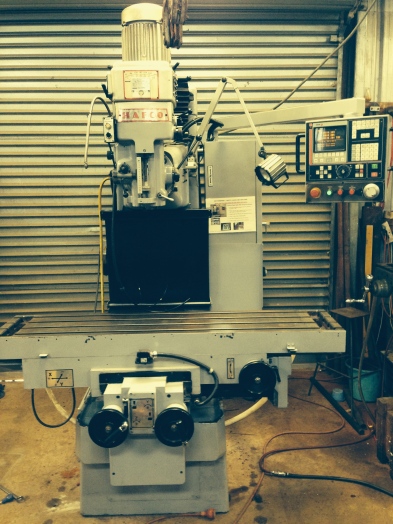

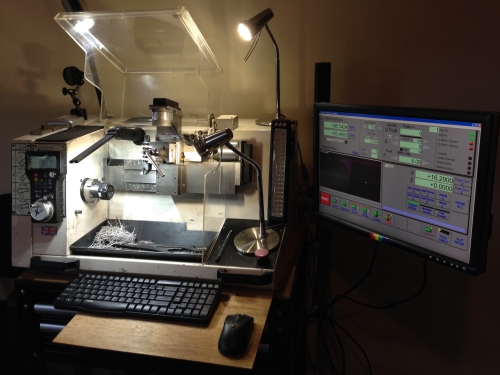

The X axis on my NC mill was always noisy in operation from the time I purchased the machine a year ago, and the seller told me that he thought the end bearing was the source of the noise.

In comparison, the Y and Z axes were almost silent in operation, swishing to their allocated positions.

But the machine worked well and accurately, so I did not fuss about the noise.

But a couple of weeks ago, the X axis low pitched rumble changed to a louder, more graunchy sound, which I did not like at all. However the accuracy was still not affected. And the noise occurred only with rapid feeds. On machining feeds, it was not noticeable.

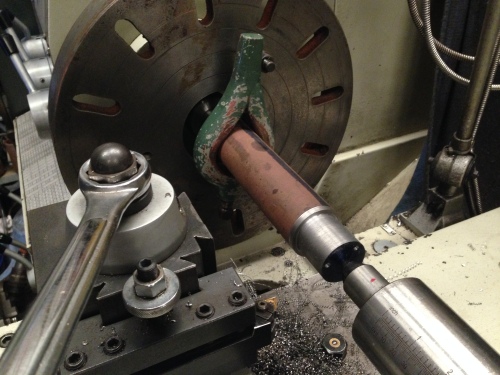

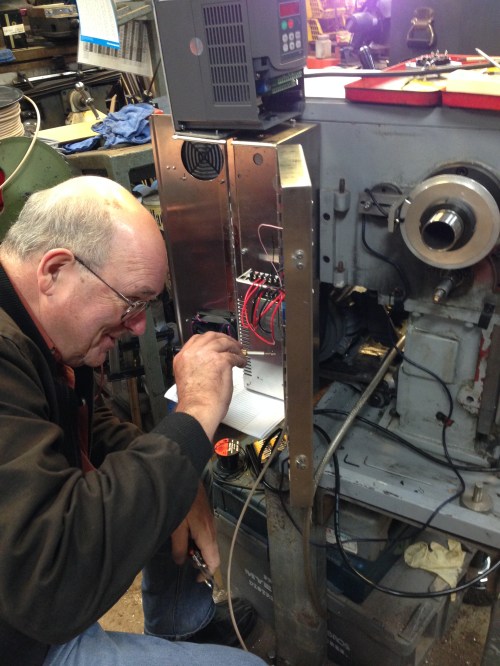

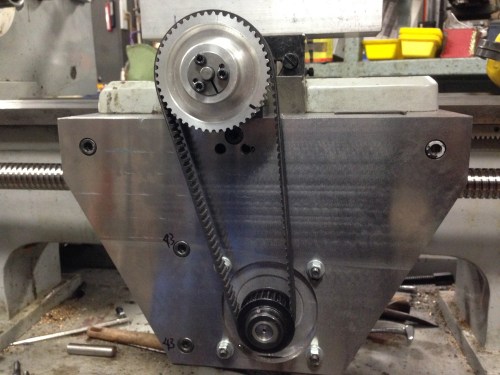

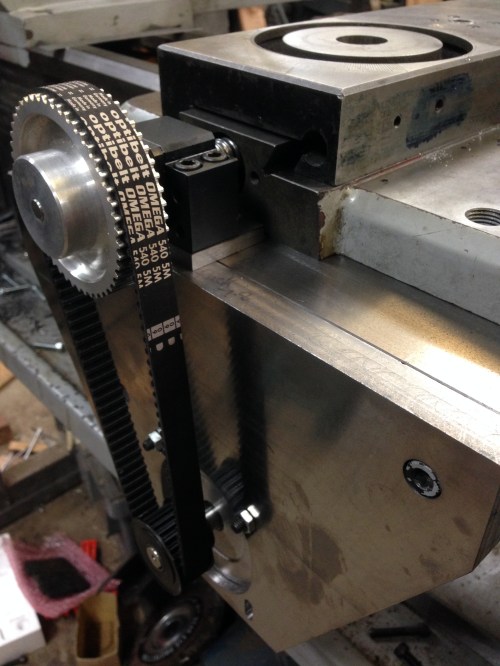

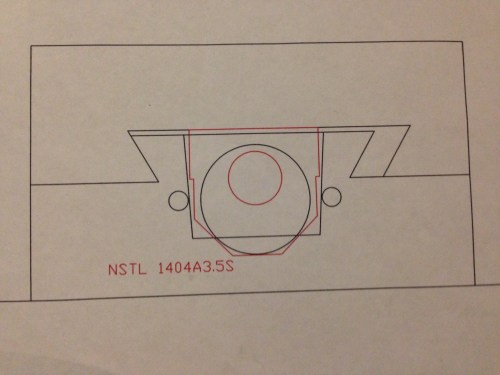

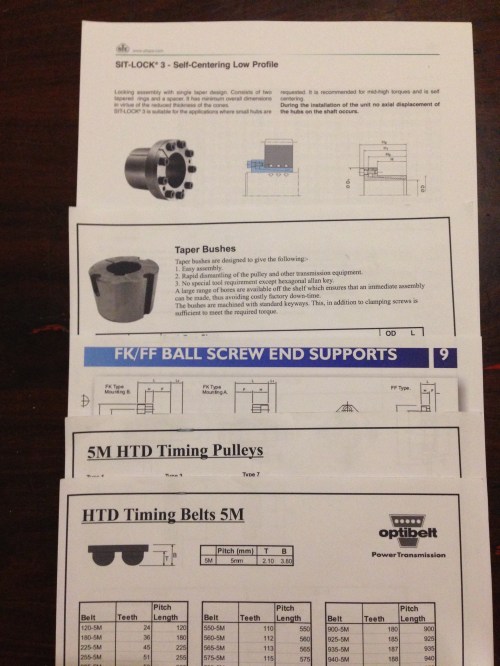

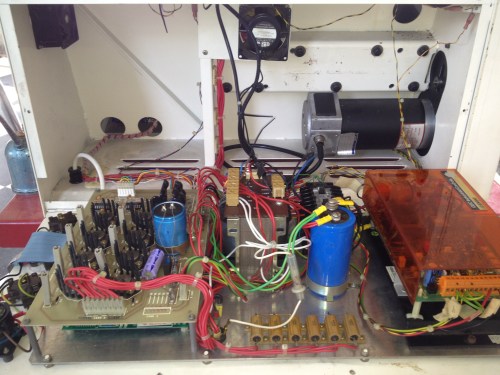

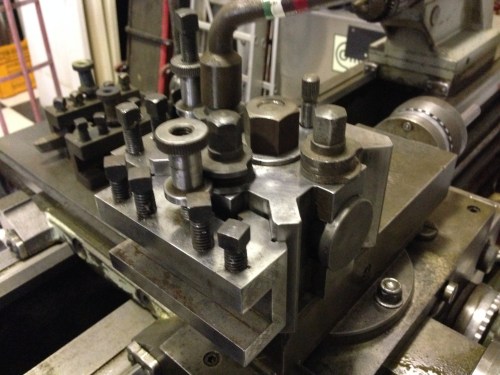

So, with some trepidation, and only a vague notion of the construction of the machine, I disassembled the suspect bearing. That involved unscrewing covers, unbolting the heavy servo motor and lifting it to the floor (not wise. my back still aches. next time I will use a supporting jack or platform), then trying to figure how to remove the toothed pulley. A phone call and text message including photo to my expert friend (thanks Stuart) gave me the necessary information how to remove the tapered bush and pulley. I made a simple gear puller which screwed into 2 threaded holes in the end of the tapered bush, and the whole lot magically came apart.

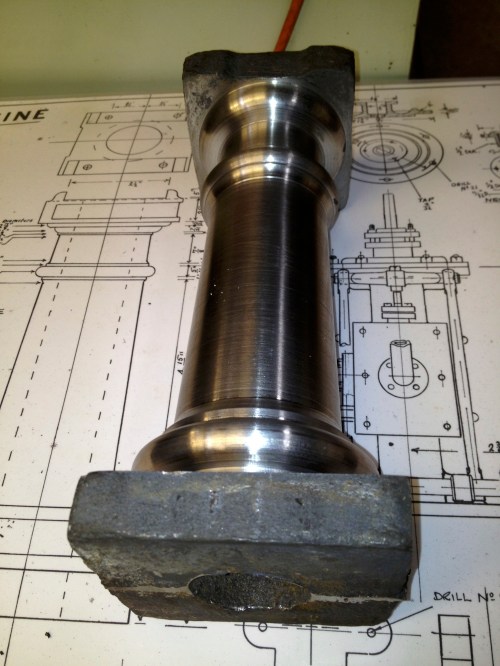

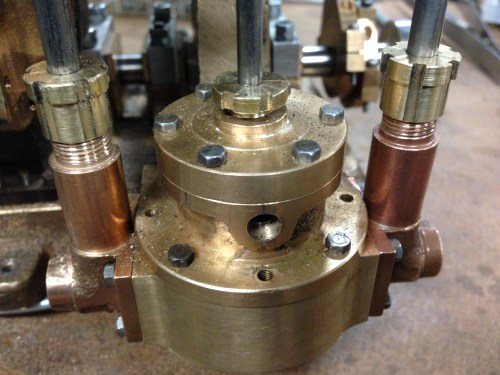

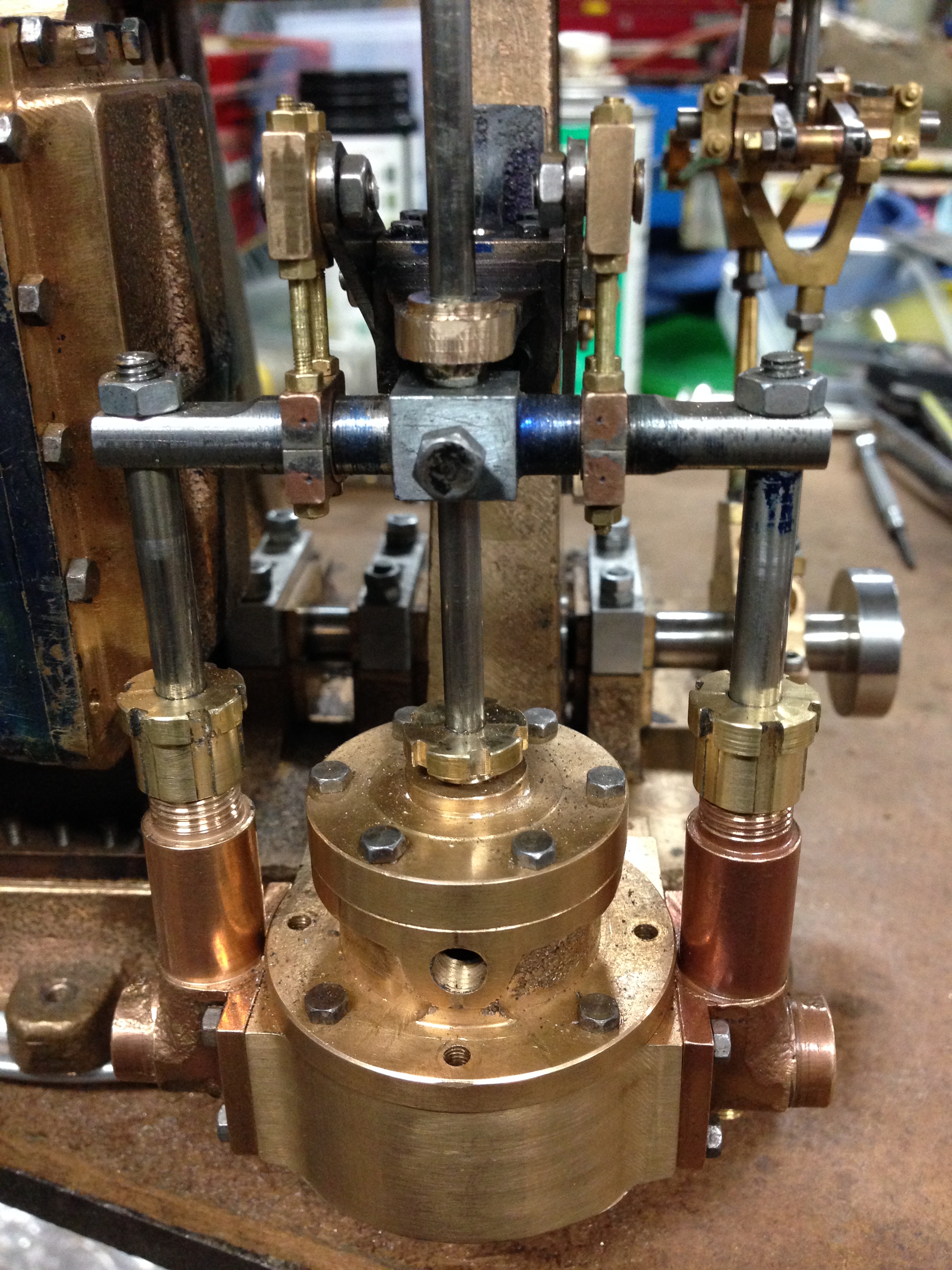

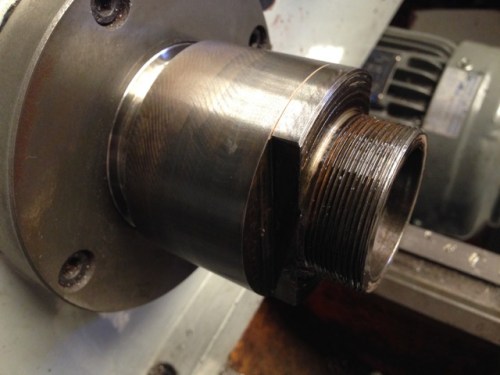

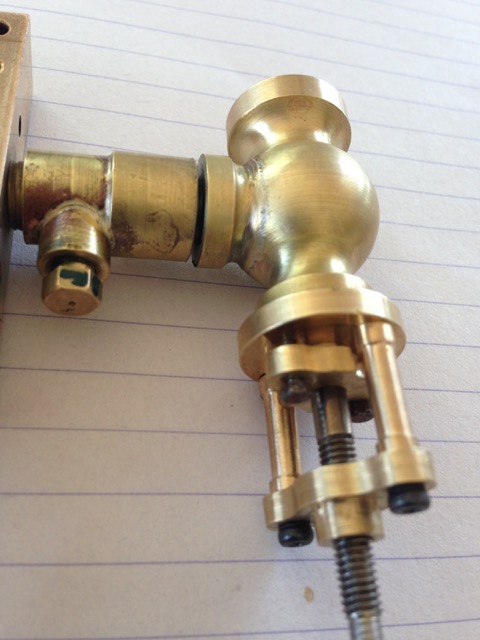

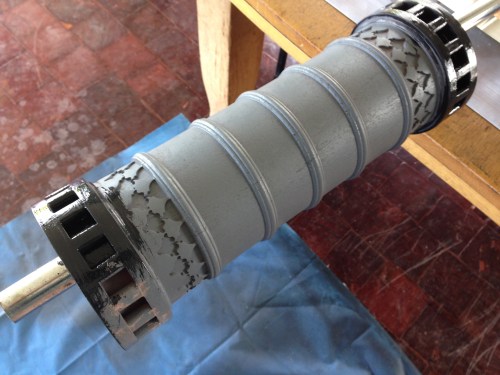

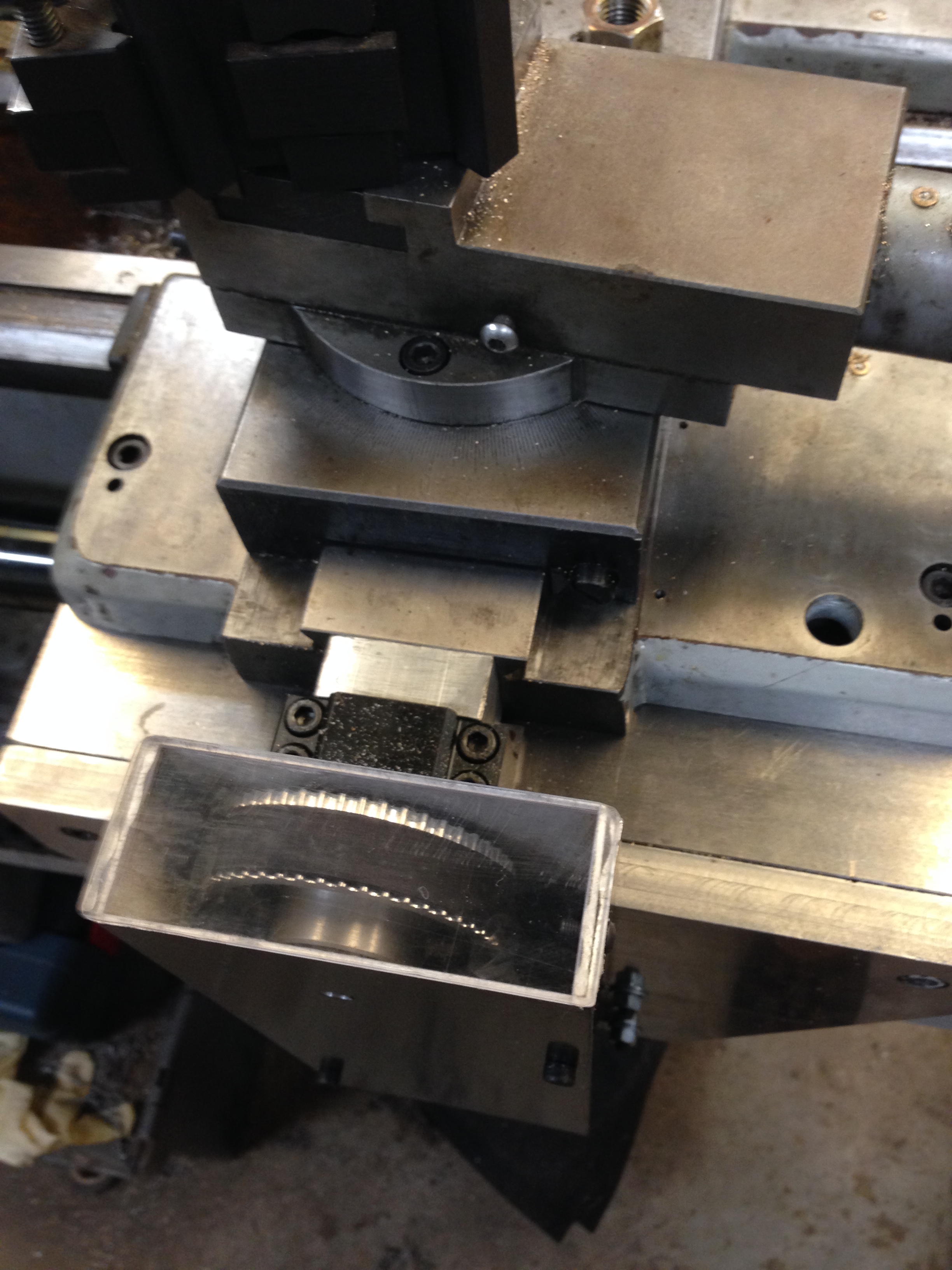

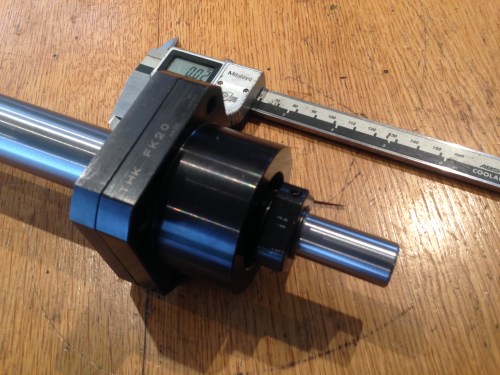

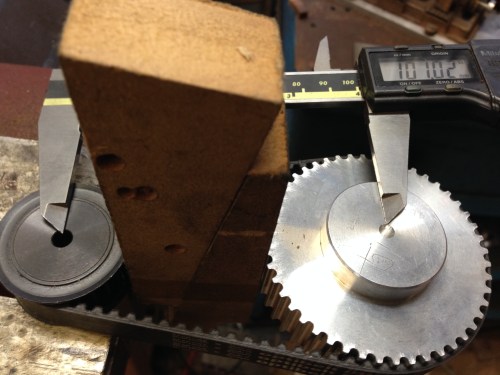

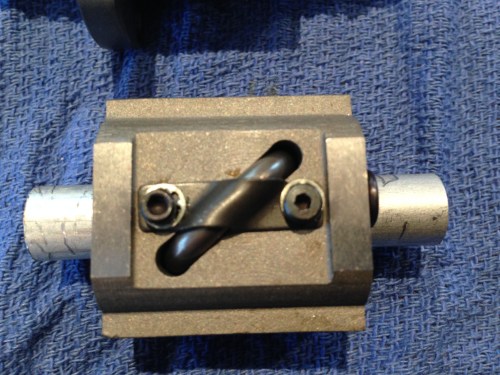

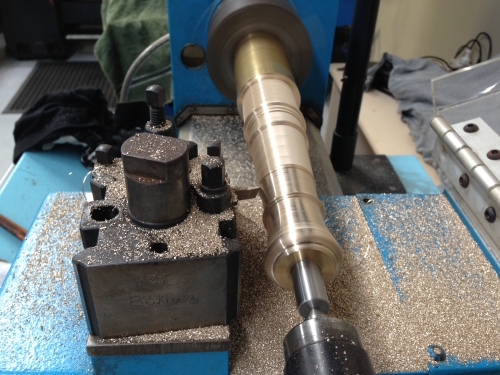

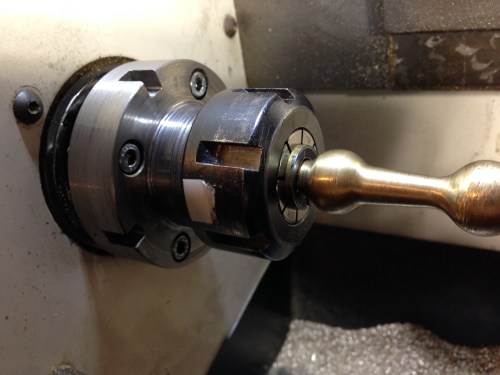

The bearing housing, toothed pulley and tapered bush.

Removed the toothed belt.

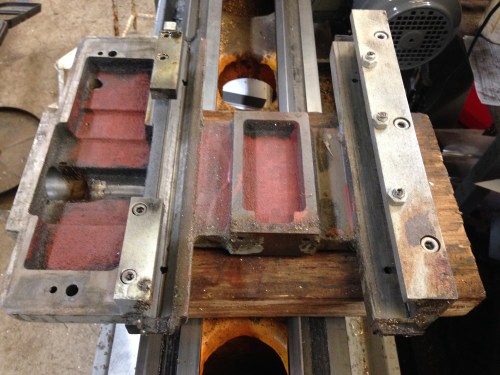

The bearing housing was next, secured by 5 large cap screws. But it would not budge, despite removal of the screws. The 2 locating pins were tightly ensconced, and persuasion was required with a series of slim wedges, hammered into the gap.

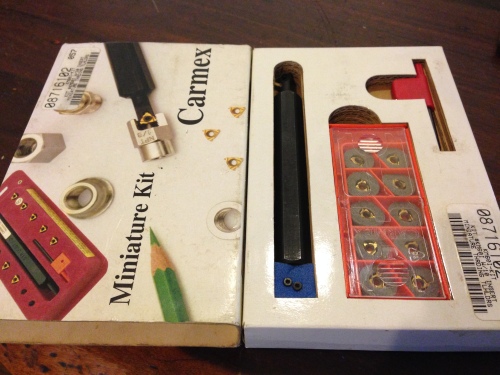

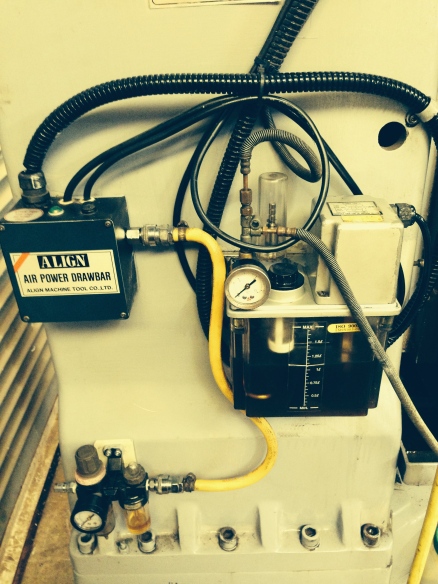

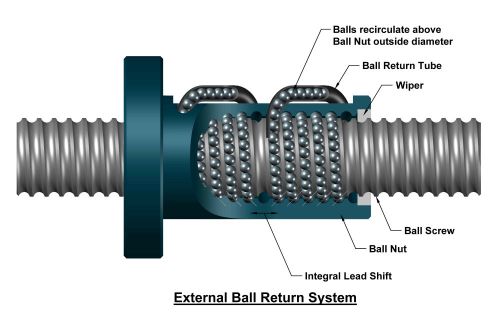

I took the cleaned up housing containing the bearing to Bob Hamilton’s Bearings and the expert there explained that there were actually 2 bearings pressed into the housing. These were angular bearings, facing each other. I thought that he would be able to tell me if they needed to be replaced, by the feel of them. Unfortunately, he explained, the only way of knowing for sure, is to actually replace them, and see if the problem is fixed.

The replacement bearings would have to be ordered at a cost of $au100, but should be delivered within 24 hours. Since my machine was out of action and of course I was in the middle of a job, I decided to insert the new bearings.

Sure enough, they arrived the next day.

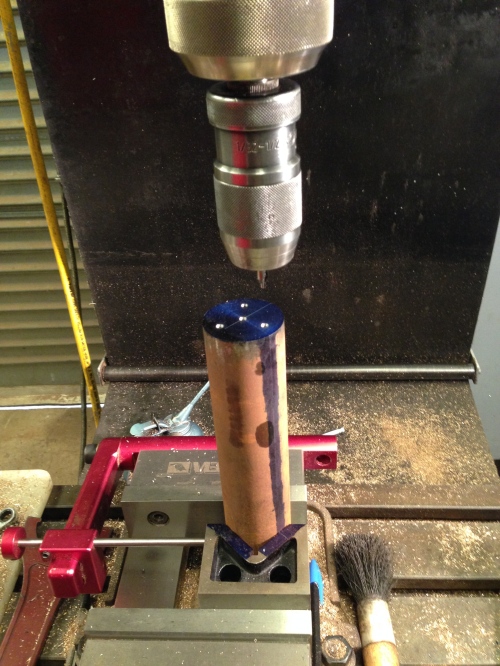

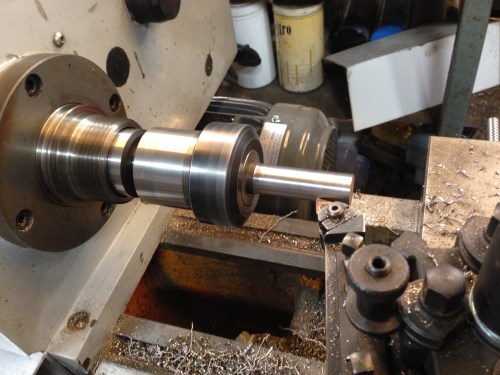

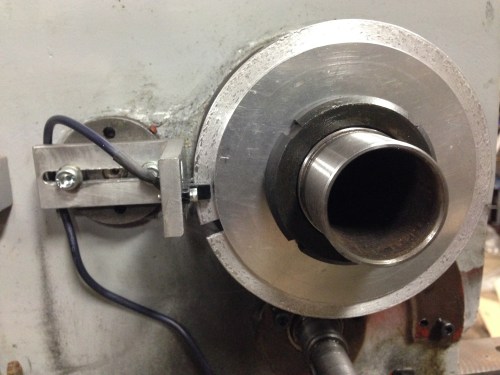

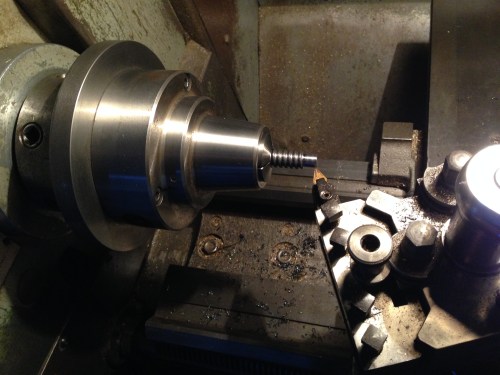

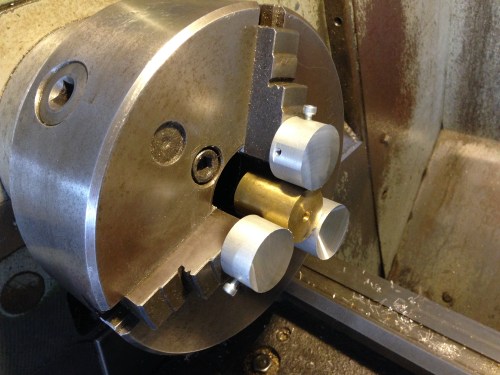

A bit nervously, I pushed out the old bearings. I made up a brass pusher to the size of the opening, and the bearings slid out fairly easily. So far so good….

The reader should be mindful that a retired gynaecologist does not have a vast experience of changing machine bearings.

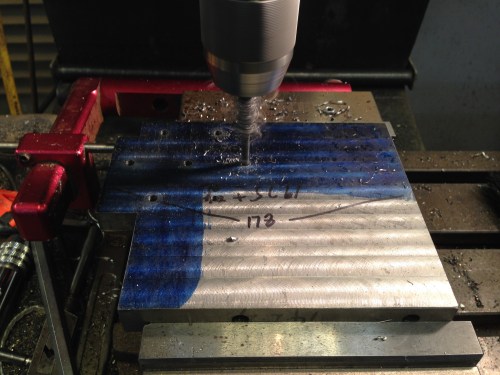

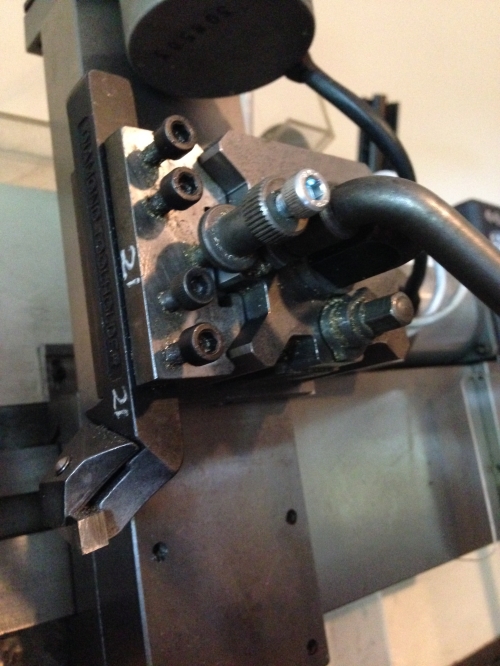

I carefully noted how the bearings were asymmetric, cleaned the cylindrical cavity and my hands, set up the press, and pushed the first bearing home.

No problem.

Except that the bearing was back to front!

Despite my careful noting of the configuration, I had managed to get it wrong. Stupid stupid stupid.

And there was now no access to the outer race of the bearing to push it out!

What to do?

I have heard of using frozen carbon dioxide to shrink bearings and make removal easier. But I have no idea how to access CO2.

The bearing slid in easily enough, so would it matter that much if I pushed on the inner race to get it out?

Oh well. WTF. If worse comes to worst I will fork out on another bearing. But maybe with a separate supplier. Just to save much embarrassment.

So I pushed on the inner race. It took more pressure than getting it inserted. Then bang!

The inner race, the ball cage, and the balls, popped out. I retrieved them all. Fortunately the balls were sizeable and easily found.

But the outer race was still stuck in the housing, and what was worse, there was no edge to push it out. Nor was there a gap at the housing base. The race was still pushed firmly home.

F**k, f**k, f**k.!!

CO2 option?? Same problem. No idea how access it.

Drill some holes through the housing to allow access for a pin punch? Ugly idea but might work. Keep that one in reserve. I really did not want to risk weakening the housing. The machine is 18 years old and I am certain that such spare parts would not be available.

Maybe I could somehow lever the race to create a gap at the base and get it started. But no access, and did not want to risk damaging the housing.

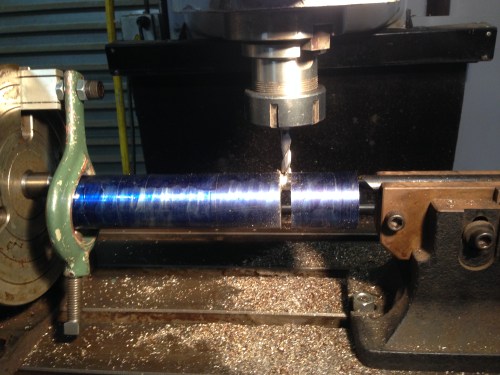

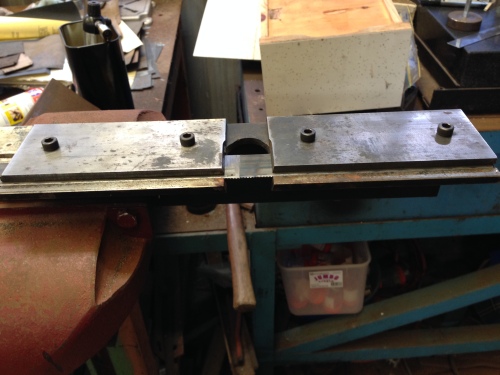

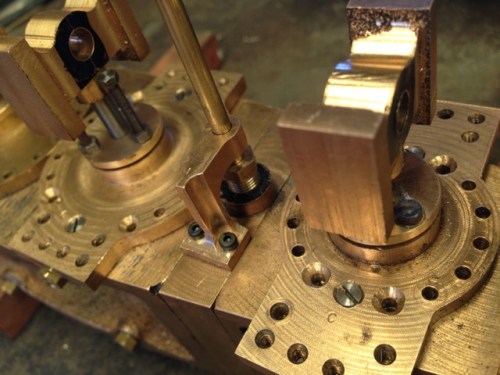

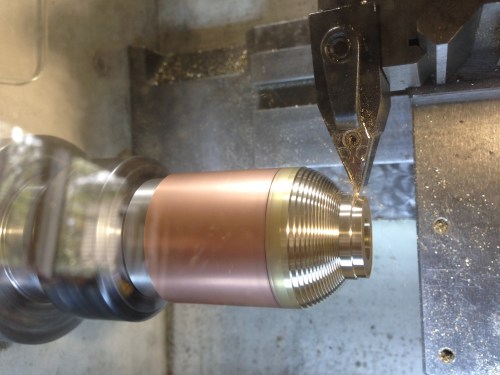

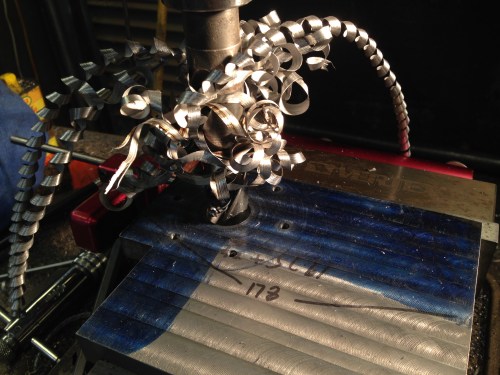

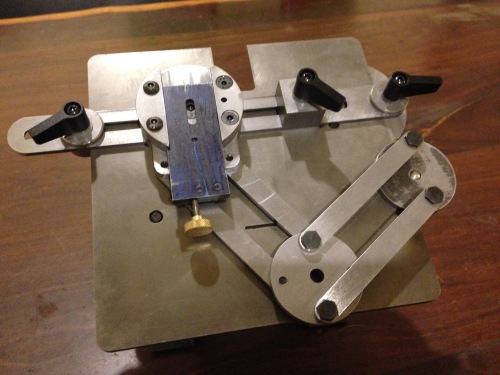

So, to cut this story short, I turned a steel disk about 5 mm thick, with a 25mm central hole, and outside diameter just to fit into the housing through the race. The disk had a knife edge. I cut the disk, to enable it to be expanded. Inserted it into the point of contact between the race and the housing, then expanded it using a pipe expander. I could have used a tapered bolt, but the pipe expander worked. As it expanded, it pushed into the slight groove between the race and the housing, then I felt the race move a little. Some further expansion, and it moved some more. Then, hallelujah, the race popped out. (I will insert some pics tomorrow).

The Pics. (added 16 Sep 2015)

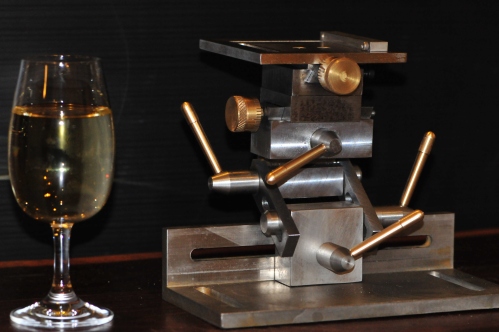

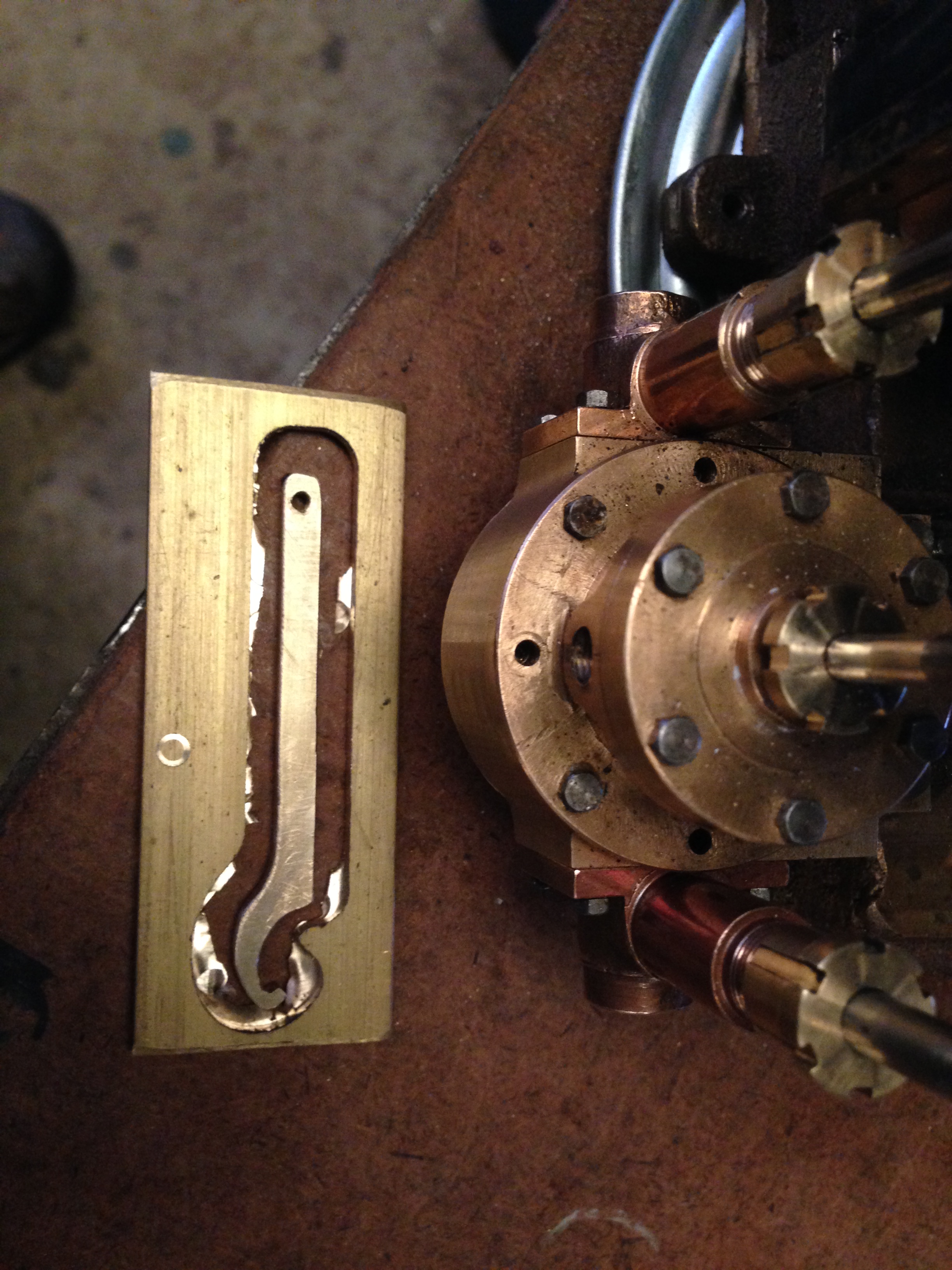

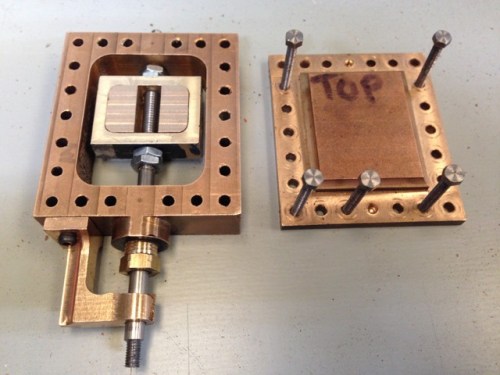

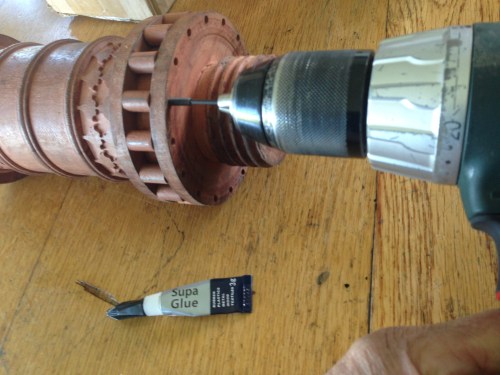

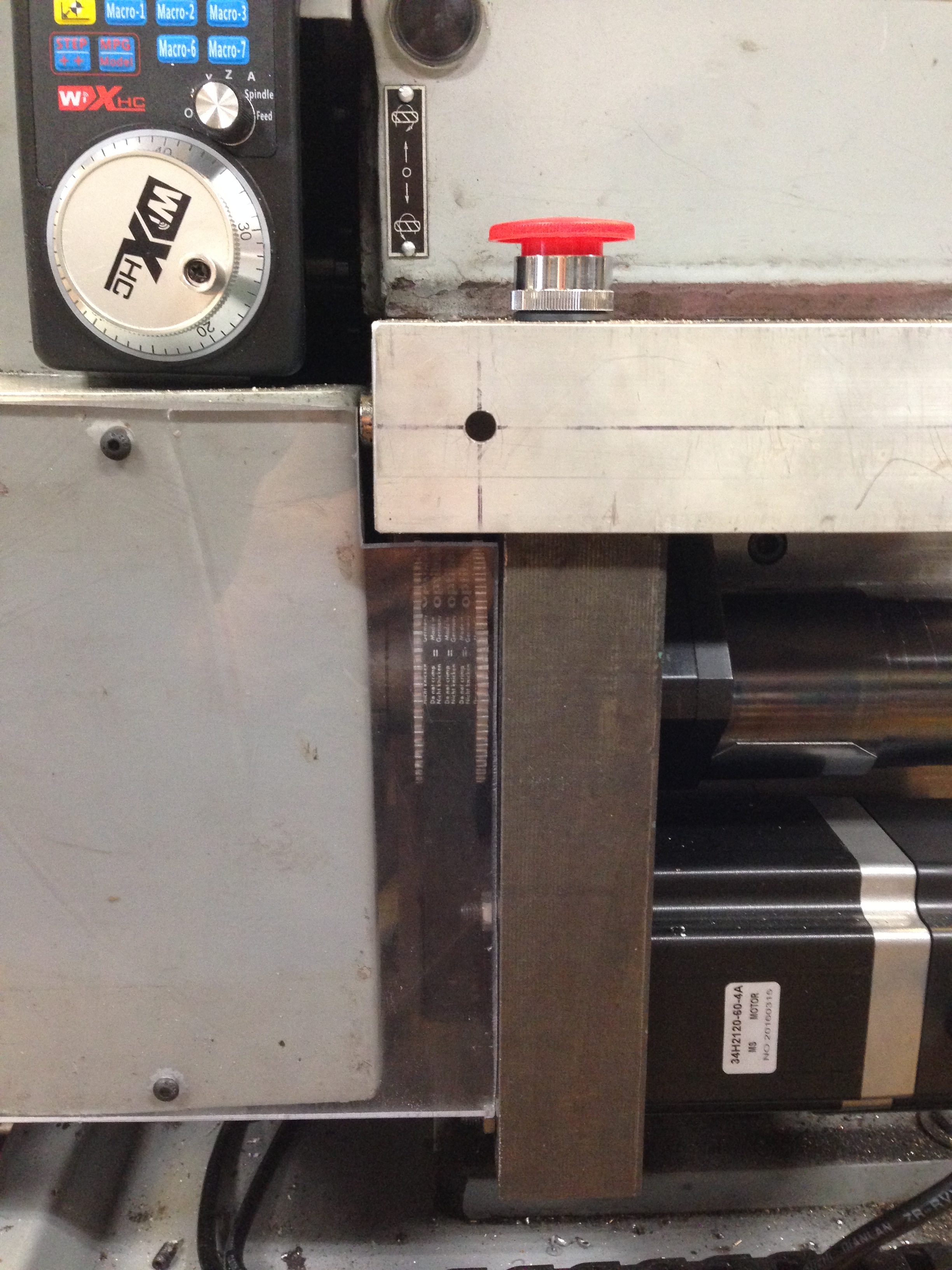

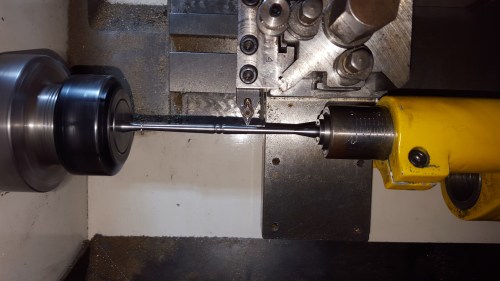

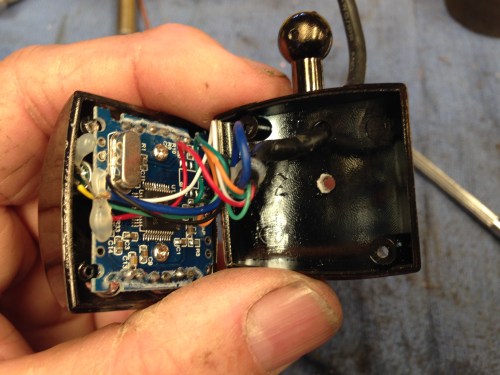

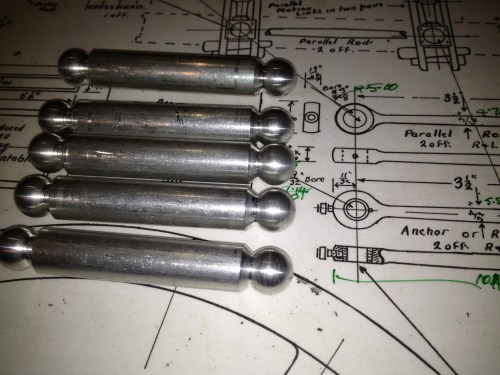

The tube expander. Usually used for joining copper pipe.

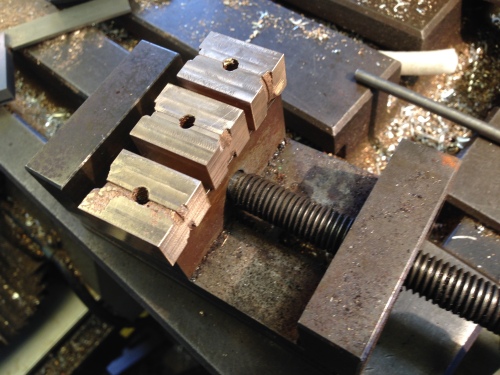

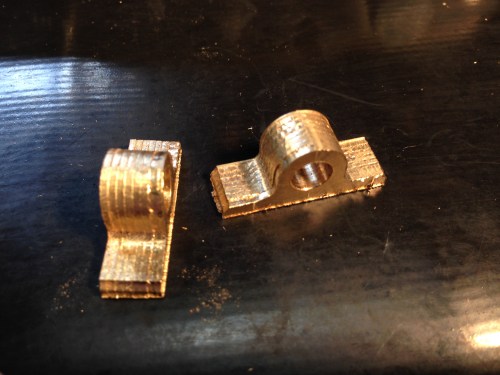

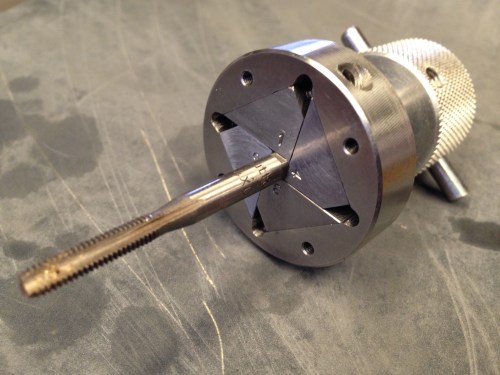

The knife edge, split ring, used to dislodge the bearing race. (seen here in its expanded state.)

Another view of the knife edge split ring, in its expanded state.

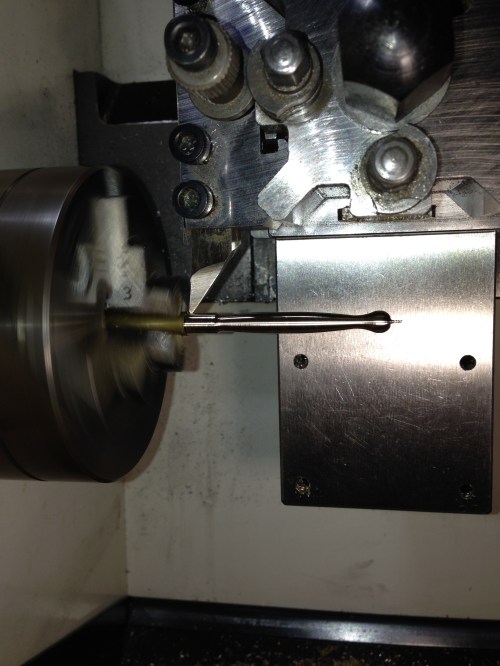

On inspecting the angle contact bearing, I could see no marks or indentations on the bearing surfaces, or the balls. So I cleaned the bits, reassembled the balls in the cage with clean grease, and pressed the assembly together in the press. It all went together with a satisfying “click”. It seemed to rotate smoothly, so I pushed the bearing back into the housing, then its partner, correctly this time.

After reassembly, I tested the machine.

It worked smoothly, and the X axis is now as silent as the other axes.

I feel stupid that I got the assembly wrong first time, but happy that it worked out in the end. And a bit chuffed that the expanding, knife edged disk idea worked! Probably reinventing the wheel. Not happy about breaking apart then pressing together the bearing. However if it becomes noisy again I will be more confident about replacing it.

I suspect that the original bearings were not actually worn, but just needed the securing nuts to be tightened. If I had tightened the securing – compressing nuts, I might have solved the problem. Oh well, live and learn. I will keep the old bearings as spares.

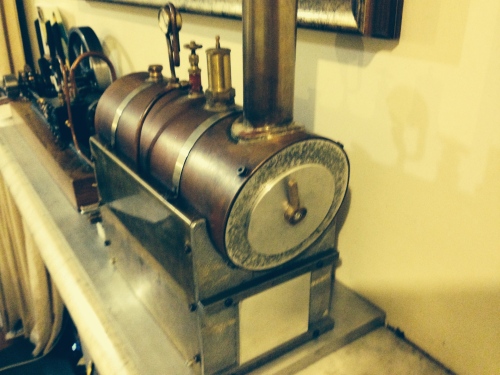

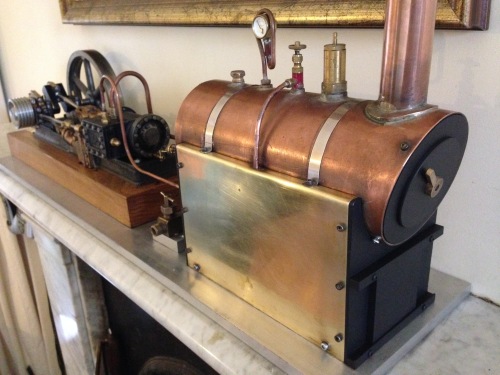

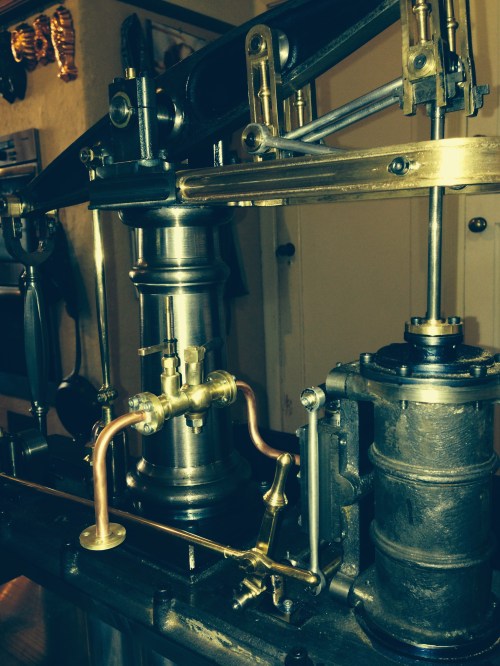

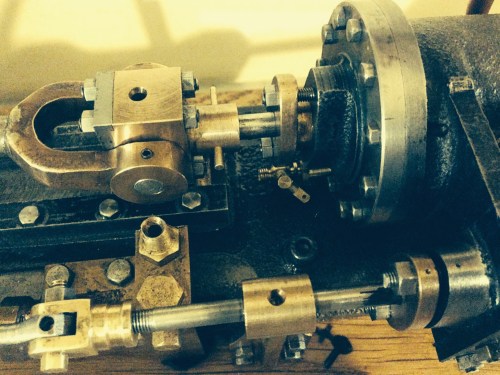

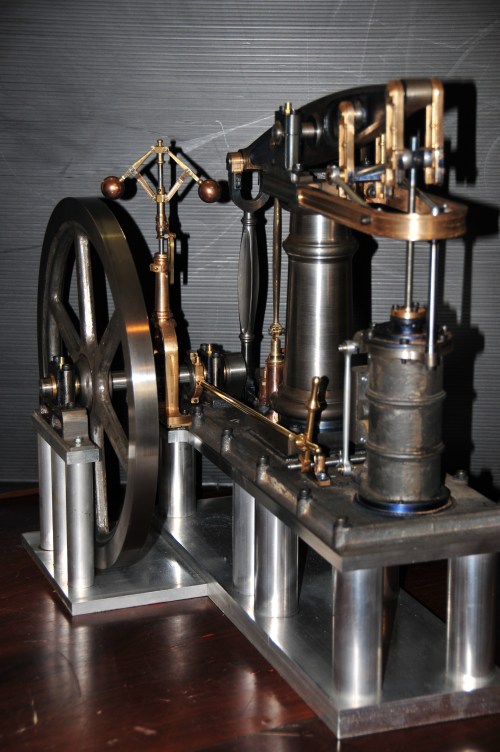

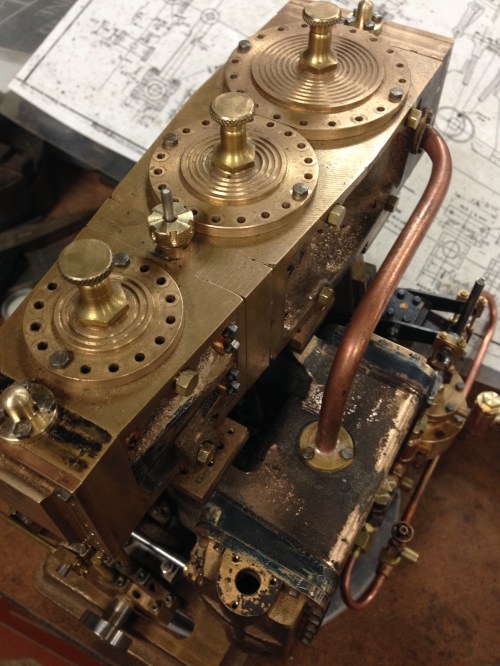

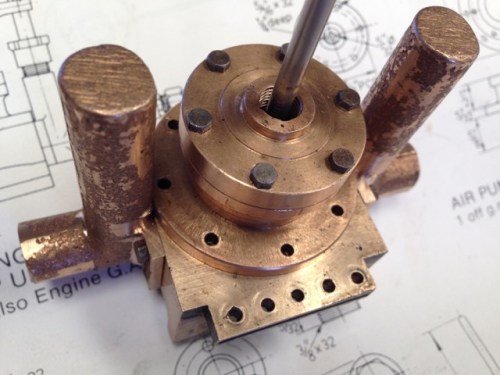

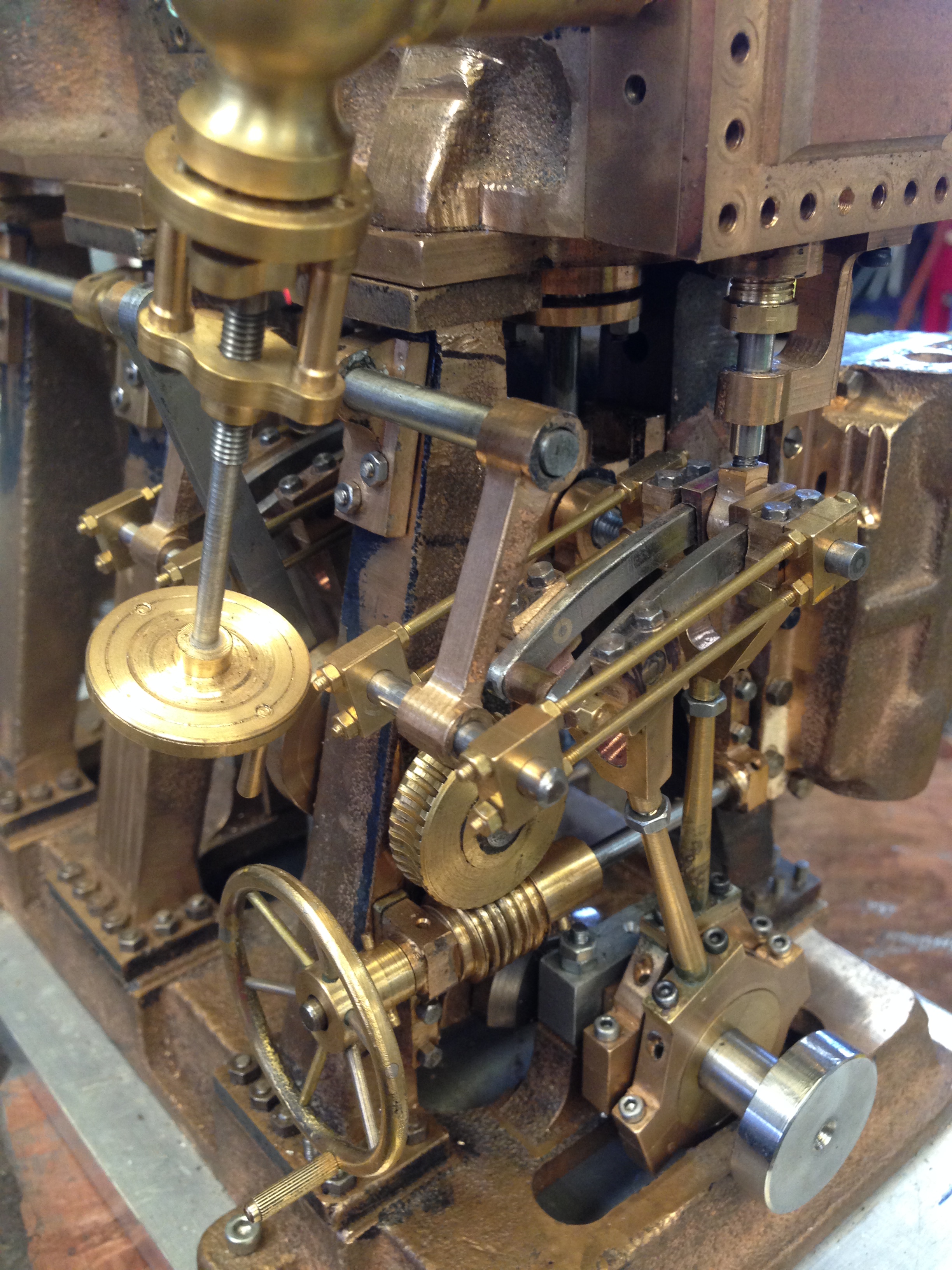

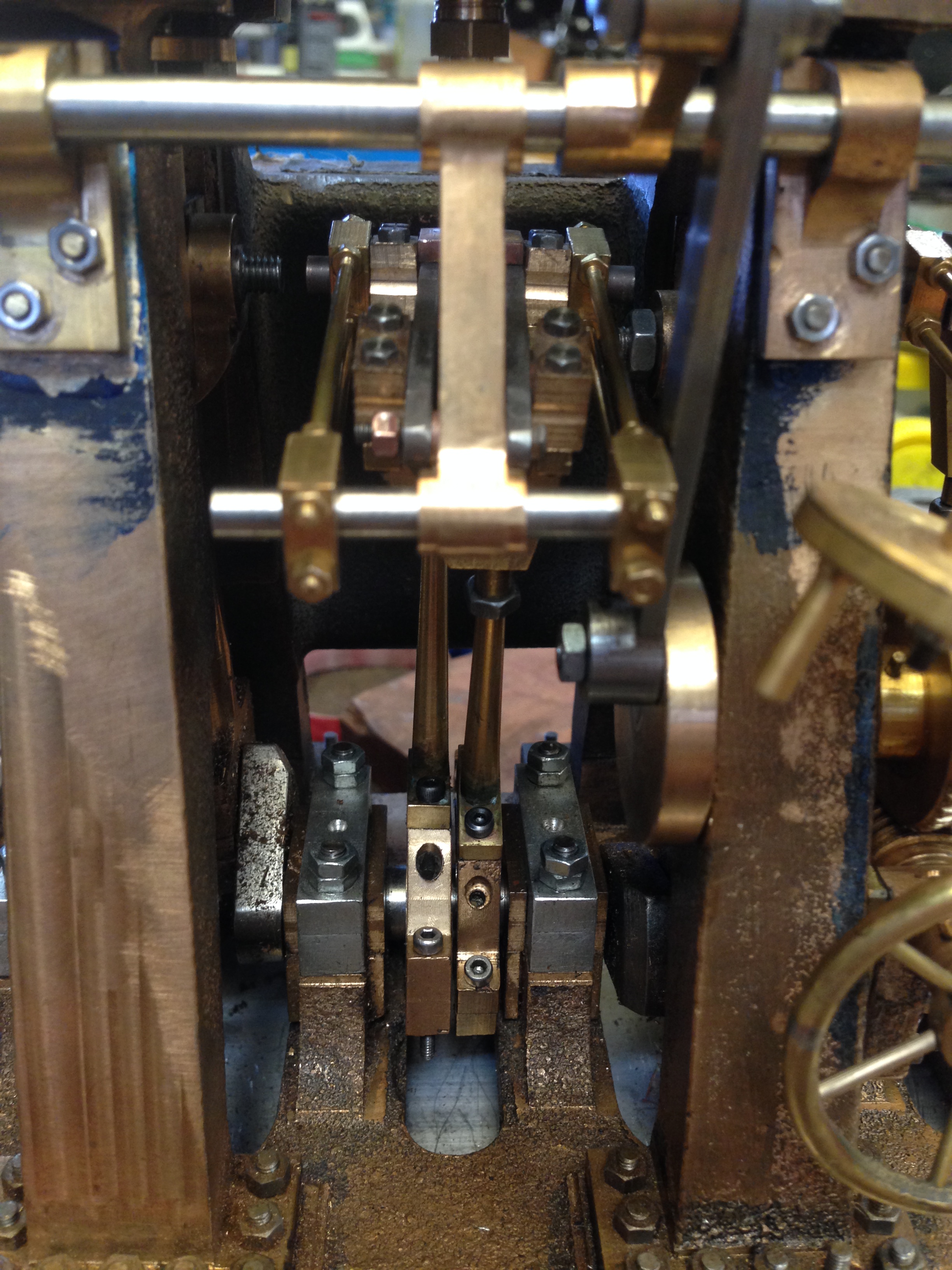

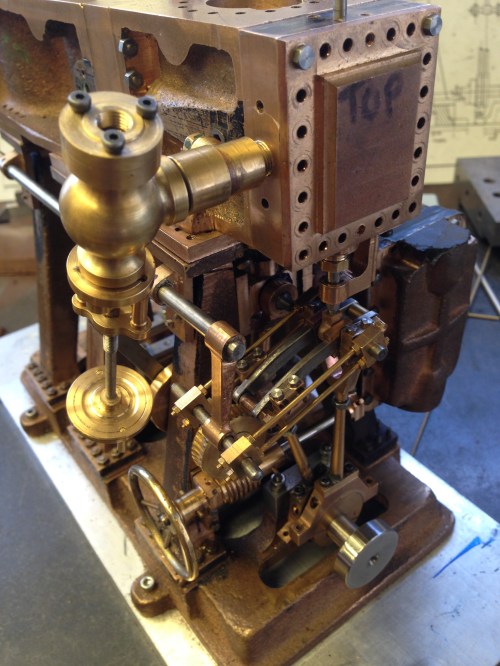

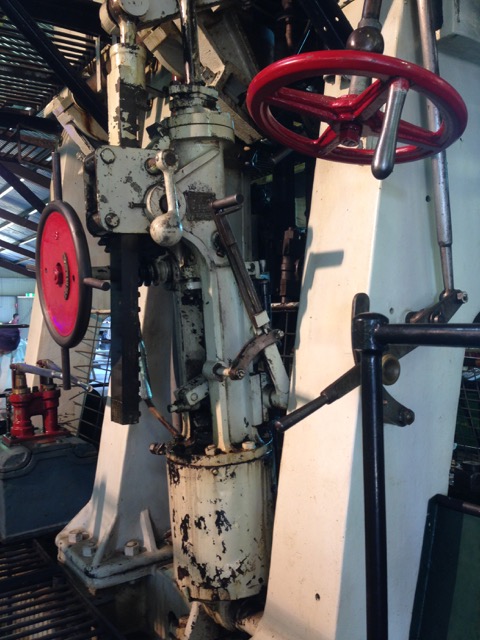

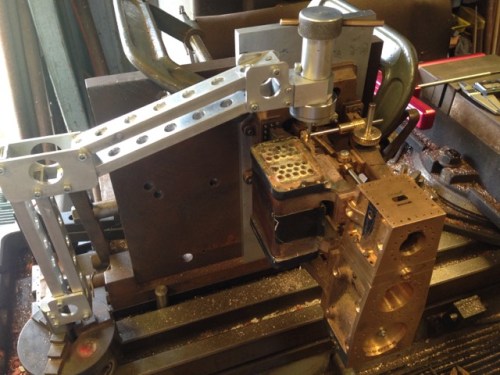

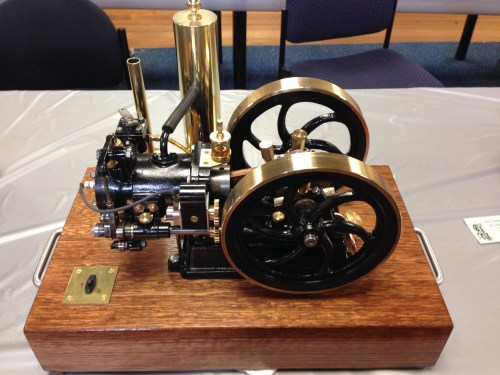

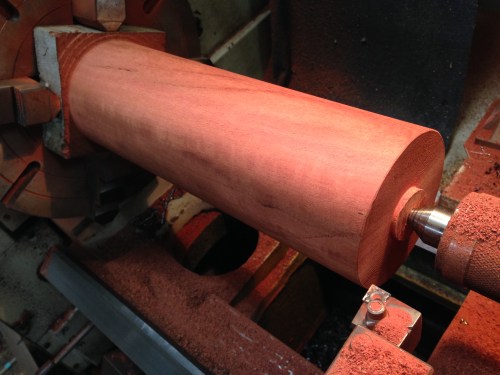

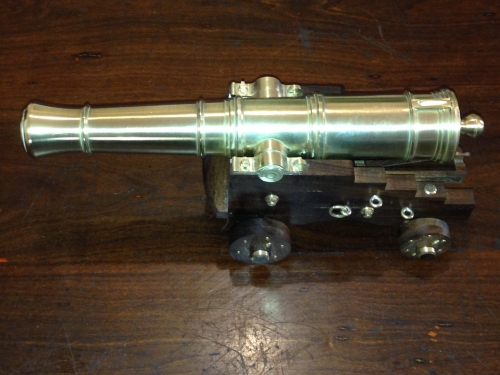

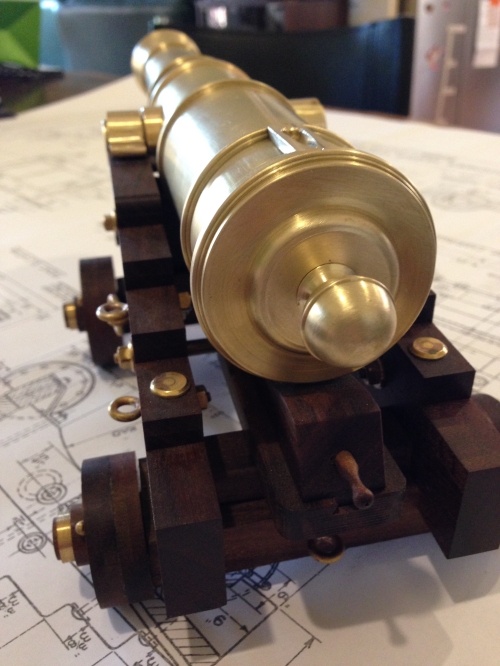

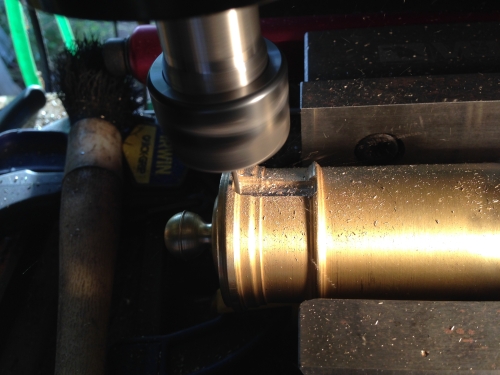

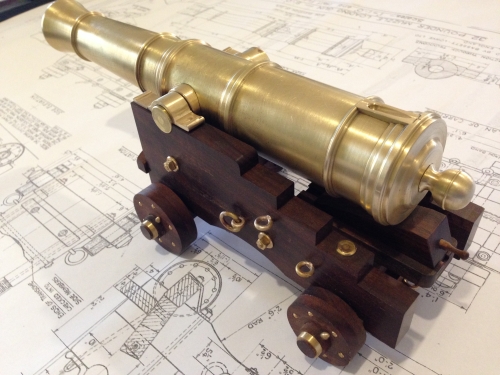

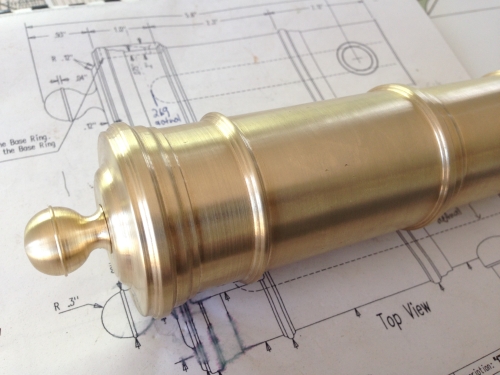

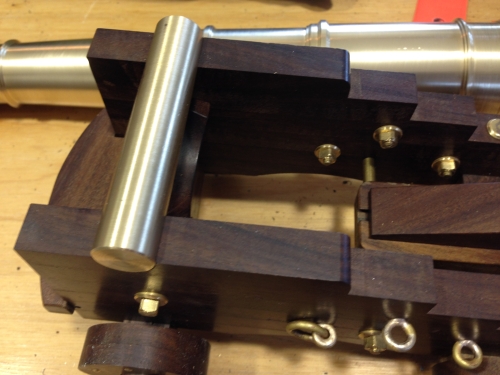

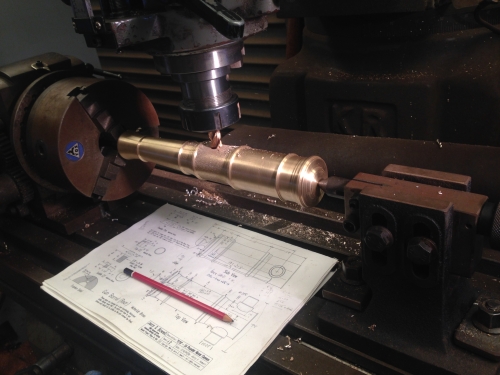

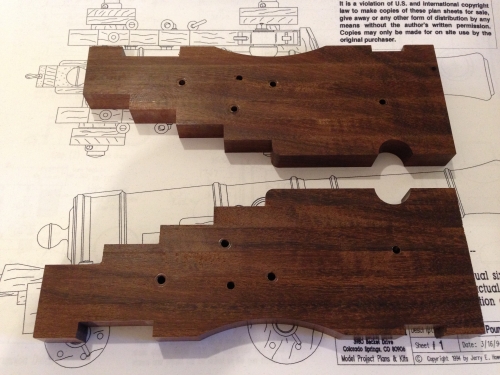

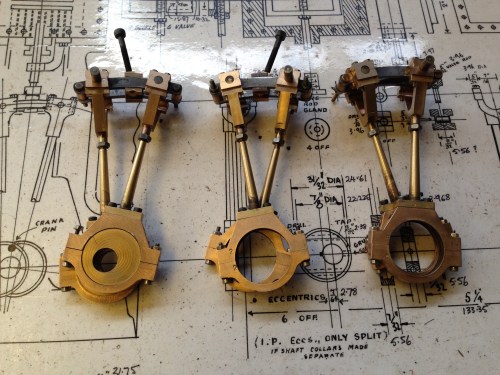

Of the many superb models on display, this one was outstanding. And totally appropriate for Bendigo, given its mining heritage.

Of the many superb models on display, this one was outstanding. And totally appropriate for Bendigo, given its mining heritage.