Lathe Toolpost Milling attachment (CNC)

by John

Although my recent posts indicate that I have spent a fair amount of time recently on Google Earth Pro, I have also been busy in the workshop. Mainly finishing the toolpost milling attachment for the Boxford CNC lathe, but also fiddling with the laser attachment for the CNC mill. Neither of those projects is completely finished, but I thought that you might be interested in some progress photos.

This is what the Boxford TCL125 CNC lathe now looks like from the front. It is substantially modified from the original which I purchased 5 years ago. To mention a few changes…..

the axis stepper motors are bigger and more powerful than the originals

the ball screws are now 10mm diameter, compared with the original 8mm

there are some adjustable axis limit switches

the 3 jaw chuck is replaced by an ER32 collet chuck

there is a removable toolpost milling attachment with ER 16 Collet chuck, with a speed controller, cables, and panic switch.

there is a removable safety screen (not seen in the photo)

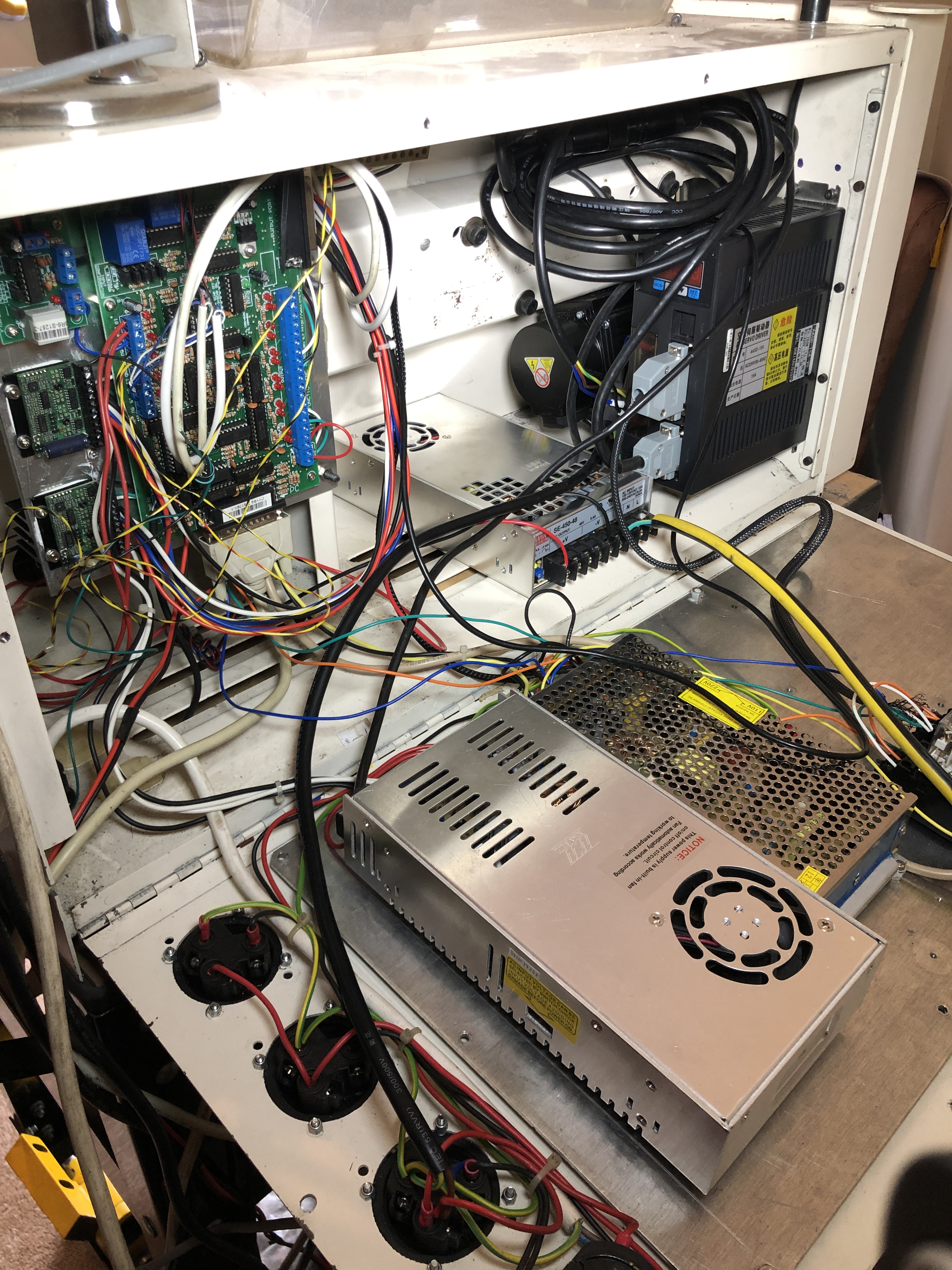

And hidden in the electronics compartment….

There is a 750 watt AC Servo spindle motor and controller (RHS, under the coiled cable)

The electronics have been replaced with a Mach3 compatible breakout board and associated peripherals. Anyone with an original 1985 machine will hardly recognise these components.

And the software is now Mach3, running off an old Windows XP computer. And using “Ezilathe” for most of the G coding, especially threading, and interpreting shapes which have been drawn as CAD dxf’s.

The new toolpost spindle works, but the software needs a bit more fiddling to tie it into the CNC controls of the lathe.

The Boxford has provided an excellent base on which to make these changes, and I look forward to producing some videos soon of the renewed machine in action.

Nice job 🙂 — I have just started a similar project, I except I will be using Linuxcnc and driving that with a mesa card (I have a tool changer and need extra I/O)

I am procrastinating as what to do with the spindle motor, I have some spindle motors but they are either too big or too small ………

LikeLike

Sounds interesting. I have no experience with Linux. Is the lathe a Boxford?

LikeLike

I have two I am working on one is a ORAC and the other is the TCL 125 they are very similar

LikeLike

Hello there John, I’m restoring a TCL 125 that has had… a rough life to say the least. You seem to have made an internet niche as the single greatest source of media for this little known lathe. I’m missing a cross slide leadscrew nut as well as any evidence of a limit switch on either axis. If you have the time it would be much appreciated if you could post how you did your larger ballscrew conversion and where the limit switches on the lathe are.

LikeLike

It seems a long time ago that I did that conversion to change the 8mm ball screw to 10mm. (purely because I could not source a new 8mm ballscrew). If it is not in the blogs I doubt that I will be much help. I removed the limit switches because they were an unnecessary complication. Never missed them. where are you located? I probably still have the original 8mm ball screws with nuts somewhere. In retrospect, I discovered that the problem was not the ballscrews condition, but they were not properly installed! I should not have changed them.

LikeLike

Ah there’s no “someone replied” alert on these comments! I’m over in sunny Sheffield, UK here. Sadly a bit of a distance. I’ve also given myself the unpleasant but not impossible task of repacking the saddle ballnut after dissasembling things a bit too much. The price difference between mass produced 1204 ballscrews vs 0801 ballscrews was an unpleasant surprise.

As for limit switches, huh! I’ve never used a CNC lathe before so I can imagine simply zeroing off of the work piece being viable but I had assumed limit switches were just an integral part of CNC life. Does save me some time and money though

LikeLike