VMC (mill) which didnt come with software so Ive replaced the stepper drivers and power5 supply and fitted a DDC expert which is a standalone controller which seems to be very capable (well the axis are all working and it supplies an on off to a relay and 0-10v but whilst the motor turns on and off it’s not controlled but seems to hunt at high speed causing the big inductor to thump as the speed rises and then falls.Most peculiar. I’m surprised how little information there is for these machines as what you and I have experienced rebuilding them is not an uncommon tail.

Thanks in advance for the files and keep up the good work

As ever chris

LikeLike

See emails. You will notice that I have deleted your details for privacy. John

LikeLike